Understanding the Process of Aluminum Die Casting

By:Admin

In recent news, it has been reported that a leading manufacturing company specializing in aluminum die casting has developed a new technique to improve the overall efficiency and quality of their die casting process. The company has invested in state-of-the-art equipment and technology to enhance their production capabilities, allowing them to deliver even more precise and high-quality die-cast components to their customers.

By leveraging advanced simulation and modeling software, the company is able to optimize the design of their molds and casting processes, resulting in improved part quality and reduced cycle times. This investment in cutting-edge technology has allowed them to stay at the forefront of the industry and meet the increasing demand for complex and lightweight die-cast parts.

With a strong focus on innovation and continuous improvement, the company is committed to providing the highest level of quality and performance in their die-cast products. By integrating the latest advancements in aluminum die casting technology, they are able to offer their customers a competitive edge in their respective markets.

The company's dedication to excellence extends beyond their manufacturing capabilities, as they also prioritize sustainability and environmental responsibility in their operations. They have implemented various initiatives to minimize waste and reduce their overall environmental impact, ensuring that their die casting processes are not only efficient and reliable, but also eco-friendly.

Furthermore, the company places a strong emphasis on quality control and customer satisfaction, adhering to strict standards and certifications to uphold the integrity of their products. They have a rigorous testing and inspection process in place to ensure that every die-cast component meets the highest standards of performance and reliability.

With a proven track record of delivering top-tier aluminum die-cast parts to a diverse range of industries, the company has established itself as a trusted partner for businesses seeking superior manufacturing solutions. Their ability to adapt to the evolving needs of their customers and the industry as a whole has solidified their position as a leader in the aluminum die casting sector.

As they continue to push the boundaries of what is possible with aluminum die casting, the company remains committed to driving innovation and exceeding customer expectations. With a forward-thinking approach and a dedication to excellence, they are well-positioned to remain at the forefront of the industry for years to come.

In conclusion, aluminum die casting is a highly versatile and efficient manufacturing process that enables the production of intricate and high-quality components. By investing in cutting-edge technology and prioritizing innovation, a leading manufacturing company has enhanced their capabilities in aluminum die casting, cementing their position as a top-tier provider of high-performance die-cast parts. With a focus on quality, sustainability, and customer satisfaction, the company is well-equipped to meet the demands of a constantly evolving market and maintain their leadership in the industry.

Company News & Blog

Achieve Smooth and Precise Cavity Insert Injection Molding with Advanced Technology

Cavity Insert Injection Molding, a game-changing technology in the field of plastic manufacturing, has become a key focus area for many companies aiming to enhance production efficiency and product quality. One such company at the forefront of this industry trend is {}. As a leading manufacturer in the plastic injection molding industry, {} has been making significant advancements in the development and implementation of cavity insert injection molding technology. This innovative manufacturing process allows for greater precision, efficiency, and flexibility in the production of complex plastic components.Cavity insert injection molding works by utilizing specialized molds with removable inserts that can be easily replaced or modified to accommodate different features or designs within the same mold. This flexibility allows for the production of intricate and multi-functional plastic parts with varying specifications, all within a single manufacturing cycle.The advantages of cavity insert injection molding are numerous. By using this technology, manufacturers can significantly reduce production time, labor costs, and material waste, resulting in a more sustainable and cost-effective manufacturing process. Additionally, the ability to create intricate designs and complex geometries in a single mold offers unprecedented design freedom and product customization options.Moreover, cavity insert injection molding enables the production of high-quality plastic components with tight tolerances and superior surface finishes. This is particularly important for industries such as automotive, medical, and electronics, where precision and consistency are critical for the performance and functionality of the end products.{} has fully embraced this cutting-edge technology, integrating cavity insert injection molding into its state-of-the-art manufacturing facilities. With a team of experienced engineers and technicians, the company has perfected the art of using cavity insert injection molding to meet the unique needs and requirements of its diverse clientele.In addition to the technology itself, {}. has also developed proprietary processes and quality control measures to ensure the highest standards of product excellence and customer satisfaction. By leveraging cavity insert injection molding, the company has been able to produce a wide range of plastic components that not only meet but exceed industry standards.One of the key success factors for {}. is its commitment to continuous improvement and innovation. The company actively invests in research and development to further enhance its cavity insert injection molding capabilities, staying ahead of the curve in the ever-evolving plastic manufacturing landscape.Furthermore, {}. places a strong emphasis on sustainability and environmental responsibility. By optimizing its manufacturing processes with cavity insert injection molding, the company has been able to minimize material waste and energy consumption, contributing to a greener and more sustainable future for the industry.Looking ahead, the future for cavity insert injection molding looks promising, with its potential applications expanding across various industries and sectors. As a pioneer in this field, {}. is well-positioned to lead the way in harnessing the full potential of this transformative technology, driving innovation and excellence in the plastic injection molding industry.In conclusion, cavity insert injection molding is revolutionizing the way plastic components are manufactured, offering unprecedented flexibility, precision, and efficiency. By harnessing this technology, companies like {} are transforming the industry landscape, setting new standards for quality, sustainability, and innovation. As cavity insert injection molding continues to gain momentum, the possibilities for creating high-performance and custom-designed plastic parts are virtually limitless.

Durable Rubber Gasket for Glass: A Complete Guide

[Company Name] Introduces New Rubber Gasket for Glass, Promising Enhanced Protection and Durability[Company Name], a leading manufacturer of industrial sealing solutions, has recently introduced a new rubber gasket specifically designed for glass applications. This innovative product promises to provide enhanced protection and durability for a wide range of glass installations, catering to the needs of various industries including automotive, construction, and manufacturing.The new rubber gasket has been developed using [Company Name]'s cutting-edge technology and expertise in material science. With a focus on delivering superior performance and longevity, the gasket is precision-engineered to withstand the challenges of glass installations in diverse applications.One of the key features of the new rubber gasket is its advanced sealing properties. The gasket is designed to create a secure and tight seal around glass edges, preventing any moisture or debris from entering the gaps. This not only helps to maintain the integrity of the glass installation but also contributes to a longer lifespan of the overall structure.In addition, the rubber gasket offers excellent resistance to environmental factors such as extreme temperatures, UV exposure, and harsh chemicals. This makes it an ideal choice for outdoor as well as indoor glass applications, ensuring that the glass remains protected and intact even in challenging environments.Furthermore, [Company Name] has incorporated innovative design elements into the rubber gasket to facilitate easy installation and maintenance. The gasket is flexible and adaptable, allowing for seamless fitting onto various shapes and sizes of glass. This flexibility not only simplifies the installation process but also minimizes the need for frequent adjustments or replacements, thereby reducing maintenance costs for end users.The introduction of this new rubber gasket is aligned with [Company Name]'s commitment to providing high-quality sealing solutions that meet the evolving needs of its customers. With a proven track record of delivering innovative products and exceptional service, the company has established itself as a trusted partner for businesses across diverse industries.Speaking about the launch of the new rubber gasket, [Name], [Title] of [Company Name], said, "We are excited to introduce this advanced rubber gasket for glass, which reflects our dedication to delivering reliable and efficient sealing solutions. Our team has invested significant time and resources in research and development to ensure that this product meets the highest standards of performance and quality. We believe that this gasket will offer significant value to our customers by enhancing the durability and protection of their glass installations."In response to the introduction of the new rubber gasket, customers and industry experts have expressed positive anticipation for its potential benefits. Many have recognized the need for a high-performance sealing solution for glass and have welcomed [Company Name]'s initiative to address this demand with its innovative product.As the market for glass continues to expand across various sectors, the availability of a dependable rubber gasket holds significant importance for ensuring the longevity and reliability of glass installations. With its latest offering, [Company Name] aims to set a new standard for sealing solutions in the glass industry, providing customers with a trusted and cost-effective solution for their diverse applications.

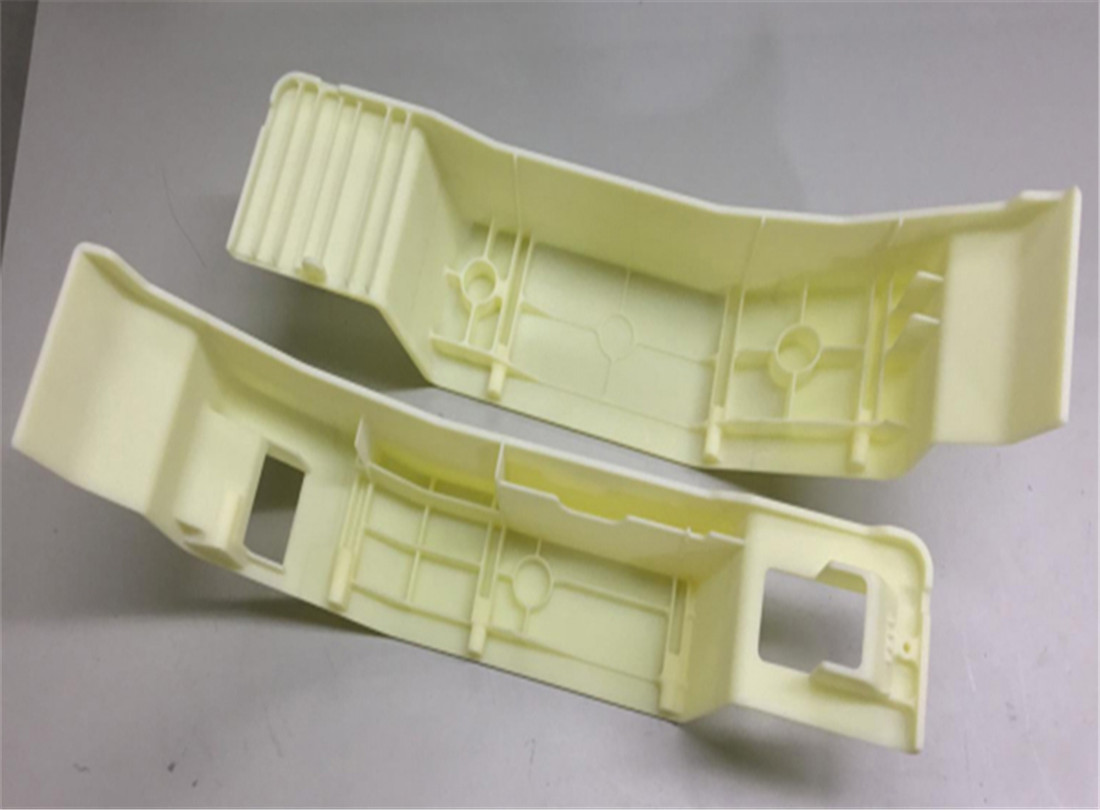

Innovative Rapid Prototyping Techniques Revolutionize Mechanical Engineering

Rapid Prototyping Advancements in Mechanical Engineering: {} Leading the WayIn the world of mechanical engineering, rapid prototyping is a game-changer. With the ability to quickly and cost-effectively produce prototypes and test designs, rapid prototyping has revolutionized the product development process. And at the forefront of this innovation is {}.{} is a leading provider of advanced manufacturing solutions, specializing in rapid prototyping and additive manufacturing technologies. With a strong commitment to delivering high-quality and accurate prototypes, {} has become a trusted partner for companies across various industries.One of the key factors that set {} apart is its dedication to staying ahead of the curve when it comes to advancements in mechanical engineering. The company's team of engineers and researchers are constantly pushing the boundaries of what is possible with rapid prototyping technology. By staying at the forefront of the latest developments in the field, {} is able to provide its clients with cutting-edge solutions that meet their specific needs and requirements.One of the most recent advancements in rapid prototyping is the development of new materials that offer improved mechanical properties and enhanced performance. {} has been at the forefront of integrating these new materials into its prototyping processes, allowing its clients to benefit from the latest innovations in the field. This has been particularly beneficial for companies in industries such as aerospace, automotive, and medical devices, where the demand for high-performance materials is critical.Another area of rapid prototyping that {} has been leading in is the development of more advanced and efficient prototyping processes. By leveraging the latest technologies and manufacturing techniques, {} has been able to significantly reduce production time and cost for its clients while maintaining the highest levels of quality and accuracy. This has allowed companies to accelerate their product development cycles and bring their designs to market faster than ever before.In addition to its technical expertise, {} also prides itself on providing outstanding customer service and support. The company's team of experts works closely with its clients to understand their unique needs and challenges, and develop tailored prototyping solutions that address these requirements. With a deep understanding of the industries it serves, {} is able to provide valuable insights and recommendations that help its clients achieve their goals more effectively.With its comprehensive capabilities and dedication to innovation, {} has solidified its position as a leader in rapid prototyping mechanical engineering. The company's commitment to pushing the boundaries of what is possible with rapid prototyping technology has set it apart from its competitors and positioned it as a go-to partner for companies looking to develop high-quality prototypes and bring their designs to market faster.Looking ahead, {} is poised to continue leading the way in rapid prototyping mechanical engineering, with a focus on further advancements in materials, processes, and technologies. By staying at the forefront of innovation, the company is well-positioned to help its clients succeed in an increasingly competitive and fast-paced market.In conclusion, the future of rapid prototyping mechanical engineering looks bright, and {} is at the forefront of this exciting evolution. With its dedication to innovation, technical expertise, and commitment to customer satisfaction, {} is leading the way in delivering cutting-edge rapid prototyping solutions that empower companies to bring their designs to life faster and more efficiently than ever before.

High Precision Machined Components: A Guide to Precision Manufacturing

high precision machined componentsToday, the demand for high precision machined components is greater than ever before, as industries such as aerospace, automotive, medical, and electronics continue to require increasingly precise and reliable parts. These components play a vital role in ensuring the performance and safety of a wide range of products and machinery, making their production and engineering a critical aspect of modern manufacturing.One company that has been at the forefront of producing high precision machined components is {}. Founded in {}, {} has established itself as a leading provider of precision engineering solutions for a wide range of industries. Specializing in the production of complex and tight-tolerance components, {} has earned a reputation for delivering exceptional quality and reliability in every part they manufacture.The company’s state-of-the-art facilities and advanced machining technologies allow them to produce a diverse range of components with the highest level of precision and accuracy. From intricate medical device parts to complex aerospace components, {} has the expertise and capabilities to meet the most demanding requirements with ease.{}’s team of highly skilled engineers and machinists are dedicated to pushing the boundaries of precision engineering, constantly seeking new ways to enhance their capabilities and improve their processes. This commitment to innovation and continuous improvement has enabled {} to stay ahead of the competition and deliver cutting-edge solutions to their customers.In addition to their technical expertise, {} is also known for their unwavering commitment to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, ensuring that every component they produce meets the highest standards of quality and performance. With a focus on building long-term relationships, {} strives to be a trusted partner to their customers, providing reliable and cost-effective solutions that add value to their businesses.As the demand for high precision machined components continues to grow, {} remains dedicated to staying at the forefront of the industry, investing in new technologies and expanding their capabilities to meet the evolving needs of their customers. With a strong focus on quality, precision, and customer satisfaction, {} is well-positioned to maintain its leadership in the market and continue to be a trusted partner for precision engineering solutions.In conclusion, {}’s commitment to excellence and innovation has positioned them as a leading provider of high precision machined components. With a focus on quality, reliability, and customer satisfaction, {} continues to set the standard for precision engineering solutions, delivering exceptional components that meet the most demanding requirements of a wide range of industries. As the demand for high precision components continues to increase, {} is well-equipped to meet the challenges of the future and remain a trusted partner for precision engineering solutions.

Benefits of Rapid Prototyping And Tooling for Product Development

Rapid Prototyping And Tooling is an essential process in modern manufacturing. It enables companies to quickly and cost-effectively create prototypes and tools, allowing for faster product development and time-to-market. With the help of advanced technologies and a skilled team, the company is leading the way in providing innovative rapid prototyping and tooling solutions for a wide range of industries.As a leading provider of rapid prototyping and tooling services, {Company} has been at the forefront of the industry for many years. The company’s dedication to delivering high-quality, precision-engineered parts and products has made it a trusted partner for businesses looking to accelerate their product development process.With a state-of-the-art facility and a team of experienced engineers and technicians, {Company} is able to offer a wide range of rapid prototyping and tooling services. These include 3D printing, CNC machining, injection molding, and more. By utilizing the latest technologies and techniques, the company is able to produce accurate and reliable prototypes and tools, helping businesses to bring their products to market faster and more efficiently.One of the key advantages of rapid prototyping and tooling is the ability to quickly iterate and test new product designs. This allows companies to make informed decisions about their products, leading to better quality and more successful launches. {Company} understands the importance of this process and works closely with its clients to ensure that their prototypes and tools meet their exact specifications and requirements.In addition to rapid prototyping and tooling services, {Company} also offers design and engineering support. This means that businesses can rely on the company’s expertise to help them develop their product ideas from concept to reality. By combining its advanced manufacturing capabilities with its design and engineering expertise, {Company} is able to provide a comprehensive solution for its clients, helping them to bring their products to market faster and more cost-effectively.{Company} has a proven track record of delivering high-quality rapid prototyping and tooling solutions for a wide range of industries, including automotive, aerospace, medical, consumer goods, and more. Its commitment to quality, precision, and customer satisfaction has earned it a reputation as a trusted partner for businesses looking to innovate and succeed in their respective markets.As the manufacturing industry continues to evolve, the demand for rapid prototyping and tooling services is only expected to grow. {Company} is well-positioned to meet this demand, thanks to its advanced capabilities, skilled team, and unwavering commitment to excellence. With a strong focus on innovation and customer satisfaction, the company is poised to continue leading the way in providing cutting-edge rapid prototyping and tooling solutions for businesses around the world.In conclusion, {Company} is a trusted and innovative provider of rapid prototyping and tooling services. With its state-of-the-art facility, skilled team, and commitment to excellence, the company has established itself as a leader in the industry. Its ability to deliver high-quality, precision-engineered prototypes and tools sets it apart from the competition, making it the ideal partner for businesses looking to accelerate their product development process. With a focus on innovation, customer satisfaction, and continuous improvement, {Company} is well-positioned to meet the evolving needs of the manufacturing industry and help businesses bring their products to market faster and more efficiently.

Benefits of Using Flexible Plastic Molding for Your Business

Flexible Plastic Molding, a leading provider of custom plastic injection molding solutions, has been making waves in the industry with their innovative and flexible approach to manufacturing. With a commitment to quality, service, and reliability, Flexible Plastic Molding has been able to establish themselves as a trusted partner for businesses that require custom plastic parts and components.Founded in 2005, Flexible Plastic Molding has quickly risen to prominence in the industry, thanks to their state-of-the-art facilities, cutting-edge technology, and team of experienced professionals. The company's headquarters, located in the heart of the manufacturing district, houses a large inventory of injection molding machines, robotic assembly systems, and quality control equipment, allowing them to meet the diverse needs of their clients.The company offers a wide range of manufacturing services, including design assistance, mold building, injection molding, assembly, and packaging. This comprehensive approach to manufacturing allows Flexible Plastic Molding to support their clients through every stage of the production process, from initial concept to final product.One of the key differentiators for Flexible Plastic Molding is their ability to work with a variety of materials, including high-temperature thermoplastics, engineering-grade resins, and elastomers. This flexibility allows them to accommodate a wide range of project requirements, from simple consumer goods to complex industrial components.In addition to their injection molding capabilities, Flexible Plastic Molding also provides value-added services such as insert molding, overmolding, and secondary operations. This holistic approach to manufacturing sets them apart from their competitors, as it allows them to deliver fully finished products that are ready for immediate use.The company's commitment to quality is evident in their ISO 9001:2015 certification, which ensures that they adhere to the highest standards of operation and production. This certification, combined with their advanced quality control processes, allows Flexible Plastic Molding to consistently deliver products that meet or exceed their clients' expectations.One of the company's recent success stories involves a partnership with a leading automotive manufacturer. The client approached Flexible Plastic Molding with a complex project that required the production of a series of precision-engineered components for their latest vehicle model. Thanks to their expertise in high-precision molding and their dedication to meeting tight tolerances, Flexible Plastic Molding was able to deliver the components on time and within budget, earning praise from the client for their exceptional quality and service.Looking towards the future, Flexible Plastic Molding is poised for continued growth and success, as they continue to invest in new technologies and expand their capabilities. With a focus on innovation and continuous improvement, the company is well-positioned to meet the evolving needs of their clients and the industry as a whole.In conclusion, Flexible Plastic Molding has established themselves as a go-to partner for businesses in need of custom plastic injection molding solutions. With a strong commitment to quality, service, and reliability, as well as a comprehensive range of manufacturing services and capabilities, the company is well-equipped to take on projects of any size and complexity. As they continue to push the boundaries of what is possible in plastic molding, Flexible Plastic Molding is set to remain a leader in the industry for years to come.

Aluminum CNC Turning Parts for Electroplating Services

Electroplating Aluminum CNC Turning Parts Boosts Company’s Product LineIn the world of manufacturing, precision and quality are paramount. That’s why the team at [Company Name] is proud to announce the addition of a new line of electroplating aluminum CNC turning parts to their already impressive product offerings.Since [Company Name] was founded in [year], our mission has been to provide top-notch manufacturing solutions to our customers. With a focus on innovation and continuous improvement, we have become a trusted partner for a wide range of industries, including automotive, aerospace, and telecommunications.The addition of electroplating aluminum CNC turning parts is a natural progression for [Company Name]. This new line of parts will allow us to further expand our capabilities and better serve the needs of our customers. By leveraging the latest technology and our team’s expertise, we are confident that these parts will meet the high standards that our customers have come to expect.Electroplating aluminum CNC turning parts offer a number of advantages, including improved corrosion resistance, enhanced durability, and a sleek, polished finish. These parts are ideal for applications where aesthetics are important, as well as for projects that require a high level of precision and reliability.At [Company Name], we are committed to providing our customers with the best possible products and services. That’s why we have invested in state-of-the-art equipment and have implemented rigorous quality control measures to ensure that our electroplating aluminum CNC turning parts meet the highest standards.In addition to the superior quality of our products, we also take pride in our ability to provide personalized service and tailored solutions to meet the unique needs of each customer. Whether it’s a small prototype or a large production run, our team is dedicated to delivering exceptional results on time and within budget.As we continue to grow and expand our capabilities, [Company Name] remains dedicated to upholding our core values of integrity, excellence, and customer satisfaction. We believe that the addition of electroplating aluminum CNC turning parts will further solidify our position as a leader in the manufacturing industry and will allow us to continue providing innovative solutions to our valued customers.In conclusion, the team at [Company Name] is thrilled to introduce our new line of electroplating aluminum CNC turning parts. With their superior quality and aesthetic appeal, these parts are sure to enhance our product offerings and provide added value to our customers. We look forward to the opportunity to demonstrate the capabilities of these parts and to partner with our customers on their upcoming projects. Thank you for your continued support and trust in [Company Name] as we strive to exceed your expectations and deliver excellence in manufacturing.

High-Quality Custom Sheet Metal Fabrication Service for Your Needs

Custom Sheet Metal Fabrication Service Offers High-Quality Solutions for Diverse IndustriesIn today's highly competitive industrial environment, companies are constantly striving to find efficient and cost-effective solutions for their manufacturing needs. Custom sheet metal fabrication services play a crucial role in meeting these requirements by providing tailored solutions for a wide range of industries. With the inherent flexibility and durability of sheet metal, businesses can achieve precision and reliability in their manufacturing processes.One such company that has excelled in providing custom sheet metal fabrication services is {}. With years of experience in the industry, they have established themselves as a reliable and trusted partner for businesses looking for high-quality sheet metal solutions.The company's dedication to excellence is evident in their state-of-the-art facilities and a team of skilled craftsmen who are committed to delivering exceptional results. Their comprehensive range of services includes laser cutting, CNC punching, metal forming, welding, and finishing. This diverse set of capabilities allows them to cater to a wide array of requirements and produce intricate and complex sheet metal components with utmost precision.The custom sheet metal fabrication service offered by {} is tailored to meet the specific needs of each client, ensuring that every project is completed to the highest standards. From concept to completion, their team works closely with customers to understand their requirements and provide innovative solutions that effectively address their unique challenges.The company's commitment to quality and client satisfaction is reflected in their stringent quality control processes, ensuring that every product meets the highest industry standards. As a result, businesses can rely on {} to deliver superior sheet metal components that are durable, precise, and reliable.One of the key advantages of custom sheet metal fabrication is its versatility. From automotive and aerospace to electronics and construction, sheet metal components are utilized across a broad spectrum of industries. Through custom fabrication services, businesses can capitalize on the inherent strength and malleability of sheet metal to create components that are tailored to their specific applications.Due to the complexity and precision required in custom sheet metal fabrication, it is crucial for businesses to partner with a reliable and experienced service provider. {}'s track record of success and longstanding reputation in the industry make them a preferred choice for businesses seeking top-notch sheet metal solutions.In addition to their technical capabilities, {} is also dedicated to sustainable and environmentally conscious practices. By optimizing material usage and recycling waste, they minimize their environmental footprint while ensuring cost efficiency for their clients.As the demand for custom sheet metal fabrication continues to grow, companies are increasingly turning to experienced service providers like {} to meet their manufacturing needs. Whether it's prototyping, small-scale production, or large-scale manufacturing, the company's comprehensive services enable businesses to achieve their objectives with utmost precision and efficiency.With a focus on innovation, quality, and customer satisfaction, {} has established itself as a leader in the custom sheet metal fabrication industry. As the company continues to expand its capabilities and offerings, businesses can look forward to even more tailored and reliable sheet metal solutions in the future.

Innovative Functional Prototypes for Product Development

Functional Prototypes Making Manufacturing Process Faster and More EfficientIn the increasingly competitive world of manufacturing, companies are constantly seeking ways to streamline their production processes and bring new products to market faster. One innovative solution that is gaining traction in the industry is the use of functional prototypes. These prototypes are helping companies to test and refine their designs more efficiently, ultimately reducing the time and costs associated with traditional manufacturing processes.One company at the forefront of this trend is {}. As a leading provider of advanced manufacturing solutions, {} has been leveraging the power of functional prototypes to help its clients optimize their product development processes. By combining cutting-edge technology with their extensive expertise in manufacturing, the company has been able to deliver tangible results for its customers.Functional prototypes are physical models of a product that closely resemble the final design and are fully functional. They are created using advanced manufacturing techniques such as 3D printing, CNC machining, and injection molding. These prototypes allow companies to test the functionality, fit, and performance of their designs before committing to full-scale production.The benefits of using functional prototypes are numerous. By allowing companies to identify and address potential design flaws early in the development process, these prototypes help to minimize the risk of costly errors and rework down the line. They also enable companies to get valuable feedback from stakeholders and end-users, leading to improved product quality and customer satisfaction.{} has developed a precise and efficient process for creating functional prototypes. The company's team of skilled engineers and technicians works closely with clients to understand their specific needs and design requirements. Using state-of-the-art technology and advanced materials, {} is able to produce high-quality prototypes that closely mimic the final product's form, fit, and function.One of the key advantages of working with {} is the company's ability to rapidly iterate on prototypes. This means that clients can quickly test different design variations and make adjustments as needed, without having to endure lengthy lead times or incur high costs. This agility is particularly valuable in industries where time-to-market is a critical factor in achieving success.In addition to speeding up the product development process, functional prototypes also play a crucial role in helping companies to secure funding and investment. By presenting potential investors with a physical representation of their product ideas, companies can effectively demonstrate the value and marketability of their innovations. This can be a game-changer for startups and emerging companies looking to secure the resources they need to bring their products to market.The impact of functional prototypes extends beyond the manufacturing sector. Many industries, including automotive, aerospace, consumer electronics, and medical devices, are leveraging the power of advanced prototypes to drive innovation and stay ahead of the competition. As the technology continues to evolve, the potential applications for functional prototypes are only expected to expand.With its commitment to delivering cutting-edge manufacturing solutions, {} is poised to continue playing a key role in driving the adoption of functional prototypes across various industries. By offering a comprehensive range of services, from design assistance to prototype production, the company is well-positioned to help its clients bring their ideas to life in the most efficient and cost-effective manner.As the demand for faster, more efficient manufacturing processes continues to grow, functional prototypes are set to become an essential tool for companies seeking to stay competitive in today's dynamic marketplace. With its expertise and resources in this area, {} is well-equipped to be a valuable partner for companies looking to harness the power of functional prototypes to drive their product development efforts.

Aluminum CNC Turning Parts for Electroplating: A Complete Guide

The electrifyingly innovative process of electroplating aluminum CNC turning parts has taken the manufacturing industry by storm. This cutting-edge procedure, offered by [Company Name], has revolutionized the industry by providing high-quality aluminum components with a protective and decorative finish.[Company Name] has been a leading provider of precision machining and electroplating services for over a decade. Specializing in high-quality aluminum CNC turning parts, the company has continuously pushed the boundaries of innovation and technology to meet the ever-changing needs of its customers.The process of electroplating aluminum CNC turning parts involves the deposition of a thin layer of metal, typically aluminum, onto the surface of a substrate, such as a machined part. This process not only enhances the appearance of the parts but also provides crucial protection against corrosion and wear.With the use of state-of-the-art electroplating equipment and highly skilled technicians, [Company Name] has mastered the art of electroplating aluminum CNC turning parts to exacting standards. The company's commitment to quality and precision has set it apart from its competitors, making it a preferred choice for customers who demand nothing but the best.The benefits of electroplating aluminum CNC turning parts are numerous. In addition to providing a striking finish, the process also improves the part's resistance to wear and tear, thus extending its lifespan. This makes the parts ideal for a wide range of applications, from automotive and aerospace to consumer electronics and industrial machinery.The electroplating process at [Company Name] is carried out with utmost precision, ensuring that the parts meet the strictest quality standards. Each part is meticulously inspected to ensure that it meets the customer's specifications before it is dispatched. This attention to detail has earned [Company Name] a reputation for excellence in the industry.As demand for electroplated aluminum CNC turning parts continues to grow, [Company Name] has invested in expanding its electroplating capabilities. The company has acquired new equipment and facilities to accommodate larger volumes and more diverse product requirements. This expansion has enabled [Company Name] to take on new and challenging projects, further solidifying its position as a leader in the industry.In addition to its electroplating services, [Company Name] also offers a range of other machining and finishing processes to meet the needs of its customers. From CNC milling to anodizing and powder coating, the company provides a comprehensive suite of services to cater to a wide variety of industries.With its unwavering commitment to quality, precision, and customer satisfaction, [Company Name] has positioned itself as a trusted partner for businesses looking for high-quality aluminum CNC turning parts. The company's dedication to innovation and excellence has earned it the loyalty of a loyal customer base and continues to drive its growth and success in the industry.In conclusion, the electroplating of aluminum CNC turning parts offered by [Company Name] is a game-changer in the manufacturing industry. With its impeccable quality, precision, and commitment to customer satisfaction, the company is well-positioned to meet the evolving needs of its customers and continue its success in the industry for years to come.