Create a Unique Prototype to Fit Your Needs with Customization Options

By:Admin

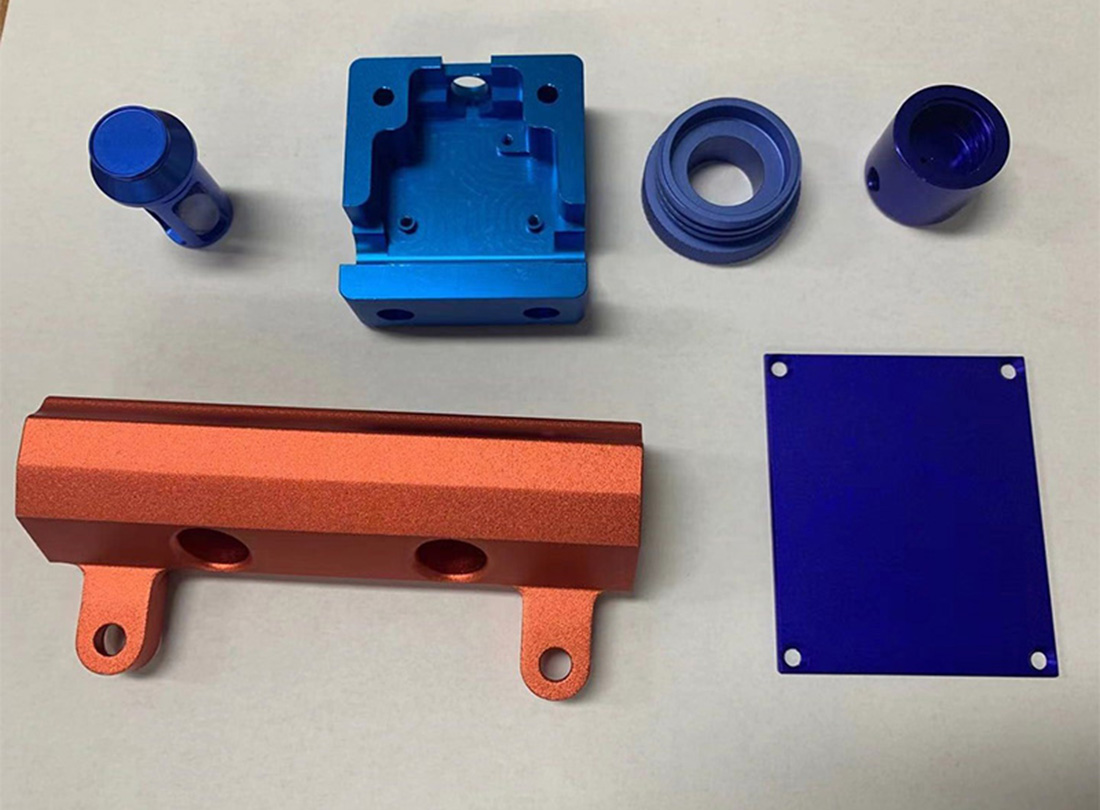

Innovative Company, a leading manufacturer in the tech industry, has unveiled its latest creation - a customized prototype that has the potential to revolutionize the industry. This new development is a result of the company's commitment to pushing the boundaries of technology and providing innovative solutions to their clients.

The customized prototype, which has been in development for several months, is a culmination of extensive research and development efforts by the company's team of experts. Designed to cater to the specific needs of their clients, this prototype is a testament to the company's dedication to delivering tailor-made solutions that go beyond the standard offerings available in the market.

The new prototype boasts a range of state-of-the-art features that set it apart from other products currently available. It is equipped with advanced technology that enables it to deliver superior performance and functionality. Additionally, the prototype is designed to be customizable, allowing clients to personalize it according to their specific requirements.

Innovative Company has a long-standing reputation for pushing the boundaries of technology and consistently delivering innovative products that cater to the evolving needs of their clients. With a strong focus on research and development, the company has been at the forefront of technological advancements and has consistently introduced groundbreaking products to the market.

The customization options available with the new prototype are a result of the company's commitment to providing tailored solutions to their clients. By understanding the unique requirements of each client, Innovative Company has been able to develop a prototype that can be adapted to meet a wide range of needs.

The unveiling of this customized prototype is a testament to the company’s dedication to innovation and their ability to stay ahead of the curve in a rapidly evolving industry. By continuously pushing the boundaries of technology, they have solidified their position as a leader in the market and have set a new standard for product development.

The company's commitment to innovation and customer satisfaction has been a driving force behind the development of this new prototype. By prioritizing the needs of their clients and investing in cutting-edge technology, they have been able to create a product that not only meets but exceeds expectations.

In addition to its advanced features and customizable options, the prototype also boasts a sleek and modern design that is visually appealing. This attention to detail is a reflection of the company’s commitment to delivering products that are not only high-performing but also aesthetically pleasing.

The unveiling of the customized prototype has generated significant excitement within the industry, with industry experts and clients expressing keen interest in the new product. It is expected to make a significant impact on the market and further solidify the company's position as a leader in technological innovation.

In conclusion, the unveiling of the customized prototype by Innovative Company is a testament to their unwavering commitment to innovation and customer satisfaction. With its advanced features, customizable options, and sleek design, this new development has set a new standard for product development in the tech industry. As the company continues to push the boundaries of technology, it is poised to make a significant impact on the market and transform the way clients engage with technology.

Company News & Blog

Benefits of Rapid Injection Molding for Quick and Affordable Production

Rapid Injection Molding: Revolutionizing Manufacturing ProcessesIn today's fast-paced world, innovation is a key driver of success. Companies are constantly seeking ways to improve their manufacturing processes, reduce time to market, and stay ahead of the competition. One of the most groundbreaking advancements in this regard is Rapid Injection Molding, a technology that has revolutionized the way products are designed and produced.At the forefront of this game-changing technology is a leading manufacturing company. With a strong emphasis on innovation and cutting-edge solutions, the company has established itself as a pioneer in the field of Rapid Injection Molding. By leveraging state-of-the-art equipment, advanced materials, and a highly skilled team, they have set a new standard for speed, precision, and efficiency in the industry.Rapid Injection Molding is a process that enables the rapid production of high-quality, precision-engineered plastic parts. Unlike traditional injection molding methods, which can be time-consuming and cost-prohibitive, Rapid Injection Molding offers a faster and more cost-effective solution. This is achieved through the use of advanced technology and streamlined production processes, allowing for quick turnaround times and reduced lead times.One of the key advantages of Rapid Injection Molding is its ability to significantly accelerate the product development cycle. By reducing the time required for tooling and production, companies can bring their products to market much faster, giving them a competitive edge in today's dynamic business environment. This not only allows for quicker product launches but also enables companies to respond more effectively to changing market demands and customer needs.Furthermore, Rapid Injection Molding offers unparalleled design flexibility. With the ability to quickly create and modify molds, companies can easily iterate on their designs and prototypes, leading to improved product quality and performance. This level of agility is essential in industries where innovation and differentiation are critical to success.In addition to speed and flexibility, Rapid Injection Molding also delivers exceptional quality and precision. The advanced technology and expertise employed by the company ensure that each part meets the strictest tolerances and specifications. This level of precision is essential for industries such as aerospace, automotive, medical devices, and consumer electronics, where reliability and performance are non-negotiable.Moreover, Rapid Injection Molding is a more sustainable and eco-friendly alternative to traditional manufacturing methods. By optimizing production processes and minimizing material waste, companies can reduce their environmental footprint and contribute to a more sustainable future.As a result of these benefits, Rapid Injection Molding has garnered widespread attention and adoption across various industries. Companies are increasingly turning to this technology to gain a competitive edge, reduce costs, and accelerate their time to market. With the demand for rapid and cost-effective manufacturing solutions on the rise, Rapid Injection Molding is poised to play an even more significant role in the future of production.In conclusion, Rapid Injection Molding is a game-changer that is revolutionizing the manufacturing landscape. With its ability to deliver speed, flexibility, precision, and sustainability, it has become a vital tool for companies looking to stay ahead in today's competitive market. As companies continue to embrace this cutting-edge technology, the possibilities for innovation and advancement are endless. The company's commitment to excellence and innovation will undoubtedly position them at the forefront of this transformative trend, shaping the future of manufacturing for years to come.

Benefits of Large Injection Molding for Industrial Manufacturing

Large Injection Molding Company Launches Innovative ProductsLarge Injection Molding, a leading company in the manufacturing industry, has recently announced the launch of their innovative new products. The company, known for its cutting-edge technology and commitment to quality, has developed a range of products that are set to revolutionize the industry.With a focus on innovation and customer satisfaction, Large Injection Molding has established itself as a trusted provider of high-quality injection molding solutions. The company’s state-of-the-art facilities and experienced team of engineers and designers have allowed them to stay at the forefront of the industry, consistently delivering products that exceed customer expectations.Large Injection Molding’s commitment to excellence is evident in their latest product offerings, which are designed to address the evolving needs of their customers. These new products are the result of extensive research and development, and they showcase the company’s dedication to staying ahead of the curve in a rapidly changing industry.One of the standout products in the company’s new lineup is their advanced mold design, which has been engineered to deliver superior performance and efficiency. Large Injection Molding’s innovative mold design implements the latest technology and materials to ensure maximum durability and precision, ultimately resulting in a longer product lifespan and reduced maintenance requirements.Another notable addition to the company’s product range is their cutting-edge injection molding machines, which have been designed to offer unmatched speed, accuracy, and versatility. These state-of-the-art machines are capable of handling a wide range of materials and designs, making them a valuable asset for customers with diverse manufacturing needs.In addition to their new mold design and injection molding machines, Large Injection Molding has also introduced an innovative range of custom plastic products. These products are tailored to meet the specific requirements of customers across various industries, and they are backed by the company’s commitment to quality and performance.“We are thrilled to introduce our latest products to the market,” said the spokesperson for Large Injection Molding. “These new offerings are a testament to our ongoing dedication to innovation and excellence, and we are confident that they will provide significant value to our customers.”With their new products now available to customers, Large Injection Molding is poised to continue its legacy of delivering superior solutions that drive efficiency, cost-effectiveness, and overall success for their clients. As the company continues to expand its product range and enhance its capabilities, it remains committed to upholding the highest standards of quality and reliability.About Large Injection MoldingLarge Injection Molding is a leading provider of high-quality injection molding solutions for a wide range of industries. With a focus on innovation, excellence, and customer satisfaction, the company has established a reputation as a trusted partner for businesses seeking cutting-edge manufacturing solutions. Large Injection Molding’s commitment to superior quality and performance has made them a preferred choice for customers across the globe, and their latest product offerings further solidify their position as an industry leader.For more information about Large Injection Molding and their innovative products, please visit their official website or contact the company directly.

Benefits of Urethane Cast Molding in Manufacturing Processes

Urethane Cast Molding, also known as urethane casting, has become a widely used manufacturing process in various industries due to its versatility and cost-effectiveness. This process is commonly used to create high-quality prototype and low-volume production parts that closely mimic the properties of injection molded parts, without the high tooling costs and long lead times associated with traditional injection molding. One company that has perfected the art of urethane cast molding is {}. Specializing in providing top-notch urethane cast parts for a wide range of industries, the company has established itself as a leader in the field of rapid prototyping and low-volume production.With over [XX] years of experience in the industry, {} has continually pushed the boundaries of what is possible with urethane cast molding. The company offers a wide range of urethane materials, including silicone, rigid and flexible urethanes, to meet the specific needs of their clients. Whether it's creating prototypes for consumer products, medical devices, automotive parts, or any other industry, {} has the expertise and capabilities to deliver high-quality parts that meet the most stringent requirements.One of the key advantages of urethane cast molding is its ability to produce parts with complex geometries and intricate details. This makes it an ideal process for rapid prototyping and low-volume production, where traditional manufacturing methods may not be suitable. The team at {} works closely with their clients to understand their needs and goals, and then leverages their expertise in urethane cast molding to deliver parts that not only meet, but exceed expectations.In addition to their technical expertise, {} also prides itself on its fast turnaround times and exceptional customer service. The company understands the importance of speed to market, and they are committed to delivering parts on time, every time. This dedication to customer satisfaction has earned them a reputation as a reliable and trustworthy partner in the industry.Another key differentiator for {} is their investment in cutting-edge technology and equipment. The company utilizes state-of-the-art 3D printing and machining capabilities to create high-quality master patterns, which are then used to create the molds for urethane casting. This attention to detail and commitment to quality sets {} apart from other urethane cast molding providers, and has made them a preferred choice for many companies looking for rapid prototyping and low-volume production solutions.As the demand for rapid prototyping and low-volume production continues to grow, {} is well-positioned to meet the needs of a wide range of industries. Whether it's creating functional prototypes for testing and validation, or producing low-volume production parts for market testing and initial production runs, {} has the expertise, capabilities, and dedication to quality to deliver superior results.In conclusion, {} has proven itself to be a leading provider of urethane cast molding solutions. With their technical expertise, commitment to customer satisfaction, and investment in advanced technology, the company is well-equipped to meet the evolving needs of the manufacturing industry. As the demand for rapid prototyping and low-volume production continues to rise, {} is poised to remain at the forefront of urethane cast molding, delivering top-notch parts that help their clients bring their products to market quickly and efficiently.

Unlock the Speed of Injection Molding with Quick Turn Services

[Content Removed - Brand Name]Introducing Quick Turn Injection Molding: Accelerating Manufacturing Processes[Company Name], a leading manufacturing company, is revolutionizing the industry with their innovative Quick Turn Injection Molding technology. This cutting-edge solution is set to streamline the manufacturing process, reduce production time, and improve overall efficiency.Traditional injection molding processes often take weeks, if not months, to deliver final products. However, with Quick Turn Injection Molding, [Company Name] provides a rapid manufacturing solution that significantly reduces lead times. This technology enables manufacturers to quickly prototype, refine, and produce high-quality end-products in record time.[Company Name] understands the importance of speed and efficiency in today's highly competitive market. Quick Turn Injection Molding allows manufacturers to accelerate their product development cycle, reaching the market faster than ever before. By decreasing the time it takes to go from initial concept to a finished product, businesses can maintain a competitive edge and capitalize on emerging trends.One of the key advantages of Quick Turn Injection Molding is its versatility. The technology supports an extensive range of materials, including various thermoplastics and elastomers. This feature allows manufacturers to choose the most suitable material for their products based on factors such as durability, desired appearance, or specific industry requirements.Moreover, [Company Name]'s expertise in Quick Turn Injection Molding ensures that the final products meet the highest quality standards. By employing advanced techniques and state-of-the-art machinery, the company guarantees precise and consistent results with each production run. This attention to detail ensures that manufacturers receive accurate prototypes and flawless end-products.In addition to speed and quality, Quick Turn Injection Molding also offers cost advantages. By reducing the lead time, manufacturers can optimize their production schedules, reduce inventory costs, and avoid potential financial constraints associated with longer production cycles. Furthermore, the technology allows for efficient customization and on-demand manufacturing, eliminating the need for large-scale production runs and minimizing unnecessary expenses.With Quick Turn Injection Molding, [Company Name] is enabling businesses to embrace agile manufacturing practices. The rapid prototyping capabilities offer manufacturers the flexibility to make quick design iterations, evaluate multiple concepts, and respond swiftly to market demands. This level of adaptability empowers businesses to align their products with evolving customer needs and preferences while taking advantage of emerging market opportunities.Embracing Quick Turn Injection Molding is not only beneficial for manufacturers but also for the entire supply chain. The shortened production cycles help to eliminate bottlenecks and reduce delays, resulting in faster delivery and improved customer satisfaction. Overall, this innovative technology has the potential to reshape the manufacturing landscape by fostering innovation, efficiency, and competitiveness.[Company Name] is dedicated to supporting its customers throughout the entire manufacturing process. Their team of experienced engineers and designers work closely with clients to understand their unique requirements and provide tailored solutions. From initial concept to final product, [Company Name] ensures a seamless experience for every client, supporting them in bringing their ideas to life.In conclusion, Quick Turn Injection Molding technology is a game-changer for the manufacturing industry. By combining speed, versatility, and superior quality, [Company Name] is paving the way for faster product development cycles, reduced costs, and increased competitiveness. With their expertise and commitment to excellence, [Company Name] continues to empower businesses to innovate, adapt, and succeed in a dynamic marketplace.

Revolutionizing Injection Molding: Efficiencies and Advancements Unveiled

[Assistant]Title: Innovative Injection Molds Revolutionize Manufacturing Process in the Plastic IndustryIntroduction:In the rapidly evolving world of manufacturing, injection molding has emerged as a game-changer, enabling the mass production of plastic products. With advanced technology and relentless dedication to innovation, [Company Name] has developed groundbreaking injection molds that are poised to revolutionize the industry. These molds not only streamline the manufacturing process but also enhance efficiency, quality, and customization options. By combining cutting-edge techniques with a commitment to sustainable practices, [Company Name] is redefining the way plastic products are manufactured.Body:1. Introduction to Injection Molding:Injection molding is a manufacturing process that involves injecting molten material, such as plastic, into a mold cavity. The molten material solidifies inside the mold, resulting in a precisely shaped, high-quality finished product. This process has gained immense popularity due to its ability to produce a wide range of products in large quantities, making it ideal for industries such as automotive, aerospace, consumer goods, and more.2. [Company Name]'s Innovative Approach to Injection Molding:Recognizing the potential of injection molding to transform the plastic industry, [Company Name] has taken innovative strides to push the boundaries of this technology. They have developed state-of-the-art injection molds that incorporate cutting-edge features, offering numerous advantages over traditional molds.3. Enhanced Efficiency and Precision:[Company Name]'s injection molds are engineered to optimize efficiency and precision. Through meticulous design and advanced manufacturing techniques, these molds facilitate faster cooling times, reducing production cycles and increasing productivity. Additionally, their molds incorporate advanced cavity and core design, resulting in superior product accuracy, eliminating the need for excessive post-production processes.4. Customization and Flexibility:Acknowledging the increasing demand for customized plastic products, [Company Name] has developed injection molds that provide unprecedented customization options. By leveraging their expertise in mold design and engineering, they offer clients the ability to create intricate and complex designs, meeting diverse requirements and surpassing expectations.5. Sustainability and Environmental Considerations:In keeping with the growing sustainability trends in the manufacturing industry, [Company Name] places a strong emphasis on eco-friendly practices. Their injection molds utilize advanced materials that reduce energy consumption and minimize waste generation, contributing to a greener manufacturing process. By integrating sustainable techniques, [Company Name] aims to establish itself as a responsible and environmentally-conscious industry leader.6. Collaborative Approach and Customer Satisfaction:[Company Name] believes in fostering strong partnerships with their clients. They work closely with manufacturers to understand their specific needs and offer tailored solutions. By providing comprehensive technical support and excellent after-sales service, [Company Name] ensures customer satisfaction at every stage of the manufacturing process.7. Competing in a Global Market:[Company Name] has set its sights on capturing a significant share of the global injection mold market. By leveraging their cutting-edge technology, commitment to innovation, and a highly skilled workforce, they are well-positioned to meet the increasing demand for high-quality, efficient, and customizable injection molding solutions.Conclusion:With their revolutionary injection molds, [Company Name] is poised to transform the plastic industry. By enhancing efficiency, precision, and customization options, they are reshaping the way plastic products are manufactured. Through their commitment to sustainability and customer satisfaction, [Company Name] has firmly established itself as a frontrunner in the global injection mold market. As the industry continues to evolve, [Company Name] will remain at the forefront, driving innovation and pushing the boundaries to meet the ever-growing demands of manufacturers worldwide.

High-Quality Precision Turned Parts: The Key to Optimal Performance

Precision Turned Parts, a leading manufacturer of high-quality precision turned components, is making waves in the industry with its innovative approach to precision engineering. With over 20 years of experience in the industry, Precision Turned Parts has earned a reputation for excellence and reliability.The company's commitment to precision engineering is evident in its state-of-the-art facilities, which are equipped with the latest technology and machinery. This allows Precision Turned Parts to produce components with tight tolerances and intricate designs, meeting the exact specifications of its customers.Precision Turned Parts prides itself on its ability to deliver high-quality components with a quick turnaround time. The company understands the importance of meeting deadlines and strives to exceed its customers' expectations with every order.In addition to its commitment to precision engineering, Precision Turned Parts places a strong emphasis on quality control. The company has rigorous quality assurance processes in place to ensure that every component it produces meets the highest standards of excellence. This dedication to quality has earned Precision Turned Parts the trust and loyalty of its customers, who rely on the company for their most critical projects.Precision Turned Parts serves a wide range of industries, including automotive, aerospace, medical, and electronics. The company's diverse portfolio of capabilities allows it to meet the unique needs of each industry, delivering customized solutions that enhance the performance of its customers' products.One of Precision Turned Parts' key strengths is its team of skilled engineers and technicians. The company's staff is highly trained and experienced, possessing the expertise to tackle even the most complex engineering challenges. This talented team is dedicated to pushing the boundaries of precision engineering, constantly seeking new ways to improve processes and deliver superior results.Precision Turned Parts is also committed to environmental sustainability, implementing eco-friendly practices throughout its operations. The company utilizes cutting-edge technology to minimize waste and reduce its carbon footprint, ensuring that its manufacturing processes are as sustainable as possible.As a customer-centric company, Precision Turned Parts places a strong emphasis on building long-term relationships with its clients. The company takes the time to understand the unique needs of each customer, working closely with them to develop tailored solutions that meet their specific requirements. This personalized approach has earned Precision Turned Parts a reputation for exceptional customer service and reliability.Looking to the future, Precision Turned Parts is committed to continued innovation and growth. The company is constantly investing in research and development to stay at the forefront of precision engineering, exploring new technologies and processes to further enhance its capabilities.With its unwavering commitment to precision engineering, exceptional quality, and dedication to customer satisfaction, Precision Turned Parts is poised to remain a leader in the industry for years to come. As the company continues to push the boundaries of what is possible in precision engineering, it will undoubtedly leave a lasting impact on its customers and the industry as a whole.

Custom Plastic Molding: Key Insights and Trends for 2022

Plastic Molding Company Continues to Lead the Industry in Innovation and Quality{Company name} has been a leading figure in the plastic molding industry for over two decades. The company, based in {location}, has established a strong reputation for delivering high-quality plastic molding solutions for a wide range of industries, including automotive, consumer goods, electronics, and medical devices. With a keen focus on innovation, sustainability, and customer satisfaction, {Company name} has become a go-to partner for businesses seeking reliable and efficient plastic molding services.The company's state-of-the-art manufacturing facility is equipped with the latest injection molding machines, automated robotic systems, and quality control processes. This allows {Company name} to consistently produce precision-engineered plastic components that meet the strictest industry standards.One of the key factors that sets {Company name} apart from its competitors is its commitment to sustainable practices. The company has invested in environmentally friendly manufacturing processes and materials, ensuring that its operations have a minimal impact on the environment. This dedication to sustainability has not only earned {Company name} recognition within the industry but has also attracted environmentally conscious clients seeking eco-friendly manufacturing solutions.In addition to its advanced manufacturing capabilities, {Company name} has built a team of highly skilled engineers and technicians who are dedicated to pushing the boundaries of plastic molding technology. The company regularly invests in research and development, allowing it to stay at the forefront of the industry and offer cutting-edge solutions to its clients.One such example of {Company name}'s commitment to innovation is its recent investment in 3D printing technology for rapid prototyping and product development. This investment has allowed the company to streamline its design and testing processes, ultimately reducing time to market for its clients. By leveraging 3D printing, {Company name} has demonstrated its adaptability and willingness to embrace emerging technologies, further cementing its position as an industry leader.Moreover, {Company name} understands that quality is paramount in the plastic molding industry. To ensure that its products meet the highest standards, the company has implemented rigorous quality control measures at every stage of the manufacturing process. From raw material inspection to final product testing, {Company name} is committed to delivering flawless plastic components that exceed customer expectations.Customer satisfaction is at the core of {Company name}'s business philosophy. The company works closely with each client to understand their unique requirements and provide tailored solutions that address their specific needs. This customer-centric approach has earned {Company name} a loyal customer base and a reputation for being a reliable and trusted partner in the plastic molding industry.Looking ahead, {Company name} remains focused on driving innovation and excellence in everything it does. The company continues to explore new technologies and processes to improve its manufacturing capabilities and expand its product offerings. Additionally, {Company name} is committed to fostering sustainable practices and minimizing its environmental footprint, aligning with the growing demand for eco-friendly manufacturing solutions.With its unwavering dedication to quality, innovation, and customer satisfaction, {Company name} is poised to remain a dominant force in the plastic molding industry for years to come. As the company continues to grow and expand its capabilities, it is well-positioned to meet the evolving needs of its clients and uphold its reputation as a leader in the industry.

Top Quality Plastic Injection Molding Services for Double Shot Products

Double Shot Plastic Pioneers Sustainable Innovations in Plastic ManufacturingIn today’s fast-paced world, innovation is key to staying ahead of the game. This is especially true in the plastic manufacturing industry, where sustainability and environmental consciousness are becoming increasingly important. One company that is leading the way in this regard is Double Shot Plastic, an industry pioneer in sustainable innovations in plastic manufacturing.Double Shot Plastic has gained a reputation for its commitment to producing high-quality plastic products while minimizing its impact on the environment. The company has invested heavily in state-of-the-art technology and processes to ensure that its manufacturing practices are as sustainable as possible.One of the company’s key innovations is its use of recycled plastics in its manufacturing processes. By utilizing recycled materials, Double Shot Plastic is able to reduce its reliance on virgin plastics, which helps to decrease the demand for new fossil fuels and reduces the amount of plastic waste in landfills.In addition to its use of recycled materials, Double Shot Plastic has also implemented energy-efficient practices in its manufacturing facilities. The company has invested in energy-efficient machinery and processes to minimize its carbon footprint and reduce its overall energy consumption.Furthermore, Double Shot Plastic is committed to ensuring that its products are recyclable at the end of their life cycle. The company works closely with its suppliers and customers to develop products that are easily recyclable, which helps to close the loop on the plastic production process and minimize waste.Double Shot Plastic’s dedication to sustainability extends beyond its manufacturing processes. The company has also made significant investments in research and development to explore new, more sustainable materials and processes. This has led to the development of innovative new products that are not only better for the environment, but also offer improved performance and durability.In addition to its focus on sustainability, Double Shot Plastic is also committed to maintaining the highest standards of quality in its products. The company uses rigorous testing and quality control processes to ensure that its products meet the highest industry standards, and its dedication to quality has earned it a strong reputation for reliability and consistency.Furthermore, Double Shot Plastic places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their specific needs and requirements, and it is committed to delivering products that meet or exceed their expectations. This customer-centric approach has helped the company to build long-lasting relationships with its clients and to become a trusted partner in the industry.Despite the challenges posed by the current global economic climate, Double Shot Plastic remains committed to its sustainability goals. The company continues to invest in new technology, research, and development to drive innovation and push the boundaries of what is possible in the plastic manufacturing industry.With its unwavering commitment to sustainability, quality, and customer satisfaction, Double Shot Plastic is setting a new standard for the industry. The company’s innovative approach to plastic manufacturing is not only helping to protect the environment, but also to create better, more sustainable products for the future.As the demand for sustainable plastic products continues to grow, Double Shot Plastic is well positioned to lead the way in the industry. By staying true to its core values and continuing to push the boundaries of what is possible, the company is poised to make an even greater impact on the industry in the years to come. With its dedication to sustainability and innovation, Double Shot Plastic is proving that it is possible to create a more sustainable future for the plastic manufacturing industry.

A Guide to Custom Metal Brackets: Uses and Applications

Custom Metal Brackets, a leading manufacturer of high-quality metal brackets for various industries, has announced the launch of their new line of innovative and customizable metal brackets. The company, with over 20 years of experience in the industry, is known for its commitment to producing top-notch products that meet the specific needs of their customers.Custom Metal Brackets specializes in providing custom solutions for a wide range of industries, including automotive, construction, aerospace, and more. Their team of skilled engineers and designers work closely with clients to understand their requirements and provide them with tailored solutions that meet their exact specifications.The new line of metal brackets features a range of customization options, including different sizes, shapes, materials, and finishes. This allows customers to create brackets that are perfectly suited to their specific applications, whether they are used for supporting heavy machinery, securing components in aerospace applications, or any other purpose.One of the key features of Custom Metal Brackets' new line is the ability to provide quick turnaround times without compromising on quality. With their advanced manufacturing capabilities and state-of-the-art equipment, the company is able to deliver custom metal brackets with short lead times, helping their clients meet tight deadlines and stay ahead of the competition.In addition to their customizable solutions, Custom Metal Brackets also places a strong emphasis on quality control and precision. Their team is committed to ensuring that every bracket they produce meets the highest standards of quality and accuracy, with thorough inspections and testing procedures in place to guarantee the reliability and performance of their products."We are excited to introduce our new line of customizable metal brackets to the market," said [Founder/CEO Name] of Custom Metal Brackets. "We understand the unique needs of our customers and are dedicated to providing them with the best possible solutions to help them succeed. With our new line, we aim to offer even greater flexibility and customization options to meet the diverse requirements of various industries."Custom Metal Brackets' commitment to excellence extends beyond their products to their customer service and support. The company prides itself on maintaining strong relationships with their clients, offering personalized assistance, expert guidance, and ongoing technical support to ensure that their customers have a seamless experience from design to production.With their new line of customizable metal brackets, Custom Metal Brackets aims to further solidify their position as a trusted and reliable partner for businesses in need of high-quality metal components. The company's dedication to innovation, precision, and customer satisfaction continues to set them apart in the industry and make them a go-to choice for custom metal brackets.For more information about Custom Metal Brackets, their new line of customizable metal brackets, and how they can help businesses with their metal component needs, visit their website at [website URL].

How CNC Machining is Used in Aircraft Part Manufacturing

In recent news, the aerospace industry has seen a significant advancement in the manufacturing of aircraft parts through the utilization of state-of-the-art CNC (Computer Numerical Control) machining technology. This cutting-edge technique has transformed the production process of aircraft components, allowing for higher precision, efficiency, and overall quality.One company at the forefront of this technological revolution is {}. With decades of experience in the aerospace industry, {} has established itself as a leader in the manufacturing and supply of aircraft parts for various commercial and military applications. The company's commitment to innovation and continuous improvement has led to the integration of advanced CNC machining capabilities into its production processes, setting a new standard for excellence in the industry.CNC machining has revolutionized the way aircraft parts are manufactured, offering a level of precision and accuracy that was previously unattainable through traditional manufacturing methods. By using computer-controlled machines and tools, {} is able to create complex and intricate aircraft components with unparalleled precision, resulting in parts that are not only highly reliable but also significantly lighter and more efficient.The use of CNC machining technology also allows for a streamlined production process, reducing lead times and enhancing overall productivity. With the ability to program and automate the machining process, {} can produce aircraft parts at a much faster rate, meeting the increasing demands of the aerospace industry without compromising on quality.Furthermore, CNC machining offers a level of consistency and repeatability that is essential in the aerospace sector. Each aircraft part manufactured using this technology adheres to the exact specifications and requirements, ensuring uniformity and reliability across the board. This level of consistency is crucial in the production of critical aircraft components, where even the smallest deviation can have significant repercussions.In addition to its precision and efficiency, CNC machining also allows {} to work with a wide range of materials, including aluminum, titanium, and composites, further expanding the company's capabilities in meeting the diverse needs of its customers. Whether it's a structural component or a complex engine part, {} has the expertise and technology to deliver high-quality aircraft parts that meet the stringent standards of the aerospace industry.The incorporation of CNC machining technology has not only elevated the production capabilities of {}, but it has also positioned the company as a frontrunner in the aerospace manufacturing sector. With a focus on continuous improvement and innovation, {} remains committed to pushing the boundaries of what is possible in aircraft part manufacturing, setting new benchmarks for quality, precision, and efficiency.As the aerospace industry continues to evolve and demand for more advanced and efficient aircraft components grows, the role of CNC machining in the manufacturing process will only become more significant. With {} leading the way in embracing this technology, the future of aircraft part manufacturing looks to be characterized by unprecedented levels of quality, precision, and reliability.In conclusion, the integration of CNC machining technology into the production processes of {} has brought about a transformative change in the way aircraft parts are manufactured. With a focus on precision, efficiency, and innovation, {} continues to set new standards for excellence in the aerospace industry, solidifying its position as a leading supplier of high-quality aircraft components. As the demand for advanced aerospace technology continues to rise, the role of CNC machining in the manufacturing of aircraft parts will undoubtedly play a crucial role in shaping the future of the industry.