Custom Molded Plastic Parts: A Key Component in Manufacturing

By:Admin

The new line of Pla molded parts is made from polylactic acid, a biodegradable and compostable thermoplastic derived from renewable resources such as corn starch or sugarcane. This material offers the same strength and durability as traditional plastics, making it an ideal choice for a wide range of applications, including packaging for food, beverages, electronics, and consumer goods.

In addition to being environmentally friendly, Pla molded parts offer several benefits over conventional plastics. They are heat-resistant, making them suitable for hot-fill applications, and they have excellent barrier properties, which help to preserve the freshness and quality of packaged products. Furthermore, the biodegradable nature of Pla molded parts ensures that they do not contribute to the accumulation of plastic waste in landfills and oceans.

The launch of the new line of Pla molded parts represents a significant milestone for Pla Molded Parts Company in its commitment to sustainable packaging solutions. The company has invested heavily in research and development to create a range of products that meet the growing demand for environmentally friendly packaging options. By offering a viable alternative to traditional plastics, Pla Molded Parts Company is helping its customers reduce their environmental footprint and meet their sustainability goals.

"We are excited to introduce our new line of Pla molded parts, which represents a major advancement in sustainable packaging technology," said the CEO of Pla Molded Parts Company. "Our team has worked tirelessly to develop a product that not only meets the performance requirements of our customers but also aligns with our mission of environmental responsibility. We believe that the market is ripe for eco-friendly packaging solutions, and our Pla molded parts offer a compelling option for businesses looking to make a positive impact on the planet."

The launch of the new line of Pla molded parts also underscores Pla Molded Parts Company's ongoing commitment to innovation and quality. The company has a state-of-the-art manufacturing facility equipped with the latest technology and production processes, enabling it to deliver high-quality products that meet the needs of its customers. Furthermore, Pla Molded Parts Company has a team of experienced engineers and designers who work closely with clients to develop customized solutions that address specific packaging challenges.

"We take great pride in our ability to deliver innovative and sustainable packaging solutions to our customers," said the CEO. "Our new line of Pla molded parts is a testament to our dedication to pushing the boundaries of what is possible in the packaging industry. We are confident that this product will not only meet the needs of our clients but also make a positive impact on the environment."

As the demand for environmentally friendly packaging continues to grow, Pla Molded Parts Company is well-positioned to capitalize on this trend with its new line of Pla molded parts. The company's unwavering commitment to sustainability and innovation has cemented its reputation as a leader in the industry, and its latest product launch is further evidence of its dedication to providing cutting-edge solutions to its customers.

In conclusion, the launch of the new line of Pla molded parts by Pla Molded Parts Company represents a significant step forward in the quest for sustainable packaging solutions. With its eco-friendly and high-performance properties, these molded parts offer a compelling alternative to traditional plastics, and they are poised to make a positive impact on the environment. As businesses and consumers increasingly prioritize sustainability, Pla Molded Parts Company's latest offering is well-positioned to meet the growing demand for environmentally friendly packaging solutions.

Company News & Blog

Achieve Precision Results with Complex CNC Machining Parts

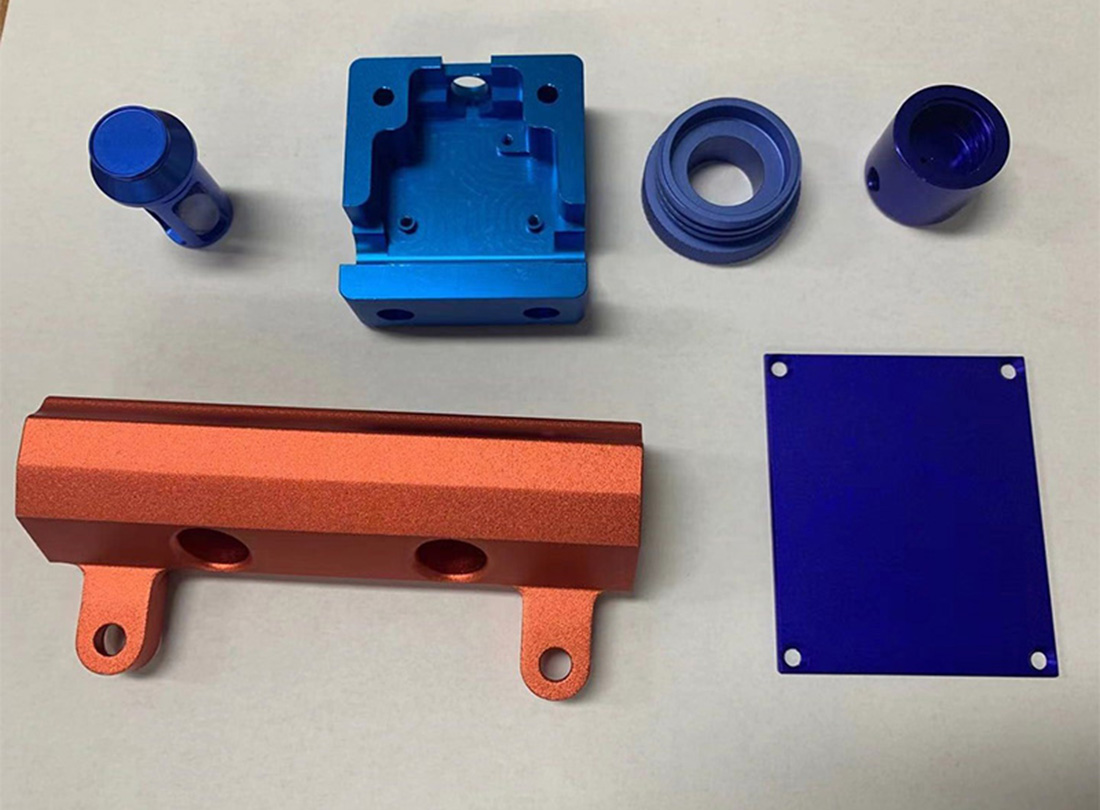

Introducing the New CNC Machining Complex PartsIn the ever-evolving world of manufacturing, precision and complexity are key factors that drive innovation and advancement. The demand for complex parts that meet the highest standards of quality and accuracy continues to grow, pushing manufacturers to seek advanced solutions to meet these requirements. With this in mind, {Company Name}, a leading provider of manufacturing solutions, is proud to introduce its new CNC Machining Complex Parts, poised to revolutionize the industry.The new CNC Machining Complex Parts from {Company Name} are designed to meet the complex needs of modern manufacturing. These parts are manufactured using state-of-the-art CNC machining technology, which allows for unparalleled accuracy, precision, and repeatability. This advanced machining process enables the production of complex parts with intricate geometries and tight tolerances, making them suitable for a wide range of industries, including aerospace, automotive, medical, and more.The CNC Machining Complex Parts offered by {Company Name} are the result of years of research, development, and innovation. The company's team of expert engineers and technicians have worked tirelessly to develop a manufacturing process that ensures the highest quality standards while also meeting the demands of today's complex manufacturing requirements. By leveraging advanced CNC machining technology, they have been able to achieve a level of precision and accuracy that was once thought to be unattainable.One of the key features of the new CNC Machining Complex Parts is their ability to produce parts with complex geometries and intricate designs. This opens up a world of possibilities for manufacturers, allowing them to create components and products that were previously deemed too complex or challenging to produce. The CNC Machining Complex Parts can also be manufactured in a wide range of materials, including aluminum, steel, titanium, and various other alloys, making them suitable for a diverse array of applications.Furthermore, the CNC Machining Complex Parts from {Company Name} are produced with efficiency and cost-effectiveness in mind. The advanced CNC machining technology allows for faster production times and lower manufacturing costs, without compromising on quality or accuracy. This makes these parts not only suitable for high-end, specialized applications, but also for large-scale production, where efficiency and cost-effectiveness are crucial considerations.{Company Name} prides itself on its commitment to quality, innovation, and customer satisfaction. The introduction of the new CNC Machining Complex Parts is a testament to this commitment, as it represents a significant leap forward in the company's capabilities and offerings. With these new parts, {Company Name} aims to provide its customers with the tools they need to stay ahead in today's competitive manufacturing landscape, offering unmatched quality, precision, and reliability.In conclusion, the new CNC Machining Complex Parts from {Company Name} are set to redefine the standards of manufacturing. By leveraging advanced CNC machining technology, the company has created a solution that meets the complex needs of modern manufacturing, offering unparalleled precision, complexity, and efficiency. With these new parts, {Company Name} continues to solidify its position as a leader in the industry, delivering innovative solutions that empower manufacturers to push the boundaries of what is possible.

The Ultimate Guide to Sheet Metal Stamping: Techniques and Applications

Sheet Metal Stamping: Revolutionizing the Manufacturing IndustryIn the fast-paced world of manufacturing, efficiency and precision are key factors that determine the success of a company. This is where the innovative technology of sheet metal stamping comes into play. Sheet metal stamping has revolutionized the manufacturing industry by providing a cost-effective and efficient method of producing high-quality metal components and parts.Sheet metal stamping, also known as pressing, is the process of creating metal parts through the use of a stamping press. The process involves placing a metal sheet into the stamping press, where a die and tooling is used to shape and cut the metal into the desired form. This method allows for the mass production of metal components with consistent quality and accuracy.One company that has been at the forefront of sheet metal stamping technology is {}. With over 20 years of experience in the industry, {} has established itself as a leading provider of sheet metal stamping services for a wide range of industries, including automotive, aerospace, electronics, and more. With state-of-the-art facilities and a team of expert engineers, {} is able to deliver high-quality stamped metal components that meet the exact specifications and requirements of their clients.The use of sheet metal stamping technology has allowed {} to offer a wide range of products and services to their customers. From simple brackets and fasteners to complex automotive and aerospace components, {} has the capability to produce a diverse array of metal parts with precision and efficiency. By utilizing advanced stamping presses and computer-aided design (CAD) software, {} is able to optimize their production processes and provide cost-effective solutions for their clients.In addition to their stamping capabilities, {} also offers value-added services such as assembly, welding, and finishing to provide comprehensive solutions for their customers. This integrated approach allows {} to streamline the manufacturing process and deliver finished products that are ready for use.Furthermore, {} is committed to sustainability and environmental responsibility in their manufacturing processes. By implementing efficient production methods and utilizing recyclable materials, {} is able to minimize waste and reduce their carbon footprint, while still delivering high-quality products to their clients.The impact of sheet metal stamping technology extends beyond just the manufacturing process. By enabling the mass production of metal components, sheet metal stamping has contributed to the advancement of various industries, including automotive, aerospace, electronics, and more. The ability to produce high-quality metal parts in large quantities has allowed companies to enhance their products and create new innovations that benefit consumers and drive industry growth.As technology continues to advance, the capabilities of sheet metal stamping are only expected to grow. With the potential for greater precision, faster production times, and expanded material options, sheet metal stamping is poised to continue revolutionizing the manufacturing industry for years to come.In conclusion, sheet metal stamping has become an indispensable technology in the manufacturing industry, and companies like {} are leading the way in delivering innovative solutions to their clients. By combining expertise, state-of-the-art facilities, and a commitment to sustainability, {} has established itself as a trusted partner for businesses seeking high-quality, cost-effective metal components. As the demand for precision-engineered metal parts continues to grow across various industries, sheet metal stamping will undoubtedly play a crucial role in shaping the future of manufacturing.

Tips for Effective Sheet Metal Bending Techniques

[Company Introduction] is a leading provider of sheet metal bending solutions in the industry. With years of expertise, state-of-the-art technology, and a commitment to excellence, we have established ourselves as a trusted partner for businesses seeking high-quality sheet metal bending services. Our team of skilled professionals is dedicated to delivering precision, efficiency, and innovation to every project, ensuring that our clients receive the best possible results.[News Content]Sheet metal bending is an essential process in the manufacturing and construction industries, with a wide range of applications across various sectors. From producing custom parts for machinery to creating intricate designs for architectural structures, sheet metal bending plays a crucial role in shaping the modern world. With advancements in technology and techniques, businesses are constantly seeking reliable partners to provide them with the sheet metal bending solutions they need to stay ahead of the competition.As a leading provider of sheet metal bending services, [Company Name] is at the forefront of this industry, offering a comprehensive range of capabilities to meet the diverse needs of our clients. Our state-of-the-art equipment, combined with our team of skilled professionals, enables us to deliver precision, quality, and efficiency in every project we undertake. Whether it's a complex, multi-step bending process or a simple, straightforward bend, our team has the expertise and resources to handle it with ease.One of the key advantages of working with [Company Name] is our ability to provide customized solutions to our clients. We understand that every project is unique, and we take the time to assess our clients' specific requirements to develop a tailored approach that meets their exact needs. From material selection and tooling design to production planning and quality control, we work closely with our clients to ensure that the final product meets their expectations in every way.In addition to our commitment to quality and customization, [Company Name] also prioritizes innovation in our sheet metal bending processes. We are constantly evaluating new technologies and techniques to improve our capabilities and expand the range of services we offer. This dedication to innovation allows us to stay ahead of industry trends and provide our clients with cutting-edge solutions that set them apart from the competition.Furthermore, [Company Name] places a high emphasis on efficiency and cost-effectiveness in our sheet metal bending services. We understand that time and budget constraints are critical factors for our clients, and we strive to deliver our solutions in a timely manner and within their budgetary requirements. Our streamlined processes and optimized workflows enable us to maximize productivity while minimizing waste, helping our clients achieve their goals without compromising on quality.As the demand for sheet metal bending solutions continues to grow across various industries, [Company Name] remains committed to being a trusted partner for businesses seeking reliable and high-quality services. With our expertise, technology, and dedication to excellence, we are well-positioned to meet the evolving needs of our clients and contribute to the success of their projects.In conclusion, sheet metal bending is an essential process with diverse applications, and [Company Name] is dedicated to providing the innovative, customized, and cost-effective solutions that businesses need to thrive in today's competitive marketplace. With our expertise, technology, and commitment to excellence, we look forward to continuing to serve as a leading provider of sheet metal bending services and contribute to the success of our clients' projects.

Ultimate Guide to High Precision CNC Lathe Machines

The high precision CNC lathe, developed by {company name}, is revolutionizing the manufacturing industry with its cutting-edge technology and advanced capabilities. This state-of-the-art machine has been designed to deliver unmatched precision, reliability, and efficiency, setting a new standard for precision manufacturing.{Company name} is a leading manufacturer of advanced CNC machinery and has been at the forefront of innovation in the industry for years. Their commitment to excellence and dedication to pushing the boundaries of what is possible has led to the development of the high precision CNC lathe, a game-changing solution for manufacturers looking to achieve the highest levels of precision and productivity.The high precision CNC lathe is equipped with advanced features and technologies that make it stand out from the competition. With its high-speed spindle and precision tooling, this machine can achieve incredibly tight tolerances and exceptional surface finishes, ensuring that every part produced meets the highest quality standards. Its robust construction and rigid design provide stability and accuracy, even when working with the most challenging materials and complex geometries.One of the key features of the high precision CNC lathe is its advanced control system, which allows for intricate and complex machining operations with ease. The machine is capable of performing a wide range of turning, drilling, and milling processes, giving manufacturers the flexibility to produce a diverse range of components with minimal setup and changeover times. This allows for increased productivity and shorter lead times, ultimately leading to a more efficient and cost-effective manufacturing process.In addition to its impressive performance capabilities, the high precision CNC lathe has been designed with the operator in mind. The machine is equipped with a user-friendly interface and intuitive controls, making it easy to program and operate. Its ergonomic design and accessibility features also contribute to a safer and more comfortable working environment, further enhancing its appeal to manufacturers looking to improve both productivity and employee satisfaction.The high precision CNC lathe is also designed to be highly adaptable, making it suitable for a wide range of applications and industries. Whether it's aerospace, automotive, medical, or any other sector that demands the highest level of precision and reliability, this machine is well-equipped to meet the needs of the most demanding manufacturing environments.{Company name} has a long-standing reputation for providing exceptional service and support to its customers, and the high precision CNC lathe is no exception. The company offers comprehensive training and ongoing technical assistance to ensure that customers can fully maximize the potential of this game-changing machine.With its unmatched precision, advanced capabilities, and user-friendly design, the high precision CNC lathe from {company name} is redefining what is possible in the world of precision manufacturing. This groundbreaking machine is setting a new standard for excellence and is poised to revolutionize the way manufacturers approach precision machining. As the industry continues to evolve, {Company name} remains at the forefront of innovation, driving progress and pushing the boundaries of what is possible with its advanced CNC machinery.

Understanding the Different Axis of a CNC Lathe Machine

In the fast-paced world of manufacturing, precision and efficiency are key factors for success. The use of advanced technology such as the CNC lathe axis has revolutionized the machining industry, allowing companies to produce high-quality components with unmatched accuracy and speed. One company that has embraced this technology is {}, a leading manufacturer of precision machined parts and components.With over 20 years of experience in the industry, {} has built a solid reputation for delivering top-notch products to a wide range of industries including aerospace, automotive, medical, and defense. Their state-of-the-art facility is equipped with the latest machinery and tools, including the latest CNC lathe axis, which has helped them stay ahead of the competition.The CNC lathe axis is a crucial component in {}'s manufacturing process, allowing them to produce complex parts with a high degree of precision. This technology enables the company to perform a wide range of machining operations, including turning, facing, threading, and drilling, all with a high level of accuracy and repeatability. With the ability to handle a variety of materials such as aluminum, steel, titanium, and plastics, {} can meet the diverse needs of their customers with ease.In addition to precision, the CNC lathe axis also offers a significant advantage in terms of efficiency. With the ability to automate the machining process, {} can produce parts at a faster rate without sacrificing quality. This not only allows them to meet tight deadlines but also helps reduce production costs, providing a competitive edge in the market.Furthermore, the use of the CNC lathe axis at {} has also improved the overall workflow and productivity of the company. With the ability to program complex shapes and geometries, the CNC lathe axis has reduced the need for manual intervention, minimizing the risk of errors and improving overall process reliability. This has allowed {} to streamline their operations and increase throughput, ultimately leading to higher customer satisfaction and improved profitability.The investment in advanced technology such as the CNC lathe axis is a testament to {}'s commitment to staying at the forefront of the industry. By continuously embracing innovation and implementing the latest machinery and tools, the company has solidified its position as a trusted partner for precision machining solutions.Moreover, the utilization of the CNC lathe axis has also allowed {} to take on a wider range of projects, from small-scale custom components to large-scale production runs. This flexibility has enabled the company to expand its customer base and take on new opportunities, further cementing its status as a leader in the industry.Looking ahead, {} remains committed to pushing the boundaries of precision machining and exploring new technologies that will continue to elevate their capabilities. By staying true to their core values of quality, innovation, and customer satisfaction, {} is well-positioned to thrive in an ever-evolving manufacturing landscape.In conclusion, the integration of the CNC lathe axis at {} has been a game-changer for the company, allowing them to produce high-quality components with unmatched precision and efficiency. As the company continues to grow and evolve, their investment in advanced technology will undoubtedly set them apart as a leader in the industry for years to come.

Durable High Heat Rubber Gasket for Industrial Use

High Heat Rubber Gasket, an Essential Component for Heat-Resistant SealingIn the world of manufacturing and industrial applications, heat-resistant sealing is a crucial element for ensuring the efficiency and safety of various equipment and machinery. High heat rubber gaskets play a significant role in providing the necessary sealing solutions for high-temperature environments, making them an essential component in a wide range of applications. As a leading provider of high-quality high heat rubber gaskets, {} is dedicated to delivering innovative and reliable sealing solutions that meet the demands of the most challenging industrial environments.With a strong focus on quality and performance, {} has established itself as a trusted supplier of high heat rubber gaskets, serving a diverse range of industries including automotive, aerospace, energy, and manufacturing. The company’s commitment to excellence is reflected in its ability to develop and produce high heat rubber gaskets that meet the stringent requirements of these demanding industries.One of the key factors that set {} apart from its competitors is its advanced manufacturing capabilities. The company utilizes state-of-the-art equipment and advanced manufacturing processes to produce high heat rubber gaskets that are not only capable of withstanding extreme temperatures but also offer superior resilience and durability. This allows {} to offer its customers high heat rubber gaskets that provide long-lasting and reliable performance in the most demanding applications.In addition to the company’s manufacturing capabilities, {} places a strong emphasis on innovation and research and development. Its team of skilled engineers and materials experts work tirelessly to develop new and improved high heat rubber gaskets that offer enhanced performance and reliability. By staying at the forefront of technological advancements, {} is able to offer its customers cutting-edge sealing solutions that meet the evolving needs of modern industry.The high heat rubber gaskets offered by {} are designed to provide a secure and reliable seal in applications where elevated temperatures and harsh operating conditions are present. These gaskets are specially formulated to withstand temperatures ranging from -50°C to 300°C, making them ideal for use in environments where traditional rubber gaskets would fail. Additionally, {} offers a variety of high heat rubber gaskets in different shapes, sizes, and materials, ensuring that its customers can find the perfect sealing solution for their specific needs.With a strong focus on customer satisfaction, {} is committed to providing exceptional service and support to its customers. The company works closely with its clients to understand their unique sealing challenges and offers tailored solutions that meet their exact requirements. Whether it’s providing custom-designed high heat rubber gaskets or offering technical assistance and guidance, {} goes above and beyond to ensure that its customers receive the best possible sealing solutions.In conclusion, high heat rubber gaskets are a crucial component for ensuring effective sealing in high-temperature environments. As a leading provider of high-quality high heat rubber gaskets, {} is dedicated to delivering innovative sealing solutions that meet the demands of the most challenging industrial applications. With its advanced manufacturing capabilities, focus on innovation, and commitment to customer satisfaction, {} is well-positioned to continue providing reliable and high-performance high heat rubber gaskets to its customers around the world.

Get the Latest Insights and Updates on Injection Molding Techniques

[Company Name] Revolutionizes the Injection Molding Industry with Cutting-Edge Technology[Location, Date] - [Company Name], a leading provider of innovative manufacturing solutions, is transforming the injection molding industry with their state-of-the-art technology and unwavering commitment to excellence. With a focus on efficiency, quality, and sustainability, [Company Name] is revolutionizing the way products are manufactured through their advanced injection molding processes.Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to create complex shapes with great precision. Traditionally, injection molding has been associated with long cycle times, high costs, and limitations in design flexibility. However, [Company Name] has successfully addressed these challenges and developed innovative solutions that have propelled the industry forward.At the heart of [Company Name]'s success lies their cutting-edge injection molding machine, which boasts enhanced speed, accuracy, and repeatability. This state-of-the-art equipment allows for faster cycle times, increasing production capacity while reducing costs. Additionally, the machine's high precision ensures consistent quality and product integrity, meeting even the most stringent industry standards.Furthermore, [Company Name] has revolutionized the injection molding process by offering an extensive range of materials, including environmentally-friendly options. By incorporating sustainable materials into their manufacturing process, [Company Name] is playing a vital role in reducing the industry's carbon footprint. This commitment to sustainability aligns with the growing consumer demand for eco-conscious products and fosters a greener future for the manufacturing industry.The company's injection molding technology also enables unmatched design flexibility, allowing customers to create intricate designs and incorporate complex features into their products. With the ability to produce parts with varying sizes, shapes, and textures, [Company Name] empowers businesses to differentiate their offerings and stay ahead of their competitors in today's fast-paced marketplace.One of the key advantages of [Company Name]'s injection molding technology lies in its ability to produce parts with exceptional precision, requiring minimal post-production modifications. This not only reduces costs but also accelerates time to market, giving businesses a competitive edge. Moreover, [Company Name]'s commitment to continuous improvement means that their injection molding process is constantly evolving, embracing the latest advancements in technology.In addition to their cutting-edge manufacturing solutions, [Company Name] also offers comprehensive support throughout the entire production cycle. From initial design consultation to final product delivery, their team of experts collaborates closely with customers to ensure that their unique needs and specifications are met. This personalized approach, combined with their industry-leading technology, has earned [Company Name] a reputation for excellence and customer satisfaction.As a testament to their success, [Company Name] has established long-standing partnerships with numerous prestigious clients in industries such as automotive, aerospace, electronics, and consumer goods. Their unwavering commitment to quality, efficiency, and innovation has allowed them to become a trusted partner for companies seeking reliable and high-performing injection molding solutions.Looking ahead, [Company Name] continues to invest in research and development to further advance their injection molding technology. Their dedication to pushing the boundaries of what is possible in the manufacturing industry positions them as a frontrunner in innovation. With a steadfast commitment to sustainability, design flexibility, precision, and customer satisfaction, [Company Name] is set to revolutionize the injection molding industry for years to come.

Exploring the Benefits of Aluminum Injection Molding in Today's Manufacturing Industry

[Assistant]Title: Revolutionizing Manufacturing: Aluminum Injection Molding Sets New Industry StandardsIntroduction:Innovation continues to be the driving force behind advancements in the manufacturing industry. Among the latest breakthroughs is the revolutionary technique of aluminum injection molding. This cutting-edge manufacturing process has the potential to reshape various sectors by providing unique advantages such as cost-effectiveness, increased design flexibility, and enhanced production efficiency. In this article, we delve into the details of aluminum injection molding, exploring its benefits, applications, and the promising future it holds.Understanding Aluminum Injection Molding:Aluminum injection molding is an advanced manufacturing technique that combines the versatility of plastic injection molding with lightweight and durable aluminum materials. This process involves injecting molten aluminum under high pressure into complex and intricate molds, allowing for the creation of intricate parts and components with exceptional precision. The process takes advantage of the desirable properties of aluminum, including its high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity.The Company's Role:The trailblazers in aluminum injection molding technology, [Company Name], have been at the forefront of the industry, leading in research, development, and implementation of this groundbreaking method. Their extensive experience and cutting-edge facilities have enabled them to refine and perfect the aluminum injection molding process, making it highly efficient and adaptable to various manufacturing requirements. The company's dedication to continuous innovation has positioned them as a driving force behind the widespread adoption of aluminum injection molding.Applications and Industries Transformed:The advent of aluminum injection molding has had a transformative impact across numerous industries, offering a wide range of applications and benefits. In the automotive sector, lightweight aluminum components produced through this process have revolutionized vehicle design, leading to improved fuel efficiency, better performance, and enhanced safety. Similarly, aerospace manufacturers are benefiting from the lightweight properties of aluminum injection-molded parts, resulting in reduced fuel consumption and increased payload capabilities.Electronics and telecommunications industries can leverage the design flexibility of aluminum injection molding to create intricate and high-performance electronic enclosures and housings. The process also allows for the integration of additional features, such as heat sinks, resulting in improved thermal management and extended device lifespans.The medical field is yet another sector where aluminum injection molding can make a profound impact. The ability to produce complex and sterile medical devices and implants made from lightweight yet durable aluminum materials opens new possibilities for enhanced patient care, improved surgical outcomes, and cost-effective medical solutions.Benefits Driving Adoption:The widespread adoption of aluminum injection molding can be attributed to the numerous benefits it offers. One of the most significant advantages is the cost-effectiveness of the process. By utilizing aluminum materials, which are relatively inexpensive, manufacturers can produce lightweight yet strong components without breaking the bank. This affordability extends to the tooling process as well, as aluminum molds are generally less costly than traditional injection molding molds.Moreover, aluminum injection molding enables manufacturers to achieve intricate and precise designs that were previously unattainable. The ability to create complex geometries with exceptional accuracy allows for the integration of multiple functions into a single part, reducing assembly time and enhancing overall product performance.Furthermore, the lightweight nature of aluminum components facilitates transportation and logistics, ultimately reducing costs and environmental impact. Aluminum's corrosion resistance properties also ensure long-lasting durability, making it an ideal choice for applications exposed to harsh environments or demanding conditions.The Path Towards a Promising Future:As aluminum injection molding continues to gain traction, researchers and manufacturers are working collaboratively to push its boundaries further. The ongoing advancement of this technology aims to enhance process efficiency, minimize cycle times, and explore possibilities for new alloy variants. Additionally, efforts are being made to streamline post-processing techniques such as surface treatments and finishing processes to ensure the highest quality standards.Industry experts predict that aluminum injection molding will play a pivotal role in the wider adoption of electric vehicles, thanks to the efficiency gains and material advantages it offers. Furthermore, as sustainability and lightweighting remain key focus areas for many industries, aluminum injection molding will likely continue to grow, revolutionizing diverse sectors such as consumer electronics, renewable energy, and industrial manufacturing.Conclusion:Aluminum injection molding represents a transformative leap in the manufacturing industry. This innovative technique has revolutionized product design and production, with its cost-effectiveness, design flexibility, and lightweight yet durable results. Spearheaded by industry leaders like [Company Name], aluminum injection molding is poised to reshape diverse sectors, promising a future characterized by enhanced efficiency, improved performance, and sustainable manufacturing practices. As research and development continue to progress, the prospects for this revolutionary method are boundless.

How CNC Plastic Machining Prototypes Can Accelerate Product Development

CNC Plastic Machining Prototype is a cutting-edge technology that has revolutionized the manufacturing industry. This innovative process allows companies to create high-quality plastic prototypes with a high level of precision and accuracy. With the ability to produce complex shapes and designs, CNC plastic machining prototype has become an essential tool for companies looking to develop new products and test their ideas before full-scale production.One company that is leading the way in CNC plastic machining prototype is {}. Specializing in precision manufacturing and rapid prototyping, {} has established itself as a trusted partner for businesses looking to bring their product ideas to life. By leveraging the latest CNC technology and a team of highly skilled engineers, {} delivers top-quality plastic prototypes that meet the exact specifications of their clients.CNC plastic machining prototype offers a wide range of benefits for companies across various industries. One of the key advantages of this technology is the ability to create prototypes with intricate details and complex geometries. This level of precision is essential for companies developing products in industries such as aerospace, automotive, medical devices, and consumer electronics. With CNC plastic machining prototype, companies can test their designs and make adjustments before committing to full production, ultimately saving time and costs in the long run.In addition to its precision, CNC plastic machining prototype is also known for its speed and efficiency. Traditional methods of prototype production often involve time-consuming processes and manual labor, leading to longer lead times and higher costs. With CNC technology, {} is able to produce plastic prototypes in a fraction of the time, allowing their clients to iterate and refine their designs quickly and effectively.Furthermore, CNC plastic machining prototype is versatile and can accommodate a wide range of plastic materials. Whether it's ABS, polyethylene, polycarbonate, or any other type of plastic, {} has the expertise and capabilities to machine prototypes that meet the specific needs of their clients. This flexibility enables companies to explore different material options and identify the best fit for their final product, ensuring optimal performance and functionality.As a leading provider of CNC plastic machining prototype, {} is committed to delivering exceptional quality and customer satisfaction. Their team of engineers works closely with clients to understand their unique requirements and develop prototypes that exceed expectations. With a focus on continuous improvement and innovation, {} is dedicated to staying at the forefront of CNC technology and offering the best solutions for their clients' prototyping needs.In conclusion, CNC plastic machining prototype has emerged as a game-changing technology for companies looking to develop high-quality plastic prototypes. With its precision, speed, efficiency, and versatility, CNC technology has become an essential tool for businesses across various industries. As a trusted partner in precision manufacturing and rapid prototyping, {} continues to lead the way in delivering top-quality plastic prototypes that help their clients bring their product ideas to life.

Ultimate Guide to Precision Automatic Lathe: Everything You Need to Know

Precision Automatic Lathe (PAL) is an important and efficient machine in the manufacturing industry that plays a crucial role in producing high-precision components for various products. With its advanced technology and precision engineering, PAL has become a valuable asset for companies looking to streamline their manufacturing processes and improve product quality.{Company name} is a leading manufacturer of precision parts and components for a wide range of industries, including automotive, aerospace, electronics, and medical devices. The company has been at the forefront of innovation and technology, continuously investing in state-of-the-art equipment and machinery to meet the growing demand for high-precision parts. As part of its commitment to excellence, {Company name} has recently incorporated the latest Precision Automatic Lathe into its production line, further enhancing its capabilities and delivering exceptional quality to its customers.The Precision Automatic Lathe is a versatile and highly efficient machine that is capable of producing complex and intricate parts with tight tolerances. It is equipped with advanced features such as computer numerical control (CNC) technology, automatic tool changers, and high-speed machining capabilities, allowing for the production of precise components with minimal human intervention. This level of automation not only improves efficiency and productivity but also ensures consistency and accuracy in the manufacturing process.One of the key advantages of using Precision Automatic Lathe is its ability to handle high-volume production runs without sacrificing quality. With its fast and precise machining capabilities, the machine is capable of producing a large number of parts in a short amount of time, making it an ideal solution for companies with strict production deadlines and high demand for their products. This translates to faster turnaround times and increased productivity, ultimately leading to cost savings and improved competitiveness in the market.Additionally, the Precision Automatic Lathe offers versatility in terms of the types of materials it can work with. Whether it is metal, plastic, or composite materials, the machine is designed to accommodate a wide range of materials, making it a flexible and adaptable solution for various manufacturing requirements. This capability allows companies like {Company name} to diversify their product offerings and cater to different industries and applications, further expanding their market reach and opportunities for growth.By integrating the Precision Automatic Lathe into its production line, {Company name} is poised to elevate its manufacturing capabilities and deliver even higher quality products to its customers. The machine's precision and reliability will enable the company to meet the stringent requirements of its clients and exceed their expectations, solidifying its reputation as a trusted supplier of precision parts and components.Furthermore, the adoption of advanced technology such as Precision Automatic Lathe aligns with {Company name}'s commitment to continuous improvement and innovation. By staying at the forefront of technological advancements, the company is able to stay ahead of the competition and maintain its position as a leader in the industry. This investment in cutting-edge machinery demonstrates {Company name}'s dedication to meeting the evolving needs of its customers and providing them with the best possible solutions for their manufacturing requirements.In conclusion, the integration of Precision Automatic Lathe into {Company name}'s production line represents a significant milestone for the company and its commitment to delivering exceptional quality and precision to its customers. The machine's advanced capabilities and automation will not only streamline the manufacturing process but also enhance the company's ability to meet the demands of a rapidly evolving market. As {Company name} continues to invest in advanced technology and innovation, it is poised to achieve even greater success and solidify its position as a leading manufacturer of precision parts and components.