Turned Brass Components: A Guide to Precision Manufacturing

By:Admin

In the world of manufacturing, precision is key. Every component needs to fit perfectly and perform its function flawlessly. That's why many manufacturers turn to brass precision turned components to ensure the quality and reliability of their products.

Brass precision turned components are a critical part of many industries, including automotive, aerospace, electronics, and medical devices. These components are used in a wide range of applications, including fittings, connectors, valves, and plumbing fixtures. The use of brass in precision turned components offers a number of advantages, including excellent machinability, corrosion resistance, and an attractive appearance.

One company that has been leading the way in the production of brass precision turned components is {}. With over 20 years of experience in the industry, {} has gained a reputation for delivering high-quality, precision-machined components to a wide range of industries around the world.

{} specializes in the production of a wide range of brass precision turned components, including fittings, connectors, adaptors, and valves. The company's state-of-the-art manufacturing facility is equipped with the latest CNC turning machines, allowing them to produce components with tight tolerances and complex geometries. With a focus on precision and quality, {} has become a trusted partner for many leading manufacturers.

One of the key factors that sets {} apart from its competitors is its commitment to quality. The company's manufacturing processes are ISO 9001 certified, ensuring that every component meets the highest standards of quality and reliability. {} also utilizes advanced metrology equipment to perform rigorous quality control checks on every component, ensuring that they meet or exceed customer specifications.

In addition to its commitment to quality, {} is also dedicated to providing exceptional customer service. The company works closely with its customers to understand their specific needs and requirements, and then develops customized solutions to meet those needs. Whether a customer requires a small batch of custom components or a large production run, {} has the capabilities and expertise to deliver.

Another key strength of {} is its ability to work with a wide range of materials. In addition to brass, the company also produces precision turned components in stainless steel, aluminum, and various engineering plastics. This versatility allows {} to serve a diverse range of industries and applications, further solidifying its position as a leader in the precision turned components market.

Looking to the future, {} is constantly investing in new technologies and processes to further improve its capabilities. The company is exploring the use of advanced materials and coatings to enhance the performance and longevity of its components. Additionally, {} is expanding its facilities to accommodate growing demand and to increase its production capacity.

With its unwavering commitment to quality, exceptional customer service, and continuous investment in technology and innovation, {} has positioned itself as a trusted partner for manufacturers in need of brass precision turned components. As the demand for high-quality, reliable components continues to grow, {} is well-equipped to meet the needs of its customers and maintain its leadership in the market.

Company News & Blog

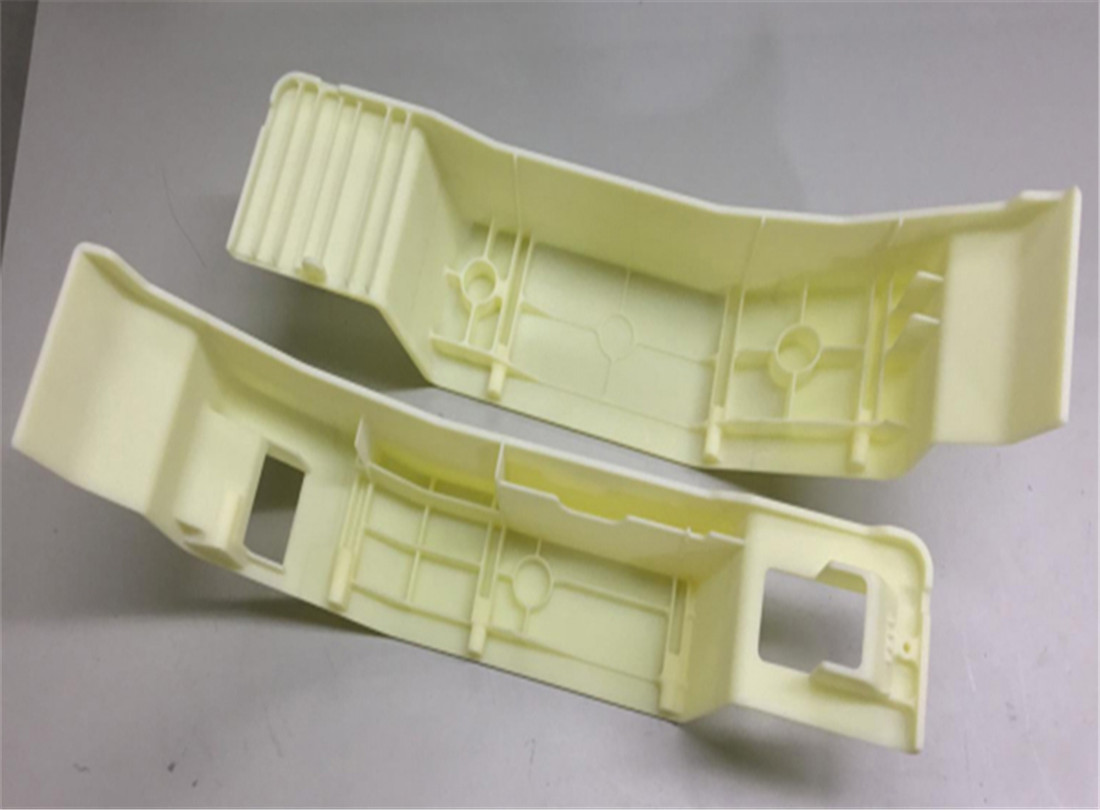

High-Quality Precision Molding: What You Need to Know

Precision Molding, a leading provider of high-quality plastic injection molding solutions, is making waves in the industry with their innovative and state-of-the-art manufacturing processes. With a strong focus on precision, efficiency, and cost-effectiveness, Precision Molding continues to set the benchmark for excellence in the plastic molding industry.Precision Molding has been in the business for over 20 years and has a proven track record of delivering top-notch products to a wide range of industries, including automotive, medical, consumer goods, and electronics. The company prides itself on its ability to consistently meet and exceed the expectations of its clients, thanks to its highly skilled team of engineers, designers, and manufacturing specialists who are dedicated to delivering the highest quality products.One of Precision Molding's key strengths lies in its ability to provide custom molding solutions that are tailored to meet the specific needs of each client. Whether it's a complex automotive component or a simple consumer product, the company's team of experts has the knowledge and expertise to design and manufacture products that meet the highest standards of quality and precision. This level of customization sets Precision Molding apart from its competitors and allows the company to provide unparalleled value to its clients.In addition to its custom molding capabilities, Precision Molding also offers a range of standard products that are designed to meet the needs of clients across various industries. These products are manufactured using the same high standards of quality and precision that the company is known for, ensuring that clients receive reliable and consistent solutions for their plastic molding needs.One of the key factors that sets Precision Molding apart from its competitors is its investment in cutting-edge technology and state-of-the-art manufacturing processes. The company utilizes the latest in injection molding equipment and technology to ensure that every product meets the highest standards of quality and precision. This commitment to staying at the forefront of industry advancements allows Precision Molding to deliver superior products to its clients, while also maintaining a competitive edge in the market.Another important aspect of Precision Molding's business strategy is its commitment to sustainability and environmental responsibility. The company is dedicated to reducing its environmental impact by implementing eco-friendly manufacturing processes and materials. This dedication to sustainability not only benefits the environment but also positions Precision Molding as a responsible and forward-thinking partner for its clients.Looking ahead, Precision Molding plans to continue its growth and expansion in the plastic molding industry, with a focus on developing new and innovative solutions that meet the evolving needs of its clients. The company is committed to maintaining its reputation for excellence and aims to further solidify its position as a leader in the industry.Precision Molding's dedication to precision, efficiency, and quality has made it a trusted partner for clients across a wide range of industries. With its commitment to innovation, technology, and sustainability, the company is well-positioned for continued success and is poised to remain a leader in the plastic molding industry for years to come.

Ultimate Guide to Plastic Injection Mold Making

Plastic Injection Mold Making is a crucial process in the production of various plastic products. It involves the design and creation of molds that are used to shape and form plastic materials into the desired products. This process requires precision and expertise to ensure that the molds are of high quality and can produce consistent and accurate products.One company that has excelled in the field of Plastic Injection Mold Making is {company name}. With over 20 years of experience in the industry, {company name} has established itself as a leading provider of mold making services. The company specializes in creating custom molds for a wide range of industries, including automotive, medical, consumer goods, and more.{company name} takes pride in its ability to deliver high-quality molds that meet the unique requirements of each client. The company has a team of skilled engineers and designers who work closely with clients to understand their specific needs and develop customized solutions. From the initial design concept to the final production, {company name} ensures that every step of the mold making process is carried out with precision and attention to detail.One of the key factors that sets {company name} apart from its competitors is its commitment to innovation and technology. The company invests in state-of-the-art equipment and utilizes the latest software and tools to streamline the mold making process. This not only allows for greater precision and accuracy in mold design, but also enables {company name} to deliver molds in a shorter timeframe, helping clients to bring their products to market faster.In addition to its technical capabilities, {company name} also prides itself on its dedication to quality and customer satisfaction. The company follows strict quality control measures to ensure that every mold meets the highest standards. This includes thorough testing and inspection of the molds to guarantee their performance and durability.Furthermore, {company name} places a strong emphasis on building long-term partnerships with its clients. The company works collaboratively with clients throughout the mold making process, providing regular updates and seeking feedback to ensure that the final product meets their expectations. {company name}’s commitment to customer service and support has earned it a reputation as a reliable and trustworthy partner in the industry.With its extensive experience, technical expertise, and dedication to quality, {company name} has become a go-to source for Plastic Injection Mold Making. The company has successfully delivered custom molds for a wide range of applications, helping clients to bring their innovative products to market.Looking ahead, {company name} remains focused on driving innovation and excellence in Plastic Injection Mold Making. The company continues to invest in new technologies and processes to further enhance its capabilities and deliver even greater value to its clients. With a strong track record of success and a commitment to continuous improvement, {company name} is well-positioned to remain a leader in the field of mold making for years to come.

High Precision Machined Components: A Guide to Precision Manufacturing

high precision machined componentsToday, the demand for high precision machined components is greater than ever before, as industries such as aerospace, automotive, medical, and electronics continue to require increasingly precise and reliable parts. These components play a vital role in ensuring the performance and safety of a wide range of products and machinery, making their production and engineering a critical aspect of modern manufacturing.One company that has been at the forefront of producing high precision machined components is {}. Founded in {}, {} has established itself as a leading provider of precision engineering solutions for a wide range of industries. Specializing in the production of complex and tight-tolerance components, {} has earned a reputation for delivering exceptional quality and reliability in every part they manufacture.The company’s state-of-the-art facilities and advanced machining technologies allow them to produce a diverse range of components with the highest level of precision and accuracy. From intricate medical device parts to complex aerospace components, {} has the expertise and capabilities to meet the most demanding requirements with ease.{}’s team of highly skilled engineers and machinists are dedicated to pushing the boundaries of precision engineering, constantly seeking new ways to enhance their capabilities and improve their processes. This commitment to innovation and continuous improvement has enabled {} to stay ahead of the competition and deliver cutting-edge solutions to their customers.In addition to their technical expertise, {} is also known for their unwavering commitment to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, ensuring that every component they produce meets the highest standards of quality and performance. With a focus on building long-term relationships, {} strives to be a trusted partner to their customers, providing reliable and cost-effective solutions that add value to their businesses.As the demand for high precision machined components continues to grow, {} remains dedicated to staying at the forefront of the industry, investing in new technologies and expanding their capabilities to meet the evolving needs of their customers. With a strong focus on quality, precision, and customer satisfaction, {} is well-positioned to maintain its leadership in the market and continue to be a trusted partner for precision engineering solutions.In conclusion, {}’s commitment to excellence and innovation has positioned them as a leading provider of high precision machined components. With a focus on quality, reliability, and customer satisfaction, {} continues to set the standard for precision engineering solutions, delivering exceptional components that meet the most demanding requirements of a wide range of industries. As the demand for high precision components continues to increase, {} is well-equipped to meet the challenges of the future and remain a trusted partner for precision engineering solutions.

Fast Turnaround Injection Molding: How It Works and Why It's Important

As the demand for fast and high-quality injection molding continues to rise in various industries, many companies are seeking innovative solutions to accommodate this growing need. One such company, (remove brand name), has established a reputation for being a leader in quick turn injection molding, providing efficient and reliable services to its customers.(Supply company introduction details here)Quick turn injection molding has become increasingly essential for businesses looking to streamline their production processes and accelerate the time-to-market for their products. With the ability to produce high-quality parts in a fraction of the time compared to traditional injection molding methods, quick turn injection molding has revolutionized the manufacturing industry.One of the key advantages of quick turn injection molding is the rapid prototyping capabilities it offers. Companies can quickly iterate and test different designs, enabling them to bring new products to market faster than ever before. This agile approach to product development is vital for staying ahead of the competition and meeting the ever-changing demands of consumers.With (remove brand name)'s expertise in quick turn injection molding, they are able to offer their customers a range of materials to choose from, including various engineering-grade resins, thermoplastics, and elastomers. This versatility allows for the production of parts with different properties, such as high heat resistance, impact strength, or flexibility, depending on the specific requirements of the application.In addition to material options, (remove brand name) also utilizes advanced manufacturing technologies to ensure the highest level of precision and quality in their injection molded parts. Their state-of-the-art equipment and processes enable them to produce intricate and complex geometries with tight tolerances, meeting the stringent standards of various industries, including automotive, aerospace, medical, and consumer electronics.Another significant benefit of working with (remove brand name) for quick turn injection molding is their commitment to cost-effectiveness. By minimizing lead times and tooling costs, companies can significantly reduce their overall production expenses, making quick turn injection molding a cost-efficient solution for both low and high-volume manufacturing needs.Furthermore, (remove brand name)'s dedication to customer service and satisfaction sets them apart in the industry. They work closely with their clients from the initial design phase through to production, offering guidance and expertise to ensure that the final injection molded parts meet or exceed expectations.The company's quick turn injection molding services have garnered acclaim from a wide range of industries, earning them a reputation as a trusted and reliable partner for businesses looking to optimize their manufacturing processes and bring their products to market faster.In conclusion, the demand for quick turn injection molding continues to grow, and (remove brand name) is at the forefront of meeting this demand with their unparalleled expertise and state-of-the-art capabilities. With a commitment to quality, efficiency, and customer satisfaction, (remove brand name) has solidified its position as a leading provider of quick turn injection molding services, offering innovative solutions to help businesses thrive in today's competitive market.

Expert Tips for Plastic Injection Mold Making - A Complete Guide

Plastic Injection Mold Making is an essential process in the manufacturing industry, as it allows for the production of high-quality plastic components used in various products. From automotive parts to household appliances, plastic injection molds play a crucial role in the production of everyday items. One company at the forefront of plastic injection mold making is {}. With state-of-the-art facilities and a team of experienced professionals, they have established themselves as a leading provider in the industry.Founded in {}, {} has quickly risen to prominence in the field of plastic injection mold making. The company prides itself on its commitment to quality, innovation, and customer satisfaction. Their team of highly skilled engineers and technicians work tirelessly to ensure that each mold produced meets the highest standards of excellence. With a focus on precision and efficiency, {} has earned a reputation for delivering superior molds that are essential for the manufacturing process.{}'s dedication to innovation is evident in their advanced manufacturing capabilities. Their facilities are equipped with cutting-edge technology and machinery, allowing them to produce molds with intricate designs and complex geometries. Additionally, the company leverages the latest software and simulation tools to optimize the mold making process, resulting in faster production times and cost savings for their clients.In addition to their technical expertise, {} places a strong emphasis on customer collaboration. They work closely with each client to understand their specific needs and requirements, ensuring that the final product meets their exact specifications. Whether it's a prototype mold or a large-scale production run, {} is dedicated to delivering solutions that exceed expectations.Furthermore, {} is committed to sustainability and environmental responsibility in their manufacturing processes. They strive to minimize waste and reduce their carbon footprint by implementing eco-friendly practices and materials. By prioritizing sustainability, {} not only contributes to a cleaner environment but also helps their clients meet their own sustainability goals.With a diverse client base that spans across industries, {} has proven to be a reliable partner for companies seeking high-quality plastic injection molds. From small businesses to multinational corporations, {} has the expertise and capability to meet the unique demands of each client. Their commitment to excellence, combined with their unwavering dedication to customer satisfaction, has solidified their position as a trusted leader in the industry.Looking ahead, {} is poised for continued success and growth in the plastic injection mold making sector. With a focus on innovation, quality, and customer collaboration, they are well-positioned to meet the evolving needs of the manufacturing industry. As the demand for high-quality plastic components continues to rise, {} remains dedicated to delivering exceptional molds that drive the success of their clients.In conclusion, plastic injection mold making is a critical process in the manufacturing industry, and {} has established itself as a premier provider in the field. With their advanced capabilities, commitment to sustainability, and dedication to customer satisfaction, {} sets the standard for excellence in plastic injection mold making. As they continue to innovate and expand their offerings, {} is poised to remain a driving force in the industry for years to come.

High-Quality Spinning Spare Parts Manufacturers in China

China Spinning Spare Parts Manufacturers Deliver High-Quality ProductsChina is known for its manufacturing prowess and is a leader in producing a wide range of industrial products. One industry that has seen significant growth in China is the spinning spare parts sector. With increasing demand for high-quality spinning spare parts, manufacturers in China have stepped up to deliver top-notch products to meet the needs of the global market.One such leading spinning spare parts manufacturer is {}. With a wealth of experience and a commitment to quality, the company has established itself as a trusted name in the industry. Their extensive range of spinning spare parts is highly sought after by textile companies around the world.Established in {}, the company has grown from strength to strength, thanks to its relentless pursuit of excellence and customer satisfaction. Their state-of-the-art manufacturing facilities are equipped with the latest technology and production processes, ensuring that every spinning spare part meets the highest standards of quality and performance.The company's product line includes a diverse range of spinning spare parts, such as spinning cot, rubber cot, aprons, clearer roller, and other accessories for spinning machinery. These parts are crucial for the smooth and efficient operation of spinning machines, and the company's commitment to precision engineering ensures that their products deliver exceptional performance and durability.In addition to their extensive product range, the company also prides itself on its ability to provide customized solutions to meet the unique needs of their clients. Whether it is a specific size, material, or design requirement, their team of experts works closely with customers to develop tailor-made spinning spare parts that exceed expectations.With a strong focus on research and development, the company continually invests in innovation to stay ahead of the curve and anticipate the evolving needs of the spinning industry. This dedication to innovation has enabled them to introduce advanced materials and manufacturing techniques, resulting in spinning spare parts that offer superior reliability and longevity.Furthermore, the company's commitment to sustainability and environmental responsibility is evident in their production processes. They adhere to strict environmental regulations and work towards minimizing their carbon footprint, ensuring that their manufacturing practices are as eco-friendly as possible.By prioritizing quality, innovation, and customer satisfaction, {}. has earned a reputation as a reliable and trusted partner for textile companies worldwide. They have successfully established a strong presence in the global market, with their spinning spare parts being used in spinning mills across Europe, Asia, the Americas, and beyond.As the demand for high-quality spinning spare parts continues to grow, China's spinning spare parts manufacturers are well-positioned to capitalize on this trend. With their proven track record and a commitment to excellence, companies like {} are poised to lead the way in meeting the needs of the global spinning industry.In conclusion, China's spinning spare parts manufacturers are delivering high-quality products that are reshaping the global spinning industry. With their focus on quality, innovation, and customer satisfaction, companies like {} are driving the industry forward and setting new standards for spinning spare parts. As the industry continues to evolve, China's spinning spare parts manufacturers are well-equipped to meet the demands of the market and play a pivotal role in its growth and development.

Discover High-Quality Silicone Parts for Various Applications

Title: Revolutionizing the Industry – Innovative Silicone Parts (brand name removed) Sets New StandardsIntroduction (about 80 words):Silicone Parts, a pioneer in the silicone manufacturing industry, has been making waves with its groundbreaking products that are proving to be game-changers. With years of experience and expertise, the company is committed to delivering silicone parts that are not only high-quality but also technologically advanced, providing value to various industries. Let's explore further how Silicone Parts is revolutionizing the industry with its innovative solutions. Body:1. History and Expertise (about 120 words):Silicone Parts, founded in [year], has grown to become a leading name in the silicone manufacturing sector. Its success can be attributed to its unwavering commitment to quality, unmatched expertise, and continuous investment in research and development. Over the years, Silicone Parts has built a reputation for excellence in delivering cost-effective, durable, and efficient silicone parts for a wide range of applications, serving numerous industries, including automotive, healthcare, electronics, and more.2. Cutting-Edge Technology (about 150 words):Silicone Parts distinguishes itself from its competitors by staying ahead of the curve with its innovative use of cutting-edge technology. The company deploys state-of-the-art machinery and equipment in its manufacturing processes to ensure precision, consistency, and exceptional quality. By integrating advanced automation and robotics, Silicone Parts optimizes production efficiency without compromising on product excellence.3. Customization and Tailored Solutions (about 150 words):Understanding the unique requirements of different industries, Silicone Parts emphasizes the importance of customization. The company collaborates closely with its clients to develop tailored solutions that meet their specific needs. From concept to design to production, Silicone Parts provides comprehensive support, ensuring that their silicone parts align perfectly with customer expectations. This commitment to customization enables industries to achieve optimal performance and efficiency while reducing overall costs.4. Quality Assurance and Certifications (about 130 words):Silicone Parts places great emphasis on quality control systems to guarantee the reliability and longevity of their products. The company follows stringent quality assurance practices throughout the entire production process to maintain consistency and meet international standards. With certifications such as ISO 9001 and ISO 13485, Silicone Parts consistently proves its commitment to delivering excellence.5. Environmental Responsibility (about 140 words):As a responsible player in the silicone industry, Silicone Parts is constantly striving to minimize its environmental impact. The company adheres to strict sustainability practices, focusing on reducing waste, recycling, and implementing energy-efficient processes. Silicone Parts is actively involved in research and development initiatives to explore eco-friendly alternatives and ensure their products are eco-conscious.Conclusion (about 70 words):Silicone Parts serves as a catalyst for innovation, setting new standards within the silicone manufacturing industry. With its immense expertise, cutting-edge technology, commitment to customization, unwavering quality assurance, and sustainability efforts, the company aims to continue propelling the industry forward. Silicone Parts emerges as a trusted partner for industries aiming to optimize performance, enhance efficiency, and contribute to a greener future.

Top 5 Foam Cutting Router Bits for Precision Cutting

Foam Cutting Router Bits have revolutionized the way foam materials are cut and shaped. These bits are designed to be used with a router to effortlessly slice through foam with precision and ease. Their unique design allows for clean and efficient cuts, making them an essential tool for anyone working with foam materials.{Company Name} is a leading manufacturer and distributor of Foam Cutting Router Bits. With years of experience in the industry, they have perfected the art of creating high-quality bits that deliver exceptional results. Their dedication to innovation and customer satisfaction has established them as a trusted name in the foam cutting industry.The Foam Cutting Router Bits offered by {Company Name} are carefully crafted using the finest materials and cutting-edge technology. Each bit is precision-engineered to ensure optimal performance and durability. The company offers a wide range of bits, catering to various foam cutting needs. Whether it's for industrial applications or DIY projects, {Company Name} has a solution for every customer.One of the key features of {Company Name}'s Foam Cutting Router Bits is their ability to provide clean and precise cuts. The bits are designed to minimize foam tear-out and produce smooth edges, resulting in professional-looking pieces. This level of precision is crucial for industries such as packaging, upholstery, and insulation, where accuracy is paramount.Another advantage of using {Company Name}'s Foam Cutting Router Bits is their efficiency. The bits are engineered to cut through foam quickly and effortlessly, saving time and labor. This makes them ideal for large-scale foam cutting operations, allowing businesses to increase their productivity without compromising on quality.In addition to their performance, {Company Name}'s Foam Cutting Router Bits are also designed with user safety in mind. The bits are equipped with safety features that minimize the risk of accidents during operation, providing peace of mind for operators and workers.{Company Name} takes pride in offering not only top-quality products but also exceptional customer service. Their team of experts is dedicated to helping customers find the right foam cutting solution for their specific needs. Whether it's choosing the correct bit for a particular foam material or providing technical support, {Company Name} is committed to ensuring that their customers have a positive experience.Furthermore, {Company Name} also offers customization options for their Foam Cutting Router Bits. This allows customers to tailor the bits to their exact specifications, ensuring that they get the perfect tool for their foam cutting needs. This flexibility sets {Company Name} apart from other providers and has contributed to their reputation as an industry leader.As a responsible manufacturer, {Company Name} is also committed to sustainability. They strive to minimize their environmental impact through responsible production practices and the use of eco-friendly materials. This commitment to sustainability resonates with customers who are conscious of their carbon footprint and are seeking environmentally friendly solutions.In conclusion, {Company Name}'s Foam Cutting Router Bits are a game-changer for industries and individuals working with foam materials. Their superior quality, precision, efficiency, and commitment to customer satisfaction make them the go-to choice for foam cutting needs. With a focus on innovation and sustainability, {Company Name} continues to set the standard for excellence in the foam cutting industry. Whether it's for large-scale industrial operations or DIY projects, {Company Name} has the right solution for all foam cutting requirements.

Advanced Multi Component Injection Molding for Enhanced Product Development

Multi Component Injection Molding has become a prominent technique in the manufacturing industry, providing a wide range of benefits for producing complex and innovative products. {Company name}, a leading manufacturing company, has embraced this advanced technology to enhance their production capabilities and meet the growing demands of their customers.With Multi Component Injection Molding, {Company name} is able to create products with multiple materials and colors in a single molding process. This innovative technique allows for the integration of various functionalities into a single component, reducing the need for additional assembly processes and improving the overall efficiency of the production line. By utilizing this advanced molding technology, {Company name} can offer their customers greater design flexibility and product customization options, ultimately leading to the development of more innovative and marketable products.{Company name} has invested significantly in state-of-the-art Multi Component Injection Molding machines, leveraging the latest advancements in mold design and material compatibility. This has enabled them to expand their production capabilities and offer a wider range of products to their diverse customer base. In addition, the company has assembled a team of highly skilled engineers and technicians who are proficient in the operation and maintenance of the Multi Component Injection Molding machines, ensuring the consistent delivery of high-quality products.One of the key advantages of Multi Component Injection Molding is the ability to produce complex and intricate parts with a high degree of precision. {Company name} has leveraged this capability to manufacture a diverse range of products, including automotive components, consumer electronics, medical devices, and household appliances. The company's proficiency in Multi Component Injection Molding has allowed them to meet the stringent quality and performance standards of their customers, leading to high levels of customer satisfaction and long-term partnerships.Moreover, Multi Component Injection Molding has enabled {Company name} to optimize their production processes, reducing waste and enhancing cost efficiency. By consolidating multiple manufacturing steps into a single molding process, the company has been able to minimize material usage and streamline their production operations. This has not only resulted in cost savings for {Company name}, but has also contributed to their commitment to sustainability and environmental responsibility.Through the adoption of Multi Component Injection Molding, {Company name} has strengthened their position as a leading manufacturing company in the industry. They have demonstrated their ability to adapt to the evolving needs of the market and provide innovative solutions to their customers. With a focus on continuous improvement and technological advancement, {Company name} is well-equipped to meet the challenges and opportunities of the future, solidifying their status as a preferred partner for complex and sophisticated manufacturing projects.In conclusion, Multi Component Injection Molding has become a key differentiator for {Company name}, enabling them to expand their capabilities, enhance their product offerings, and improve their operational efficiency. By leveraging this advanced technology, the company is well-positioned to achieve sustained growth and success in the dynamic manufacturing industry. As they continue to invest in innovation and expertise, {Company name} is poised to deliver even greater value to their customers and make a lasting impact on the market.

Plastic Machining Prototype for CNC: A Guide to Rapid Prototyping

CNC Plastic Machining PrototypeIn recent news, {Company} has introduced a new and innovative CNC plastic machining prototype. This cutting-edge technology is set to revolutionize the plastic machining industry, offering precision and efficiency like never before.{Company} is a renowned leader in the manufacturing and production industry, specializing in advanced machining and prototype development. With a strong focus on innovation and quality, the company has consistently delivered high-performance solutions to a wide range of industries, including aerospace, automotive, medical, and more.The new CNC plastic machining prototype is the latest addition to {Company}'s impressive portfolio of advanced machining capabilities. This state-of-the-art technology is designed to meet the increasing demand for high-precision plastic components with complex geometries. The prototype offers unparalleled accuracy, speed, and consistency, making it an ideal solution for rapid prototyping and production of plastic parts.One of the key features of the CNC plastic machining prototype is its advanced automation and robotics capabilities. This allows for the seamless integration of CAD/CAM software, ensuring precise toolpath generation and efficient production processes. Additionally, the prototype is equipped with high-speed spindles and advanced cutting tools, enabling it to achieve tight tolerances and superior surface finishes.In addition to its technical capabilities, the CNC plastic machining prototype is also designed for versatility and flexibility. The machine is capable of handling a wide range of plastic materials, including ABS, acrylic, nylon, polycarbonate, and more. This allows for the production of diverse plastic components to meet the specific requirements of various applications.Moreover, {Company} has invested in skilled engineers and technicians who are well-versed in the latest machining techniques and technologies. This ensures that the CNC plastic machining prototype is operated and maintained by experts who have a deep understanding of plastic machining processes, materials, and tooling.{Company}'s commitment to quality and reliability is evident in its rigorous quality control processes. The CNC plastic machining prototype undergoes stringent inspection and testing to ensure that each component meets the highest standards of precision and performance. This dedication to quality assurance ensures that customers receive exceptional plastic components that meet their exact specifications.The introduction of the CNC plastic machining prototype is a testament to {Company}'s dedication to continuous improvement and innovation. The company's investment in cutting-edge technology reflects its commitment to providing customers with superior solutions that meet the evolving demands of the industry.As a leader in the manufacturing and production industry, {Company} is well-positioned to elevate the standards of plastic machining with its new CNC plastic machining prototype. This innovative technology is set to empower businesses across various sectors with the capabilities to develop complex plastic components with unmatched precision and efficiency.In conclusion, the introduction of the CNC plastic machining prototype by {Company} marks a significant milestone in the advancement of plastic machining technology. With its advanced capabilities, precision, and versatility, this new prototype is poised to set a new standard for the production of high-quality plastic components. As {Company} continues to drive innovation in the industry, businesses can expect to harness the full potential of CNC plastic machining for their manufacturing needs.