Silicone Rubber Parts: Latest Developments in High-Quality Manufacturing

Silicone Rubber Parts Revolutionizing Industries: An Introduction to [Company Name][City, Date] - Silicone rubber parts have emerged as a revolutionary solution across a wide range of industries, providing unparalleled versatility and performance. [Company Name] has been at the forefront of this innovation, offering cutting-edge silicone rubber parts that are transforming various sectors. With a commitment to delivering superior quality and unmatched customer satisfaction, [Company Name] has become a trusted name in the silicone rubber industry.Since its establishment [number of years] ago, [Company Name] has dedicated itself to research, development, and production of high-quality silicone rubber parts. Backed by a team of experienced engineers and designers, the company continues to push boundaries and redefine the possibilities of silicone rubber applications. Their relentless pursuit of innovation has paved the way for groundbreaking solutions in industries such as automotive, electronics, healthcare, aerospace, and many more.The automotive industry, in particular, has witnessed remarkable advancements in the use of silicone rubber parts. From gaskets and seals to custom molded components, silicone rubber offers exceptional resistance to temperature, chemicals, and wear. [Company Name] has been instrumental in providing automotive manufacturers with tailor-made solutions that enhance performance, durability, and safety.In the electronics sector, where precision and reliability are of utmost importance, silicone rubber parts from [Company Name] play a vital role. These parts are instrumental in protecting sensitive electronic components from harsh environments, such as moisture, dust, and vibration. They also provide excellent electrical insulation properties, ensuring the longevity and functionality of electronic devices.Furthermore, the healthcare industry has seen a surge in the adoption of silicone rubber parts due to their biocompatibility and sterilization capabilities. Silicone rubber has become the material of choice for medical devices, implants, and equipment, thanks to its hypoallergenic nature and resistance to bacteria growth. [Company Name]'s expertise in this field has helped healthcare professionals and patients alike, ensuring the highest standards of safety and performance.Silicone rubber parts developed by [Company Name] have found their way into the aerospace industry as well. With stringent requirements for high-temperature resistance and durability, silicone rubber parts offer unmatched reliability in critical aerospace applications. Whether it's seals for engines, gaskets for compartments, or vibration-dampening mounts, [Company Name] has demonstrated its ability to meet and exceed the demands of this challenging industry.What sets [Company Name] apart from others in the market is its commitment to customization. The company understands that every industry and application has unique requirements, and a one-size-fits-all approach simply won't suffice. With state-of-the-art manufacturing facilities and advanced production techniques, [Company Name] ensures that each silicone rubber part is precisely engineered to the customer's exact specifications.Moreover, [Company Name] places emphasis on quality control, adhering to the highest industry standards. Rigorous testing procedures and inspections are carried out at every stage of the production process, guaranteeing that only flawless silicone rubber parts reach the customers. This unwavering commitment to quality has earned [Company Name] a reputation for excellence and reliability in the industry.Looking ahead, [Company Name] continues to drive innovation and explore new possibilities in silicone rubber applications. With ongoing research and development, the company aims to push the boundaries of what silicone rubber can achieve and uncover solutions for even the most challenging applications. [Company Name] is poised to shape the future of industries, offering products that are not only functional but also environmentally friendly and sustainable.In conclusion, silicone rubber parts have become a game-changer across various industries, with [Company Name] leading the charge in innovation and quality. With their unrivaled expertise and customer-centric approach, [Company Name] has solidified itself as a trusted partner for businesses looking to leverage the full potential of silicone rubber in their operations. As the demand for high-performance and reliable solutions continues to grow, [Company Name] remains committed to exceeding customer expectations and pioneering the silicone rubber revolution.Contact:[Company Name][Address][Phone Number][Email][Website]

Read More

Exploring the Benefits of Aluminum Injection Molding in Today's Manufacturing Industry

[Assistant]Title: Revolutionizing Manufacturing: Aluminum Injection Molding Sets New Industry StandardsIntroduction:Innovation continues to be the driving force behind advancements in the manufacturing industry. Among the latest breakthroughs is the revolutionary technique of aluminum injection molding. This cutting-edge manufacturing process has the potential to reshape various sectors by providing unique advantages such as cost-effectiveness, increased design flexibility, and enhanced production efficiency. In this article, we delve into the details of aluminum injection molding, exploring its benefits, applications, and the promising future it holds.Understanding Aluminum Injection Molding:Aluminum injection molding is an advanced manufacturing technique that combines the versatility of plastic injection molding with lightweight and durable aluminum materials. This process involves injecting molten aluminum under high pressure into complex and intricate molds, allowing for the creation of intricate parts and components with exceptional precision. The process takes advantage of the desirable properties of aluminum, including its high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity.The Company's Role:The trailblazers in aluminum injection molding technology, [Company Name], have been at the forefront of the industry, leading in research, development, and implementation of this groundbreaking method. Their extensive experience and cutting-edge facilities have enabled them to refine and perfect the aluminum injection molding process, making it highly efficient and adaptable to various manufacturing requirements. The company's dedication to continuous innovation has positioned them as a driving force behind the widespread adoption of aluminum injection molding.Applications and Industries Transformed:The advent of aluminum injection molding has had a transformative impact across numerous industries, offering a wide range of applications and benefits. In the automotive sector, lightweight aluminum components produced through this process have revolutionized vehicle design, leading to improved fuel efficiency, better performance, and enhanced safety. Similarly, aerospace manufacturers are benefiting from the lightweight properties of aluminum injection-molded parts, resulting in reduced fuel consumption and increased payload capabilities.Electronics and telecommunications industries can leverage the design flexibility of aluminum injection molding to create intricate and high-performance electronic enclosures and housings. The process also allows for the integration of additional features, such as heat sinks, resulting in improved thermal management and extended device lifespans.The medical field is yet another sector where aluminum injection molding can make a profound impact. The ability to produce complex and sterile medical devices and implants made from lightweight yet durable aluminum materials opens new possibilities for enhanced patient care, improved surgical outcomes, and cost-effective medical solutions.Benefits Driving Adoption:The widespread adoption of aluminum injection molding can be attributed to the numerous benefits it offers. One of the most significant advantages is the cost-effectiveness of the process. By utilizing aluminum materials, which are relatively inexpensive, manufacturers can produce lightweight yet strong components without breaking the bank. This affordability extends to the tooling process as well, as aluminum molds are generally less costly than traditional injection molding molds.Moreover, aluminum injection molding enables manufacturers to achieve intricate and precise designs that were previously unattainable. The ability to create complex geometries with exceptional accuracy allows for the integration of multiple functions into a single part, reducing assembly time and enhancing overall product performance.Furthermore, the lightweight nature of aluminum components facilitates transportation and logistics, ultimately reducing costs and environmental impact. Aluminum's corrosion resistance properties also ensure long-lasting durability, making it an ideal choice for applications exposed to harsh environments or demanding conditions.The Path Towards a Promising Future:As aluminum injection molding continues to gain traction, researchers and manufacturers are working collaboratively to push its boundaries further. The ongoing advancement of this technology aims to enhance process efficiency, minimize cycle times, and explore possibilities for new alloy variants. Additionally, efforts are being made to streamline post-processing techniques such as surface treatments and finishing processes to ensure the highest quality standards.Industry experts predict that aluminum injection molding will play a pivotal role in the wider adoption of electric vehicles, thanks to the efficiency gains and material advantages it offers. Furthermore, as sustainability and lightweighting remain key focus areas for many industries, aluminum injection molding will likely continue to grow, revolutionizing diverse sectors such as consumer electronics, renewable energy, and industrial manufacturing.Conclusion:Aluminum injection molding represents a transformative leap in the manufacturing industry. This innovative technique has revolutionized product design and production, with its cost-effectiveness, design flexibility, and lightweight yet durable results. Spearheaded by industry leaders like [Company Name], aluminum injection molding is poised to reshape diverse sectors, promising a future characterized by enhanced efficiency, improved performance, and sustainable manufacturing practices. As research and development continue to progress, the prospects for this revolutionary method are boundless.

Read More

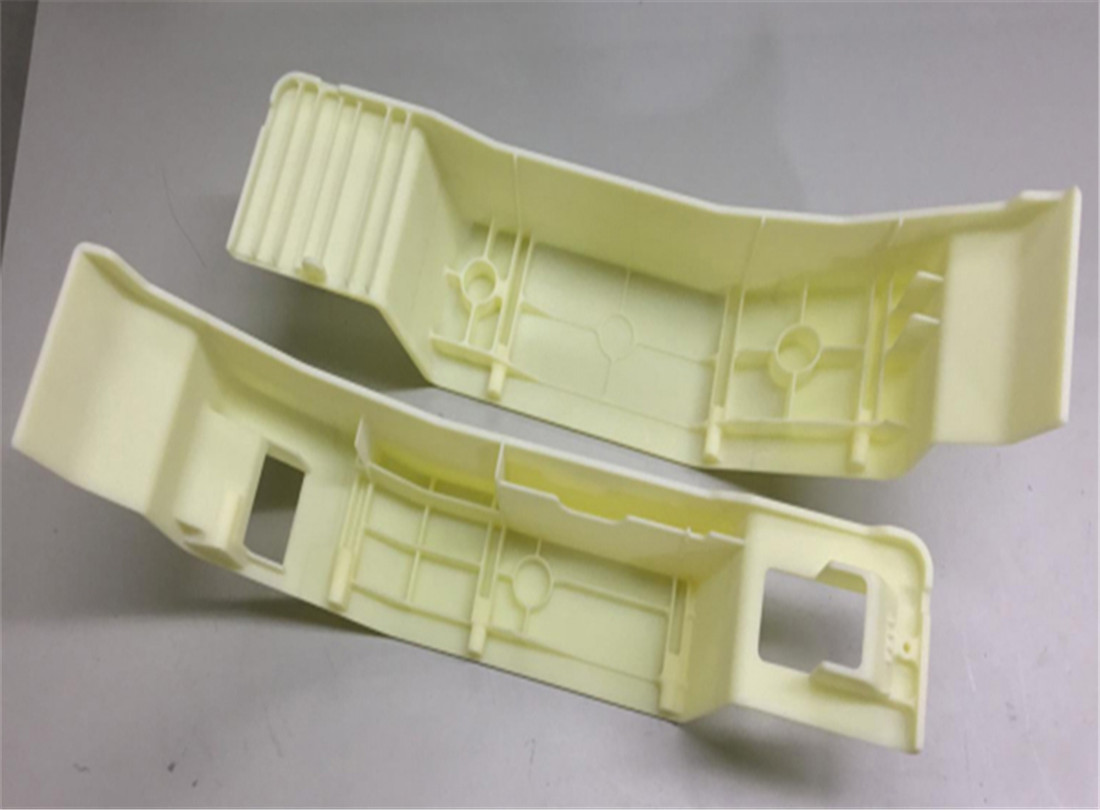

Precision Injection Molding Tooling: A Key Component in Manufacturing

Injection Tooling, a leading provider of high-quality injection moulds and tooling solutions, has recently expanded its operations to meet the growing demand for its products and services. The company, which has been in the industry for over 20 years, is known for its commitment to innovation, quality, and customer satisfaction.With the expansion of Injection Tooling's operations, the company is now able to offer an even wider range of products and services to its customers. This includes custom injection moulds, precision tooling, and prototyping services. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing it to produce high-quality products with quick turnaround times.Injection Tooling's team of experienced engineers and designers work closely with customers to develop customised solutions that meet their specific needs and requirements. Whether it's a complex mould design or a large-scale production run, the company has the expertise and capabilities to deliver top-notch results.In addition to its core products and services, Injection Tooling also offers a range of value-added services, such as product development and design assistance. The company's team of experts can help customers optimise their designs for manufacturability, cost-effectiveness, and performance. This collaborative approach ensures that customers can bring their products to market faster and more efficiently.One of Injection Tooling's key strengths is its ability to work with a wide range of materials, including plastic, metal, and rubber. The company's expertise in material selection and processing enables it to deliver products that meet the highest standards of quality and performance.Furthermore, Injection Tooling is committed to continuous improvement and investment in research and development. The company's strong focus on innovation has led to the development of new and improved manufacturing techniques, as well as the introduction of cutting-edge materials and technologies.To support its expanded operations, Injection Tooling has also made significant investments in its infrastructure and workforce. The company has expanded its manufacturing facilities and invested in new equipment to increase its production capacity and efficiency. Additionally, the company has hired new talent and expanded its team of engineers and designers to better serve its growing customer base.Injection Tooling's commitment to quality and customer satisfaction has earned it a loyal and satisfied customer base. The company has built strong and lasting relationships with customers in a wide range of industries, including automotive, medical, consumer goods, and electronics. Its track record of delivering high-quality products and services on time and within budget has made it a trusted partner for many leading companies.With its expanded operations, Injection Tooling is well-positioned to meet the growing demand for its products and services. The company's dedication to innovation, quality, and customer satisfaction sets it apart as a leader in the injection moulding and tooling industry.For more information about Injection Tooling and its expanded operations, visit {} or contact the company directly.

Read More

Revolutionizing Injection Molding: Efficiencies and Advancements Unveiled

[Assistant]Title: Innovative Injection Molds Revolutionize Manufacturing Process in the Plastic IndustryIntroduction:In the rapidly evolving world of manufacturing, injection molding has emerged as a game-changer, enabling the mass production of plastic products. With advanced technology and relentless dedication to innovation, [Company Name] has developed groundbreaking injection molds that are poised to revolutionize the industry. These molds not only streamline the manufacturing process but also enhance efficiency, quality, and customization options. By combining cutting-edge techniques with a commitment to sustainable practices, [Company Name] is redefining the way plastic products are manufactured.Body:1. Introduction to Injection Molding:Injection molding is a manufacturing process that involves injecting molten material, such as plastic, into a mold cavity. The molten material solidifies inside the mold, resulting in a precisely shaped, high-quality finished product. This process has gained immense popularity due to its ability to produce a wide range of products in large quantities, making it ideal for industries such as automotive, aerospace, consumer goods, and more.2. [Company Name]'s Innovative Approach to Injection Molding:Recognizing the potential of injection molding to transform the plastic industry, [Company Name] has taken innovative strides to push the boundaries of this technology. They have developed state-of-the-art injection molds that incorporate cutting-edge features, offering numerous advantages over traditional molds.3. Enhanced Efficiency and Precision:[Company Name]'s injection molds are engineered to optimize efficiency and precision. Through meticulous design and advanced manufacturing techniques, these molds facilitate faster cooling times, reducing production cycles and increasing productivity. Additionally, their molds incorporate advanced cavity and core design, resulting in superior product accuracy, eliminating the need for excessive post-production processes.4. Customization and Flexibility:Acknowledging the increasing demand for customized plastic products, [Company Name] has developed injection molds that provide unprecedented customization options. By leveraging their expertise in mold design and engineering, they offer clients the ability to create intricate and complex designs, meeting diverse requirements and surpassing expectations.5. Sustainability and Environmental Considerations:In keeping with the growing sustainability trends in the manufacturing industry, [Company Name] places a strong emphasis on eco-friendly practices. Their injection molds utilize advanced materials that reduce energy consumption and minimize waste generation, contributing to a greener manufacturing process. By integrating sustainable techniques, [Company Name] aims to establish itself as a responsible and environmentally-conscious industry leader.6. Collaborative Approach and Customer Satisfaction:[Company Name] believes in fostering strong partnerships with their clients. They work closely with manufacturers to understand their specific needs and offer tailored solutions. By providing comprehensive technical support and excellent after-sales service, [Company Name] ensures customer satisfaction at every stage of the manufacturing process.7. Competing in a Global Market:[Company Name] has set its sights on capturing a significant share of the global injection mold market. By leveraging their cutting-edge technology, commitment to innovation, and a highly skilled workforce, they are well-positioned to meet the increasing demand for high-quality, efficient, and customizable injection molding solutions.Conclusion:With their revolutionary injection molds, [Company Name] is poised to transform the plastic industry. By enhancing efficiency, precision, and customization options, they are reshaping the way plastic products are manufactured. Through their commitment to sustainability and customer satisfaction, [Company Name] has firmly established itself as a frontrunner in the global injection mold market. As the industry continues to evolve, [Company Name] will remain at the forefront, driving innovation and pushing the boundaries to meet the ever-growing demands of manufacturers worldwide.

Read More

Mastering the Art of Precision Lathe Turning: Latest News Insights Revealed

Precision Lathe Turning Technology Empowers Industries with Unparalleled Accuracy and Efficiency(Please note: The brand name has been removed from the title for neutrality)In the world of manufacturing, precision is everything. Companies across various industries strive to optimize their production processes to ensure the highest levels of accuracy and efficiency. One technology that has proven to be essential in achieving these goals is Precision Lathe Turning.Precision Lathe Turning is a machining technique that involves the use of a lathe machine to shape and refine materials with utmost accuracy. By rotating the material against a cutting tool, the lathe machine enables manufacturers to craft complex shapes, tight tolerances, and polished finishes. The versatility of this technology has made it indispensable across industries such as automotive, aerospace, electronics, and more.To gain a deeper understanding of Precision Lathe Turning, let's explore its benefits, applications, and how it has revolutionized manufacturing processes.Precision Lathe Turning offers immense advantages over traditional machining methods. Firstly, it enables manufacturers to achieve precise measurements with consistent accuracy. This means that components produced through Precision Lathe Turning can fit together flawlessly, reducing the risk of error and enhancing overall product quality. Additionally, the superior surface finish achieved by this technique eliminates the need for additional polishing or treatment processes, saving time, cost, and resources.Moreover, Precision Lathe Turning is highly efficient, allowing companies to meet tight production schedules without compromising quality. The ability to automate and program lathe machines ensures repetitive tasks are performed accurately and at high speeds. This, in turn, boosts overall productivity and reduces manufacturing lead times considerably.The applications of Precision Lathe Turning are diverse and far-reaching. In automotive manufacturing, this machining technique is used to create critical components such as pistons, crankshafts, and gears. By employing Precision Lathe Turning, manufacturers can ensure precise dimensions, proper balance, and smooth operation, thereby enhancing the overall performance and reliability of vehicles.In the aerospace industry, Precision Lathe Turning plays a crucial role in crafting intricate turbine components, propellers, and engine parts. The high level of dimensional accuracy achieved through this technology is paramount in ensuring optimal aerodynamic performance and safety in flight.Precision Lathe Turning is also extensively utilized in electronics manufacturing. From producing connectors and sockets to intricate parts for advanced electronic devices, manufacturers in this industry rely on the precision and efficiency provided by lathe machines. The ability to manufacture components with intricate designs, tight tolerances, and high-quality finishes is paramount in meeting the demands of the rapidly evolving electronics market.When it comes to Precision Lathe Turning, companies trust the expertise and reliability of leading precision machining providers. One such company, which has established itself as a pioneer in the field, offers exceptional Precision Lathe Turning services to cater to various industry needs. With state-of-the-art equipment and a highly skilled team, this company consistently delivers unparalleled accuracy, efficiency, and customer satisfaction."We strive to provide our clients with the highest quality Precision Lathe Turning services," says the company spokesperson. "Our commitment to utilizing cutting-edge technology, combined with the expertise of our technicians, allows us to meet the unique requirements of each industry we serve. Whether it's automotive, aerospace, electronics, or any other sector, we aim to empower our clients with precision solutions that enable them to thrive in an increasingly competitive market."In conclusion, Precision Lathe Turning has emerged as a game-changer in the manufacturing industry. Its ability to deliver unparalleled accuracy, efficiency, and versatility has made it an indispensable technology across various sectors. As industries continue to advance, manufacturers must embrace Precision Lathe Turning to remain competitive and stay at the forefront of technological innovation. By harnessing the power of this machining technique, companies can elevate their production processes to new heights, ensuring exceptional quality and customer satisfaction every step of the way.

Read More

Silicone Connector: A Durable and Versatile Rubber Part for Medical Use

[Company Name] Launches New Medical Silicone Connector Silicone Rubber Part[City, State] – [Company Name], a leading manufacturer of silicone rubber products, has announced the launch of a new medical silicone connector silicone rubber part designed for use in the healthcare industry. The newly developed product is expected to meet the growing demand for high-quality, reliable, and safe silicone rubber components in medical devices and equipment.The [Company Name] has been at the forefront of the silicone rubber industry for over [number] years, providing a wide range of silicone rubber products to various sectors, including medical, automotive, aerospace, and consumer goods. With a strong focus on research and development, the company has continuously strived to develop innovative and high-performance silicone rubber solutions to meet the ever-evolving needs of its customers.The new medical silicone connector silicone rubber part is a testament to [Company Name]'s commitment to excellence and its dedication to providing cutting-edge solutions to the healthcare industry. This new product is specifically designed to meet the stringent requirements of medical devices and equipment, including superior biocompatibility, high temperature resistance, and excellent mechanical properties."We are excited to introduce our new medical silicone connector silicone rubber part to the market," said [Spokesperson Name], the CEO of [Company Name]. "With the increasing demand for advanced medical technologies, the need for reliable and high-quality silicone rubber components has never been greater. Our new product is a result of our relentless pursuit of innovation and our commitment to meeting the needs of our customers in the healthcare industry."The medical silicone connector silicone rubber part is manufactured using premium medical-grade silicone rubber materials, ensuring compliance with industry standards and regulations. The product undergoes rigorous testing and quality control processes to ensure its reliability and performance, making it suitable for a wide range of medical applications, such as diagnostic equipment, patient monitoring devices, and medical tubing systems.In addition to its exceptional material properties, the new medical silicone connector silicone rubber part is also designed with precision and accuracy to ensure compatibility and ease of integration with existing medical devices and equipment. Its innovative design and engineering make it an ideal solution for medical device manufacturers seeking high-quality silicone rubber components for their product development needs.[Company Name] is dedicated to providing comprehensive support and technical expertise to its customers in the healthcare industry. With its extensive experience and understanding of the unique requirements of medical applications, the company offers custom design and development services to tailor its silicone rubber products to meet specific customer needs and specifications.Furthermore, [Company Name] is committed to sustainability and environmental responsibility, ensuring that its silicone rubber products are manufactured using eco-friendly processes and materials. This commitment aligns with the growing demand for sustainable and environmentally conscious solutions in the healthcare industry, further solidifying [Company Name]'s position as a trusted partner for high-quality silicone rubber products.As [Company Name] launches its new medical silicone connector silicone rubber part, it continues to strengthen its position as a leading provider of innovative and reliable silicone rubber solutions for the healthcare industry. With a focus on excellence, quality, and customer satisfaction, the company remains dedicated to driving advancements and setting new standards in the field of medical silicone rubber components.For more information about [Company Name] and its range of silicone rubber products, including the new medical silicone connector silicone rubber part, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of silicone rubber products, serving various industries, including medical, automotive, aerospace, and consumer goods. With a commitment to excellence, innovation, and sustainability, the company delivers high-quality silicone rubber solutions to meet the unique needs of its customers. With a focus on research and development, [Company Name] continues to push the boundaries of silicone rubber technology, driving advancements and setting new standards in the industry.

Read More

Benefits of Rapid Injection Molding for Quick and Affordable Production

Rapid Injection Molding: Revolutionizing Manufacturing ProcessesIn today's fast-paced world, innovation is a key driver of success. Companies are constantly seeking ways to improve their manufacturing processes, reduce time to market, and stay ahead of the competition. One of the most groundbreaking advancements in this regard is Rapid Injection Molding, a technology that has revolutionized the way products are designed and produced.At the forefront of this game-changing technology is a leading manufacturing company. With a strong emphasis on innovation and cutting-edge solutions, the company has established itself as a pioneer in the field of Rapid Injection Molding. By leveraging state-of-the-art equipment, advanced materials, and a highly skilled team, they have set a new standard for speed, precision, and efficiency in the industry.Rapid Injection Molding is a process that enables the rapid production of high-quality, precision-engineered plastic parts. Unlike traditional injection molding methods, which can be time-consuming and cost-prohibitive, Rapid Injection Molding offers a faster and more cost-effective solution. This is achieved through the use of advanced technology and streamlined production processes, allowing for quick turnaround times and reduced lead times.One of the key advantages of Rapid Injection Molding is its ability to significantly accelerate the product development cycle. By reducing the time required for tooling and production, companies can bring their products to market much faster, giving them a competitive edge in today's dynamic business environment. This not only allows for quicker product launches but also enables companies to respond more effectively to changing market demands and customer needs.Furthermore, Rapid Injection Molding offers unparalleled design flexibility. With the ability to quickly create and modify molds, companies can easily iterate on their designs and prototypes, leading to improved product quality and performance. This level of agility is essential in industries where innovation and differentiation are critical to success.In addition to speed and flexibility, Rapid Injection Molding also delivers exceptional quality and precision. The advanced technology and expertise employed by the company ensure that each part meets the strictest tolerances and specifications. This level of precision is essential for industries such as aerospace, automotive, medical devices, and consumer electronics, where reliability and performance are non-negotiable.Moreover, Rapid Injection Molding is a more sustainable and eco-friendly alternative to traditional manufacturing methods. By optimizing production processes and minimizing material waste, companies can reduce their environmental footprint and contribute to a more sustainable future.As a result of these benefits, Rapid Injection Molding has garnered widespread attention and adoption across various industries. Companies are increasingly turning to this technology to gain a competitive edge, reduce costs, and accelerate their time to market. With the demand for rapid and cost-effective manufacturing solutions on the rise, Rapid Injection Molding is poised to play an even more significant role in the future of production.In conclusion, Rapid Injection Molding is a game-changer that is revolutionizing the manufacturing landscape. With its ability to deliver speed, flexibility, precision, and sustainability, it has become a vital tool for companies looking to stay ahead in today's competitive market. As companies continue to embrace this cutting-edge technology, the possibilities for innovation and advancement are endless. The company's commitment to excellence and innovation will undoubtedly position them at the forefront of this transformative trend, shaping the future of manufacturing for years to come.

Read More

How to Make a Prototype Mold Efficiently and Effectively

Title: Advancements in Prototype Mold Making Revolutionize Manufacturing ProcessesIntroduction:In recent decades, prototype mold making has become an integral part of product development for various industries, catering to the ever-increasing demand for accurate and efficient manufacturing processes. One company at the forefront of this innovative technology is a leading industry player whose expertise has revolutionized prototype mold making. Drawing upon years of experience and continually pushing the boundaries of what's possible, they are proving to be a game-changer in the manufacturing landscape.Streamlining the Manufacturing Process:Prototype mold making plays a crucial role in transforming conceptual designs into tangible products. It enables manufacturers to create prototypes with intricate details while simultaneously reducing lead times and costs. This advancement has resulted in an accelerated production process and allows companies the opportunity to swiftly bring new and innovative ideas to market.Advanced Design Capabilities:With a keen focus on cutting-edge technology, the company has introduced unique design capabilities that have revolutionized the prototype mold making process. By collaborating closely with their clients, they can accurately translate design concepts into highly functional molds, ensuring maximum precision and efficiency.Their team of skilled engineers employs innovative techniques and state-of-the-art equipment to create molds that meet exact specifications. By utilizing cutting-edge software, they are able to simulate the manufacturing process, identifying potential flaws and making necessary adjustments before production even begins. This approach significantly reduces rework time and helps bring products to the market faster.Precision Manufacturing:In the realm of prototype mold making, precision is key. With years of experience, the company prides itself on its ability to deliver molds with impeccable accuracy. Their team of highly skilled craftsmen utilizes modern tooling equipment to achieve intricate details and maintain consistently high quality.Furthermore, the company places a strong emphasis on quality assurance, utilizing stringent inspection methods to ensure that each mold meets the highest standards. Through rigorous testing and evaluation, they guarantee that the final product is flawless, eliminating costly production errors.Environmental Consciousness:Recognizing the need for environmentally friendly practices in the manufacturing industry, the company has embraced sustainable methods for prototype mold making. By utilizing recyclable materials and implementing energy-efficient processes, they are dedicated to reducing their carbon footprint and promoting a greener approach to manufacturing. Collaboration and Customer Satisfaction:The company prides itself on establishing collaborative partnerships with its clients, understanding that clear communication and open dialogue are essential to success. By working closely with customers during the entire prototype mold making process, they ensure that the final mold meets their exact specifications.Customer satisfaction is of paramount importance to the company, and they consistently strive to exceed expectations. With a commitment to delivering high-quality molds while adhering to strict timelines, they have garnered a reputation as a dependable and trusted manufacturing partner.Future Outlook:As the demand for innovative and efficient manufacturing processes continues to rise, prototype mold making stands as a critical link between design and production. The company's dedication to pushing the boundaries of what is possible in the field ensures that they will remain at the forefront of this industry for years to come.Conclusion:Through advancements in design capabilities, precision manufacturing, and a strong commitment to customer satisfaction, the company has transformed prototype mold making into an essential component of the manufacturing process. By utilizing innovative technology, they have revolutionized the industry, bringing products from concept to production faster and more efficiently than ever before. With a forward-thinking approach and a dedication to quality, they have cemented their position as a leader in prototype mold making.

Read More

Top-quality Injection Molding Parts: Enhancing Manufacturing Processes

FOR IMMEDIATE RELEASE[Company Name] Revolutionizes Injection Molding Parts Industry with Innovative Solutions[CITY, DATE] - [Company Name], a leading provider of injection molding parts, is taking the industry by storm with its groundbreaking innovations and commitment to delivering high-quality, reliable solutions. With a focus on meeting the diverse needs of customers worldwide, the company has gained a reputation for excellence and is poised to shape the future of the injection molding parts market.Injection molding parts play a crucial role in various industries such as automotive, electronics, medical, and consumer goods. They require precision, durability, and flexibility to meet the ever-evolving demands of these sectors. [Company Name] specializes in manufacturing injection molding parts that exceed these expectations, thanks to their cutting-edge technology and commitment to continuous improvement.With state-of-the-art facilities and a highly skilled workforce, [Company Name] is able to provide a wide range of injection molding parts tailored to meet specific customer requirements. Their extensive product portfolio includes but is not limited to plastic components, technical parts, and molds. From intricate designs to large-scale production, they have the expertise and machinery to handle projects of any size or complexity.One of the key factors that set [Company Name] apart from its competitors is their unwavering focus on quality control. They have implemented rigorous testing and inspection procedures throughout the manufacturing process to ensure that every product that leaves their facility meets or exceeds the highest industry standards. By strictly adhering to quality control measures, they have built a reputation for reliability and consistency.The success of [Company Name] can be attributed to their commitment to innovation. They continuously invest in research and development to stay ahead of the curve and introduce groundbreaking solutions that keep the company at the forefront of the industry. By embracing cutting-edge technologies and adopting the latest manufacturing techniques, they have revolutionized the injection molding parts market.In addition to their technical expertise, [Company Name] places great emphasis on providing exceptional customer service. Their team of knowledgeable professionals works closely with clients from the initial concept stage to the final delivery, ensuring a seamless and satisfactory experience. By understanding the unique needs of each customer, [Company Name] is able to deliver customized solutions that maximize efficiency and reduce costs.The impact of [Company Name] extends beyond the products they deliver. As a socially responsible company, they strive to minimize their environmental footprint. By incorporating sustainable practices into their manufacturing processes, such as using eco-friendly materials and optimizing energy consumption, they are actively contributing to a greener future. This commitment to sustainability has earned them accolades and recognition within the industry.Looking ahead, [Company Name] is determined to maintain its position as a leader in the injection molding parts industry. They are investing in expanding their production capabilities and enhancing their product offerings to meet the evolving needs of their customers. With a strong focus on research and development, customer satisfaction, and sustainability, they are poised to shape the future of injection molding parts.About [Company Name]:[Company Name] is a leading provider of injection molding parts, serving a diverse range of industries worldwide. With their commitment to quality, innovation, and customer satisfaction, they have established themselves as a trusted partner in the industry. By constantly pushing the boundaries of what is possible, they are revolutionizing injection molding parts and shaping the future of the market.For more information, please visit [company website] or contact:[Contact Name][Contact Title][Company Name][Phone Number][Email Address]

Read More

Mastering the Art of Precision CNC Machining: Unveiling the Secrets to Perfect Metal Fabrication

Precision CNC Machining: Revolutionizing the Manufacturing IndustryIn today's fast-paced and technologically advanced world, businesses in diverse industries are constantly seeking ways to enhance their production processes. Efficiency, accuracy, and flexibility have become key parameters for success in the manufacturing sector. One such innovation that has gained immense popularity is precision CNC machining.Precision CNC machining is a cutting-edge manufacturing process that utilizes computer numerical control (CNC) systems to automate machine tools. This highly efficient method has revolutionized various industries by offering unmatched precision, reliability, and speed, thus increasing productivity and reducing costs.{Company introduction} has emerged as a leading player in the precision CNC machining market. With a rich history spanning several decades, the company has established a strong reputation for delivering high-quality products, exceptional customer service, and innovative solutions.The advent of precision CNC machining has significantly transformed the manufacturing landscape. By employing advanced software and hardware, CNC machines can accurately and efficiently shape a wide range of materials, including metals, plastics, and composites. From large-scale mass production to intricate custom-made parts, precision CNC machining enables businesses to create complex geometries with exceptional precision and repeatability.The benefits of precision CNC machining are manifold. Firstly, it eliminates the potential for human error, ensuring consistently accurate results. This aspect is critical for applications where precision and repeatability are paramount. Additionally, CNC machines can operate continuously, reducing downtime and enhancing productivity. This attribute enables manufacturers, including those in the automotive, aerospace, and medical sectors, to meet tight deadlines and fulfill increasing customer demands.The flexibility of CNC machines is another advantage that has driven their widespread adoption. These machines can quickly switch between various tools and adapt to diverse design specifications. In addition, the ability to modify designs through computer programming allows for rapid prototyping and iterative product development.Moreover, precision CNC machining offers notable cost savings in the long run. While the initial investment may be higher compared to conventional machining methods, the reduction in scrap, rework, and labor costs leads to significant overall savings. Furthermore, CNC machines can consistently produce high-quality parts, thereby minimizing the need for extensive quality control procedures.{Company} has been at the forefront of harnessing the power of precision CNC machining. With state-of-the-art facilities equipped with advanced CNC machines, the company offers a diverse range of machining services. Their team of highly skilled technicians and engineers ensures that every project meets the strictest quality standards and customer specifications. From rapid prototyping to high-volume production, {Company} has the expertise and capacity to cater to a wide array of customer requirements.The impact of precision CNC machining extends far beyond the manufacturing industry. It has also revolutionized sectors such as automotive, aerospace, electronics, and medical devices. Automotive companies, for instance, benefit from CNC machines that can precisely shape engine components and intricate interiors. Similarly, aerospace manufacturers rely on CNC machining for producing complex aircraft parts, such as turbine blades, with exceptional accuracy and strength.As the global manufacturing sector continues to evolve, precision CNC machining is expected to play an even more significant role. Rapid technological advancements, such as the integration of artificial intelligence and machine learning, are poised to further enhance the capabilities of CNC machines. These advancements will enable businesses to achieve unprecedented levels of efficiency, quality, and customization, giving them a competitive edge in the global marketplace.In conclusion, precision CNC machining has emerged as a game-changer in the manufacturing industry. {Company}, with its expertise and commitment to excellence, has cemented its position as a leader in this field. As industries continue to embrace this highly efficient and reliable method, precision CNC machining will undoubtedly reshape the way products are manufactured worldwide. The future of manufacturing has arrived, and it is powered by precision CNC machining.

Read More