Quality Precision Components: Latest News and Updates

By:Admin

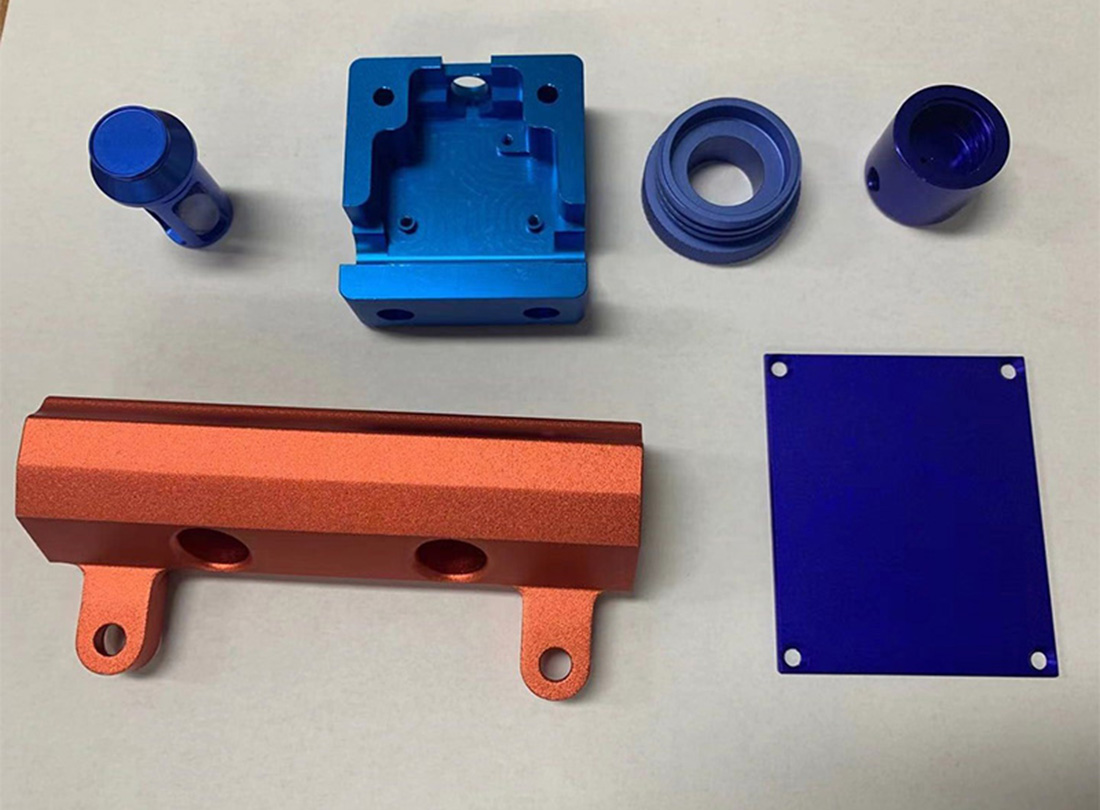

With over 20 years of experience, Machined Precision Components has established itself as a reliable and high-quality supplier of precision components to the aerospace, automotive, medical, and defense industries. The company's commitment to excellence and continuous improvement has earned it a reputation for delivering products of the highest standards.

Machined Precision Components is known for its state-of-the-art facilities and advanced technology, which allows it to produce complex components to the tightest tolerances. The company's team of highly skilled engineers and technicians are dedicated to meeting the exact requirements of its customers, ensuring that they receive products that meet their specifications and exceed their expectations.

One of the key factors behind Machined Precision Components’ success is its ability to adapt and evolve with the changing needs of its customers and the market. The company's investment in research and development has led to the creation of innovative new products that address the growing demand for high-performance components in various industries.

In line with its commitment to innovation, Machined Precision Components has recently expanded its product range to include a new line of components designed for the renewable energy sector. With the increasing focus on renewable energy sources, the demand for precision components for wind turbines, solar panels, and other renewable energy systems has been on the rise. Machined Precision Components has recognized this trend and has developed a range of components that are specifically tailored to meet the unique requirements of the renewable energy industry.

Furthermore, Machined Precision Components has also explored new opportunities in the electric vehicle (EV) market. As the automotive industry shifts towards electric and hybrid vehicles, there is a growing need for precision components that can meet the stringent requirements of these advanced vehicles. Machined Precision Components has leveraged its expertise in precision engineering to develop a range of components for electric and hybrid vehicles, positioning itself as a key player in this rapidly growing market.

In addition to its expansion into new markets, Machined Precision Components has also taken steps to enhance its production capabilities. The company has recently invested in new machinery and equipment to increase its capacity and efficiency, allowing it to meet the growing demand for its products while maintaining the highest standards of quality and precision.

The company's leadership and dedication to excellence are evident in its ISO 9001 certification, which demonstrates its commitment to quality management and continuous improvement. Machined Precision Components is also committed to environmental sustainability and has implemented various initiatives to reduce its environmental impact and promote sustainable practices.

With its expansion into new markets, introduction of innovative products, and ongoing commitment to excellence, Machined Precision Components is well-positioned to maintain its leadership in the precision component manufacturing industry. The company's relentless pursuit of quality and innovation sets it apart as a trusted partner for customers across various industries, and its dedication to meeting the evolving needs of the market ensures its continued success in the years to come.

Company News & Blog

Top Quality Plastic Injection Molding Services for Double Shot Products

Double Shot Plastic Pioneers Sustainable Innovations in Plastic ManufacturingIn today’s fast-paced world, innovation is key to staying ahead of the game. This is especially true in the plastic manufacturing industry, where sustainability and environmental consciousness are becoming increasingly important. One company that is leading the way in this regard is Double Shot Plastic, an industry pioneer in sustainable innovations in plastic manufacturing.Double Shot Plastic has gained a reputation for its commitment to producing high-quality plastic products while minimizing its impact on the environment. The company has invested heavily in state-of-the-art technology and processes to ensure that its manufacturing practices are as sustainable as possible.One of the company’s key innovations is its use of recycled plastics in its manufacturing processes. By utilizing recycled materials, Double Shot Plastic is able to reduce its reliance on virgin plastics, which helps to decrease the demand for new fossil fuels and reduces the amount of plastic waste in landfills.In addition to its use of recycled materials, Double Shot Plastic has also implemented energy-efficient practices in its manufacturing facilities. The company has invested in energy-efficient machinery and processes to minimize its carbon footprint and reduce its overall energy consumption.Furthermore, Double Shot Plastic is committed to ensuring that its products are recyclable at the end of their life cycle. The company works closely with its suppliers and customers to develop products that are easily recyclable, which helps to close the loop on the plastic production process and minimize waste.Double Shot Plastic’s dedication to sustainability extends beyond its manufacturing processes. The company has also made significant investments in research and development to explore new, more sustainable materials and processes. This has led to the development of innovative new products that are not only better for the environment, but also offer improved performance and durability.In addition to its focus on sustainability, Double Shot Plastic is also committed to maintaining the highest standards of quality in its products. The company uses rigorous testing and quality control processes to ensure that its products meet the highest industry standards, and its dedication to quality has earned it a strong reputation for reliability and consistency.Furthermore, Double Shot Plastic places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their specific needs and requirements, and it is committed to delivering products that meet or exceed their expectations. This customer-centric approach has helped the company to build long-lasting relationships with its clients and to become a trusted partner in the industry.Despite the challenges posed by the current global economic climate, Double Shot Plastic remains committed to its sustainability goals. The company continues to invest in new technology, research, and development to drive innovation and push the boundaries of what is possible in the plastic manufacturing industry.With its unwavering commitment to sustainability, quality, and customer satisfaction, Double Shot Plastic is setting a new standard for the industry. The company’s innovative approach to plastic manufacturing is not only helping to protect the environment, but also to create better, more sustainable products for the future.As the demand for sustainable plastic products continues to grow, Double Shot Plastic is well positioned to lead the way in the industry. By staying true to its core values and continuing to push the boundaries of what is possible, the company is poised to make an even greater impact on the industry in the years to come. With its dedication to sustainability and innovation, Double Shot Plastic is proving that it is possible to create a more sustainable future for the plastic manufacturing industry.

New Campaign Aims to Promote Mental Health Awareness and Support

Over 10,000 Customers Impacted by Cybersecurity Breach at {}{Company} is a leading provider of cybersecurity solutions and services, specializing in protecting businesses and individuals from cyber threats. With a strong track record of providing cutting-edge security technologies, {Company} has built a reputation as a trusted partner for safeguarding digital assets.However, the company recently faced a major challenge when it discovered a cybersecurity breach that affected over 10,000 of its customers. The breach, which occurred due to a sophisticated hacking attempt, resulted in unauthorized access to sensitive customer data, including personal information and financial records.The company immediately took swift action to address the breach, launching a full-scale investigation to determine the extent of the damage and identify the perpetrators behind the attack. {Company} also promptly notified all affected customers and provided them with guidance on how to protect themselves from potential identity theft and fraud.In a statement released to the press, {Company} CEO emphasized the company's commitment to customer security and vowed to take all necessary measures to prevent such breaches from happening in the future. "We deeply regret the inconvenience and concern caused to our customers by this breach," the CEO stated. "We are fully committed to addressing this issue and ensuring that our customers' data remains safe and secure."The cybersecurity breach at {Company} serves as a reminder of the growing threat of cyber attacks in today's digital landscape. As businesses and individuals increasingly rely on online platforms for their daily activities, the risk of falling victim to cyber threats continues to escalate. It is essential for companies and individuals alike to remain vigilant and take proactive steps to protect themselves from potential security breaches.{Company}, with its extensive experience and expertise in cybersecurity, is well-positioned to lead the fight against cyber threats. Through its advanced security technologies and proactive security measures, the company remains dedicated to helping businesses and individuals stay one step ahead of cyber criminals.Despite the recent breach, {Company} has also taken steps to enhance its security protocols and strengthen its defenses against future cyber attacks. The company has invested in state-of-the-art security solutions and implemented rigorous security measures to fortify its systems and protect customer data from unauthorized access.In response to the breach, many of {Company}'s customers have expressed their support for the company's efforts to mitigate the impact of the attack and improve its security infrastructure. "While the breach was concerning, I appreciate {Company}'s transparency and swift response in addressing the issue," one customer stated. "I trust that the company will take the necessary steps to prevent such incidents in the future."Moving forward, {Company} remains committed to upholding the highest standards of cybersecurity and maintaining the trust and confidence of its customers. The company's dedication to innovation and excellence in cybersecurity positions it as a leading player in the industry, with a strong focus on safeguarding digital assets and ensuring the security of online communications.As the cybersecurity landscape continues to evolve, {Company} stands at the forefront of the battle against cyber threats, equipped with the knowledge, expertise, and technology to protect businesses and individuals from a wide range of security risks. With its unwavering commitment to customer security and its proactive approach to cybersecurity, {Company} remains a trusted partner for safeguarding digital assets in an increasingly connected world.

How CNC Plastic Machining Prototypes Can Accelerate Product Development

CNC Plastic Machining Prototype is a cutting-edge technology that has revolutionized the manufacturing industry. This innovative process allows companies to create high-quality plastic prototypes with a high level of precision and accuracy. With the ability to produce complex shapes and designs, CNC plastic machining prototype has become an essential tool for companies looking to develop new products and test their ideas before full-scale production.One company that is leading the way in CNC plastic machining prototype is {}. Specializing in precision manufacturing and rapid prototyping, {} has established itself as a trusted partner for businesses looking to bring their product ideas to life. By leveraging the latest CNC technology and a team of highly skilled engineers, {} delivers top-quality plastic prototypes that meet the exact specifications of their clients.CNC plastic machining prototype offers a wide range of benefits for companies across various industries. One of the key advantages of this technology is the ability to create prototypes with intricate details and complex geometries. This level of precision is essential for companies developing products in industries such as aerospace, automotive, medical devices, and consumer electronics. With CNC plastic machining prototype, companies can test their designs and make adjustments before committing to full production, ultimately saving time and costs in the long run.In addition to its precision, CNC plastic machining prototype is also known for its speed and efficiency. Traditional methods of prototype production often involve time-consuming processes and manual labor, leading to longer lead times and higher costs. With CNC technology, {} is able to produce plastic prototypes in a fraction of the time, allowing their clients to iterate and refine their designs quickly and effectively.Furthermore, CNC plastic machining prototype is versatile and can accommodate a wide range of plastic materials. Whether it's ABS, polyethylene, polycarbonate, or any other type of plastic, {} has the expertise and capabilities to machine prototypes that meet the specific needs of their clients. This flexibility enables companies to explore different material options and identify the best fit for their final product, ensuring optimal performance and functionality.As a leading provider of CNC plastic machining prototype, {} is committed to delivering exceptional quality and customer satisfaction. Their team of engineers works closely with clients to understand their unique requirements and develop prototypes that exceed expectations. With a focus on continuous improvement and innovation, {} is dedicated to staying at the forefront of CNC technology and offering the best solutions for their clients' prototyping needs.In conclusion, CNC plastic machining prototype has emerged as a game-changing technology for companies looking to develop high-quality plastic prototypes. With its precision, speed, efficiency, and versatility, CNC technology has become an essential tool for businesses across various industries. As a trusted partner in precision manufacturing and rapid prototyping, {} continues to lead the way in delivering top-quality plastic prototypes that help their clients bring their product ideas to life.

High-Quality Thermoplastic Injection Molding Services for Your Business

Thermoplastic Injection Molding is a revolutionary manufacturing process that has taken the industry by storm. With the ability to create complex and intricate shapes with precision and efficiency, Thermoplastic Injection Molding has become the go-to method for producing high-quality plastic parts and components.One company that has been leading the way in Thermoplastic Injection Molding is {Company}. {Company} was established in 1990 and has since become a trusted name in the industry. They specialize in providing custom plastic injection molding solutions to a wide range of industries, including automotive, medical, consumer goods, and more.{Company} prides itself on its state-of-the-art facilities and cutting-edge technology, which allows them to produce superior quality products with unmatched precision and consistency. Their team of experienced engineers and technicians work tirelessly to ensure that every project they undertake meets the highest standards of excellence.With the increasing demand for complex and custom plastic parts, {Company} has been at the forefront of utilizing Thermoplastic Injection Molding to meet the needs of their clients. This advanced manufacturing process allows {Company} to produce high-quality plastic parts in large volumes, while maintaining tight tolerances and intricate designs.One of the key advantages of Thermoplastic Injection Molding is its ability to produce parts with a fast turnaround time. This means that {Company} is able to deliver their products to clients in a timely manner, helping them to meet their production deadlines and stay ahead of the competition.Furthermore, Thermoplastic Injection Molding offers cost-effective solutions for producing plastic parts, making it an attractive option for businesses looking to streamline their manufacturing processes and reduce production costs. {Company} understands the importance of delivering high-quality products at competitive prices, and their expertise in Thermoplastic Injection Molding allows them to do just that.{Company} also places a strong emphasis on sustainability and environmental responsibility. Thermoplastic Injection Molding is a highly efficient process that minimizes material waste, reduces energy consumption, and lowers the carbon footprint associated with manufacturing plastic parts. As a result, {Company} is able to offer eco-friendly solutions to their clients, helping them to minimize their environmental impact without compromising on quality or performance.In conclusion, Thermoplastic Injection Molding has revolutionized the way plastic parts are manufactured, and {Company} has been at the forefront of this innovation. Their commitment to excellence, advanced technology, and dedication to sustainability set them apart as a leader in the industry. As the demand for high-quality plastic parts continues to grow, {Company} is well positioned to meet the needs of their clients and provide innovative solutions through Thermoplastic Injection Molding.

Discover the Benefits of Large Injection Molding for Your Business

Large Injection Molding, a leading provider of injection molding services, has been making waves in the manufacturing industry with its state-of-the-art facilities and unmatched expertise. The company, which was founded in 1998, has established itself as a trusted partner for businesses looking for high-quality, precision-molded products.Based in the heart of the manufacturing industry, Large Injection Molding has set itself apart from the competition by consistently delivering superior results, from design to delivery. With a team of experienced engineers and technicians, the company is capable of handling complex projects with ease, providing clients with a seamless experience from start to finish.One of the key factors behind Large Injection Molding's success is its commitment to investing in cutting-edge technology. The company's facility is equipped with the latest injection molding machines, ranging from 50 to 1000 tons, allowing for the production of parts and products of various sizes and complexities. Additionally, the company's use of advanced software and automation systems ensures efficiency and accuracy in every project.But it's not just the technology that sets Large Injection Molding apart – it's also the company's dedication to quality and precision. Every product that comes out of the facility undergoes rigorous testing and inspection to ensure that it meets the highest standards. This commitment to excellence has earned Large Injection Molding a reputation for reliability and consistency among its clients.Furthermore, Large Injection Molding's capabilities extend beyond traditional injection molding. The company offers a range of services, including product design and development, tooling, and assembly, making it a one-stop shop for businesses in need of custom molded products. This comprehensive approach allows clients to streamline their manufacturing process and reduce time to market.Large Injection Molding has also made sustainability a priority. The company is committed to reducing its environmental impact by implementing eco-friendly manufacturing practices and using recycled materials whenever possible. This eco-conscious mindset has not only benefited the planet but has also enabled Large Injection Molding to attract environmentally conscious clients who value sustainability.In addition to its impressive capabilities, Large Injection Molding prides itself on its customer-centric approach. The company works closely with clients to understand their unique needs and requirements, offering personalized solutions that align with their goals. This commitment to customer satisfaction has earned Large Injection Molding long-lasting relationships with clients across a variety of industries, including automotive, aerospace, medical, and consumer products.Large Injection Molding's track record of success and innovation has not gone unnoticed. The company has been recognized with several industry awards and certifications, further solidifying its position as a leader in the injection molding field. Furthermore, Large Injection Molding continues to invest in its people, processes, and technology to stay ahead of the curve and remain at the forefront of the industry.Looking ahead, Large Injection Molding is poised for continued growth and success. With a focus on innovation, quality, and customer satisfaction, the company is well-equipped to meet the evolving needs of the manufacturing sector and contribute to the development of cutting-edge products for years to come.In conclusion, Large Injection Molding has established itself as a trusted partner for businesses in need of high-quality, precision-molded products. With its advanced technology, commitment to sustainability, and customer-centric approach, the company is well-positioned for continued success in the dynamic world of injection molding.

Precision CNC Machining for Aerospace Parts: Exploring the Latest Technologies and Techniques

Aerospace Parts Machining, a subsidiary of {}, is a leading provider of high-precision machined components for the aerospace industry. With a strong focus on quality and precision, Aerospace Parts Machining has established itself as a trusted partner for some of the biggest names in aerospace.Since its inception, Aerospace Parts Machining has been committed to delivering top-notch products and services to its customers. The company prides itself on its state-of-the-art facilities, cutting-edge technology, and highly skilled workforce, which allows it to meet the stringent demands of the aerospace industry.Aerospace Parts Machining specializes in the production of complex, tight-tolerance components that are critical to the functionality and safety of aircraft. The company's capabilities include CNC milling, turning, and grinding, as well as advanced inspection and testing processes to ensure that every part meets the highest standards of quality and accuracy.One of the key differentiators for Aerospace Parts Machining is its commitment to continuous improvement and innovation. The company heavily invests in research and development to stay ahead of the curve in terms of technology and manufacturing processes. This allows Aerospace Parts Machining to offer its customers the most advanced solutions for their aerospace machining needs.In addition to its technical capabilities, Aerospace Parts Machining is also known for its customer-centric approach. The company works closely with its clients to understand their specific requirements and challenges, and then provides tailored solutions to meet their needs. Whether it's a high-volume production run or a prototype development project, Aerospace Parts Machining has the expertise and flexibility to deliver.Aerospace Parts Machining's dedication to quality and customer satisfaction has earned it a strong reputation in the aerospace industry. The company has been recognized for its outstanding performance and has received numerous accolades and certifications from leading aerospace organizations. This includes meeting the stringent requirements of AS9100 certification, which is a testament to Aerospace Parts Machining's commitment to maintaining the highest standards of quality in its operations.As the aerospace industry continues to evolve and demand for more advanced and reliable components grows, Aerospace Parts Machining is well-positioned to meet the challenges. The company is continuously expanding its capabilities and capacity to ensure that it can fulfill the increasing demands of its customers in the aerospace sector.Looking ahead, Aerospace Parts Machining remains focused on driving innovation and pushing the boundaries of what is possible in aerospace machining. The company is exploring new technologies and processes to further enhance its capabilities and stay ahead of the competition. Additionally, Aerospace Parts Machining is committed to fostering strong partnerships with its customers and suppliers to create a sustainable and mutually beneficial ecosystem within the aerospace industry.In conclusion, Aerospace Parts Machining is a leading provider of high-precision machined components for the aerospace industry, known for its commitment to quality, innovation, and customer satisfaction. With its advanced capabilities and customer-centric approach, Aerospace Parts Machining is well-equipped to meet the ever-evolving needs of the aerospace industry and continue its track record of success in the years to come.

Innovative Rapid Prototyping Techniques Revolutionize Mechanical Engineering

Rapid Prototyping Advancements in Mechanical Engineering: {} Leading the WayIn the world of mechanical engineering, rapid prototyping is a game-changer. With the ability to quickly and cost-effectively produce prototypes and test designs, rapid prototyping has revolutionized the product development process. And at the forefront of this innovation is {}.{} is a leading provider of advanced manufacturing solutions, specializing in rapid prototyping and additive manufacturing technologies. With a strong commitment to delivering high-quality and accurate prototypes, {} has become a trusted partner for companies across various industries.One of the key factors that set {} apart is its dedication to staying ahead of the curve when it comes to advancements in mechanical engineering. The company's team of engineers and researchers are constantly pushing the boundaries of what is possible with rapid prototyping technology. By staying at the forefront of the latest developments in the field, {} is able to provide its clients with cutting-edge solutions that meet their specific needs and requirements.One of the most recent advancements in rapid prototyping is the development of new materials that offer improved mechanical properties and enhanced performance. {} has been at the forefront of integrating these new materials into its prototyping processes, allowing its clients to benefit from the latest innovations in the field. This has been particularly beneficial for companies in industries such as aerospace, automotive, and medical devices, where the demand for high-performance materials is critical.Another area of rapid prototyping that {} has been leading in is the development of more advanced and efficient prototyping processes. By leveraging the latest technologies and manufacturing techniques, {} has been able to significantly reduce production time and cost for its clients while maintaining the highest levels of quality and accuracy. This has allowed companies to accelerate their product development cycles and bring their designs to market faster than ever before.In addition to its technical expertise, {} also prides itself on providing outstanding customer service and support. The company's team of experts works closely with its clients to understand their unique needs and challenges, and develop tailored prototyping solutions that address these requirements. With a deep understanding of the industries it serves, {} is able to provide valuable insights and recommendations that help its clients achieve their goals more effectively.With its comprehensive capabilities and dedication to innovation, {} has solidified its position as a leader in rapid prototyping mechanical engineering. The company's commitment to pushing the boundaries of what is possible with rapid prototyping technology has set it apart from its competitors and positioned it as a go-to partner for companies looking to develop high-quality prototypes and bring their designs to market faster.Looking ahead, {} is poised to continue leading the way in rapid prototyping mechanical engineering, with a focus on further advancements in materials, processes, and technologies. By staying at the forefront of innovation, the company is well-positioned to help its clients succeed in an increasingly competitive and fast-paced market.In conclusion, the future of rapid prototyping mechanical engineering looks bright, and {} is at the forefront of this exciting evolution. With its dedication to innovation, technical expertise, and commitment to customer satisfaction, {} is leading the way in delivering cutting-edge rapid prototyping solutions that empower companies to bring their designs to life faster and more efficiently than ever before.

Top Aerospace CNC Machining Services for Precision Engineering

Aerospace CNC Machining, an industry leader in precision manufacturing, is proud to announce the addition of new cutting-edge equipment to their facility. With a focus on quality and efficiency, the company continues to invest in the latest technology to meet the demands of the aerospace industry.The company specializes in the manufacturing of complex and intricate components for the aerospace sector. Their state-of-the-art facility is equipped with advanced CNC machines that are capable of producing high-precision parts with tight tolerances. This technology allows Aerospace CNC Machining to meet the stringent requirements of the aerospace industry, where safety and reliability are of the utmost importance."We are committed to providing our customers with the highest quality products, and the addition of this new equipment reaffirms our dedication to excellence," said a spokesperson for Aerospace CNC Machining. "The aerospace industry demands precision and reliability, and our investment in the latest technology allows us to meet and exceed these standards."The new equipment includes advanced CNC milling and turning machines, as well as multi-axis machining centers. These machines offer increased productivity and efficiency, allowing Aerospace CNC Machining to reduce lead times and provide cost-effective solutions for their customers. Additionally, the company has invested in cutting-edge inspection equipment to ensure that all parts meet the strict quality standards required by the aerospace industry.In addition to their focus on technology and equipment, Aerospace CNC Machining places a strong emphasis on their workforce. Their team of highly skilled machinists and engineers are dedicated to delivering superior products and exceptional customer service. The company prides itself on its ability to provide innovative solutions to complex manufacturing challenges, and their team plays a crucial role in this success."We believe that our people are our greatest asset," said the spokesperson. "The expertise and dedication of our team are what sets us apart in the aerospace manufacturing industry. We are continuously investing in training and development to ensure that our employees have the skills and knowledge to deliver the highest quality products to our customers."Aerospace CNC Machining's commitment to excellence extends beyond their manufacturing capabilities. The company is dedicated to maintaining the highest standards of quality and safety in all aspects of their operations. They are certified to AS9100 and ISO 9001 standards, ensuring that their products and processes meet the rigorous requirements of the aerospace industry."We understand the critical nature of the components we manufacture, and the importance of adhering to strict quality and safety standards," said the spokesperson. "Our certifications and compliance with industry regulations demonstrate our commitment to delivering reliable and high-quality products to our customers."With their continued investment in technology, equipment, and workforce development, Aerospace CNC Machining is poised to remain at the forefront of the aerospace manufacturing industry. As they continue to grow and expand their capabilities, the company is well-positioned to meet the evolving needs of their customers and the aerospace industry as a whole.

Discover the Latest Small High Precision Lathe for Enhanced Precision

Small High Precision Lathe Revolutionizes Machining: A Game Changer for Manufacturing IndustriesIn today's rapidly evolving manufacturing landscape, precision and efficiency are of paramount importance. With the introduction of the groundbreaking Small High Precision Lathe, manufacturing companies around the world are set to experience a revolutionary change in their machining processes. Although we cannot mention the brand name, this cutting-edge technology promises to deliver exceptional results, ensuring heightened precision, unparalleled productivity, and reduced production time.Manufacturing has always been a complex and challenging process, requiring meticulous attention to detail and the use of advanced machinery. The Small High Precision Lathe, with its innovative features and capabilities, is set to enhance the performance of machining operations across various industries, including aerospace, automotive, and medical.With a compact and ergonomic design, this lathe utilizes state-of-the-art technology to achieve extraordinary precision. Its advanced control system, combined with specialized software, enables users to execute intricate machining tasks with ease and accuracy. The lathe's high spindle speed and exceptional torque ensure that even the most complex components can be machined with precision, meeting the stringent quality standards of modern industries.Beyond its impressive precision, the Small High Precision Lathe also offers remarkable versatility. Its adjustable tooling options and multiple-axis functionalities allow for a wide range of machining operations, from turning and facing to threading and knurling. The lathe's automatic tool change system further streamlines the manufacturing process, reducing downtime and boosting overall productivity.Companies that have already integrated this technology into their manufacturing processes have reported significant improvements in their operational efficiency. The Small High Precision Lathe's fast setup and programming capabilities enable rapid production, resulting in shorter lead times and increased output. Furthermore, the lathe's ability to handle both small and large batches of components makes it an invaluable asset for manufacturers of various scales.The implementation of this cutting-edge lathe technology also contributes to a greener and more sustainable manufacturing environment. Its energy-efficient design, coupled with optimized machining processes, reduces power consumption and promotes responsible production practices. As manufacturers strive to meet environmental regulations and reduce their carbon footprint, the Small High Precision Lathe aligns perfectly with their sustainability goals.While the Small High Precision Lathe delivers exceptional performance on its own, it also integrates seamlessly into existing manufacturing systems. Its compatibility with computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows for efficient data exchange, ensuring a smooth transition from design to production. Additionally, the lathe's remote monitoring and diagnostic features enable real-time troubleshooting, reducing maintenance costs and increasing equipment uptime.As the manufacturing industry continues to evolve, the demand for higher precision and efficiency will only intensify. The Small High Precision Lathe represents a significant leap forward in machining technology, addressing these demands head-on. Its sophisticated features, exceptional precision, and user-friendly interface make it an indispensable tool for manufacturers worldwide.With this cutting-edge technology, manufacturers can expect reduced costs, increased productivity, and improved product quality. The Small High Precision Lathe not only meets these expectations but also sets new standards for the industry as a whole. As manufacturing companies embrace this revolutionary technology, they are poised to gain a competitive edge in a rapidly evolving global market.In conclusion, the Small High Precision Lathe revolutionizes the manufacturing landscape, offering a game-changing solution to the precision machining challenges faced by industries today. By combining state-of-the-art technology, unrivaled precision, and unmatched versatility, this lathe promises to propel manufacturing companies into a new era of efficiency and productivity. With its compact design, advanced control system, and eco-friendly features, the Small High Precision Lathe is set to redefine the future of machining.

Durable Rubber Bumpers for Motorcycle Seats: A Must-Have Accessory

Motorcycle Seat Rubber Bumpers: A Key Innovation from {Company Name}{Company Name} has been at the forefront of designing and producing high-quality motorcycle parts and accessories for over a decade. With a strong commitment to innovation and a dedicated team of experts, the company has continuously pushed the boundaries to create products that meet the ever-evolving needs of motorcycle enthusiasts around the world.One of the company's latest innovations that has been making waves in the motorcycle industry is their Motorcycle Seat Rubber Bumpers. These small yet crucial components have been designed to provide enhanced comfort and stability to riders, addressing a common issue faced by many motorcycle enthusiasts.The Motorcycle Seat Rubber Bumpers are made from durable, high-quality rubber that is designed to withstand the harsh conditions of riding. These bumpers are strategically placed on the underside of the motorcycle seat to provide cushioning and support to the rider, making long rides more comfortable and enjoyable.One of the key features of {Company Name}'s Motorcycle Seat Rubber Bumpers is their universal fit, which makes them compatible with a wide range of motorcycle models. This ensures that riders can easily install these bumpers on their bikes without the need for any modifications, making them a convenient and practical solution for motorcycle enthusiasts.In addition to providing enhanced comfort, the Motorcycle Seat Rubber Bumpers also play a crucial role in improving the overall stability and balance of the motorcycle. By reducing vibrations and minimizing the impact of bumps and rough terrain, these bumpers help riders maintain better control of their bikes, ultimately enhancing their riding experience and safety.The team at {Company Name} takes great pride in the quality and functionality of their Motorcycle Seat Rubber Bumpers. Each bumper undergoes rigorous testing and quality checks to ensure that it meets the company's high standards and exceeds the expectations of their customers.Furthermore, {Company Name} is committed to sustainability and environmental responsibility. The materials used in the production of the Motorcycle Seat Rubber Bumpers are selected for their durability and eco-friendliness, aligning with the company's values of reducing their environmental impact.The introduction of the Motorcycle Seat Rubber Bumpers is a testament to {Company Name}'s dedication to innovation and customer satisfaction. This innovative product has been well-received by motorcycle enthusiasts, with many riders praising its performance and durability.In a statement, the CEO of {Company Name} expressed their excitement about the positive response to the Motorcycle Seat Rubber Bumpers, stating, "We are thrilled to see how our latest innovation is making a difference in the riding experience of motorcycle enthusiasts. The positive feedback and reviews we have received reaffirm our commitment to creating products that enhance comfort, performance, and safety for riders."With the success of the Motorcycle Seat Rubber Bumpers, {Company Name} is already looking ahead to their next innovative project. The company remains dedicated to pushing the boundaries of motorcycle design and engineering, with a focus on meeting the evolving needs of riders and delivering products that exceed expectations.Overall, the introduction of the Motorcycle Seat Rubber Bumpers from {Company Name} has proven to be a game-changer in the motorcycle industry. With its focus on comfort, stability, and quality, this innovative product has further solidified {Company Name}'s reputation as a leader in the design and production of high-quality motorcycle parts and accessories. Riders can look forward to more groundbreaking innovations from {Company Name} as they continue to push the boundaries of what is possible in the world of motorcycle engineering.