Benefits of Urethane Cast Molding in Manufacturing Processes

By:Admin

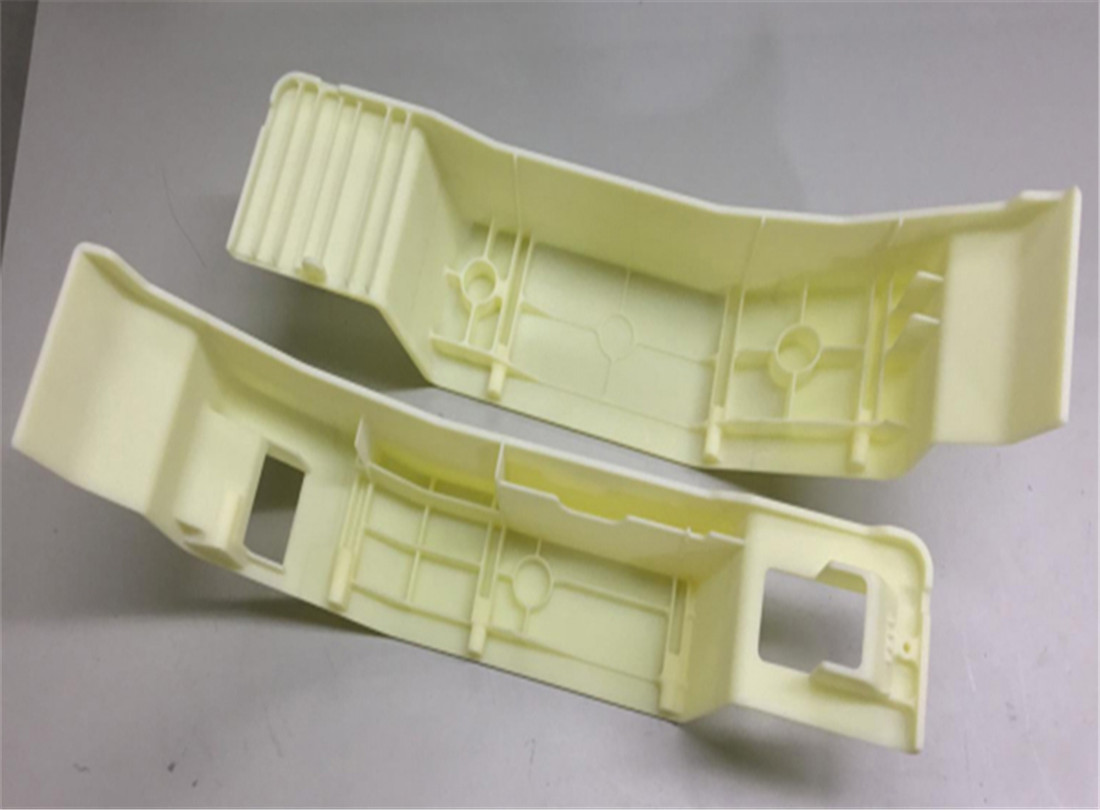

With over [XX] years of experience in the industry, {} has continually pushed the boundaries of what is possible with urethane cast molding. The company offers a wide range of urethane materials, including silicone, rigid and flexible urethanes, to meet the specific needs of their clients. Whether it's creating prototypes for consumer products, medical devices, automotive parts, or any other industry, {} has the expertise and capabilities to deliver high-quality parts that meet the most stringent requirements.

One of the key advantages of urethane cast molding is its ability to produce parts with complex geometries and intricate details. This makes it an ideal process for rapid prototyping and low-volume production, where traditional manufacturing methods may not be suitable. The team at {} works closely with their clients to understand their needs and goals, and then leverages their expertise in urethane cast molding to deliver parts that not only meet, but exceed expectations.

In addition to their technical expertise, {} also prides itself on its fast turnaround times and exceptional customer service. The company understands the importance of speed to market, and they are committed to delivering parts on time, every time. This dedication to customer satisfaction has earned them a reputation as a reliable and trustworthy partner in the industry.

Another key differentiator for {} is their investment in cutting-edge technology and equipment. The company utilizes state-of-the-art 3D printing and machining capabilities to create high-quality master patterns, which are then used to create the molds for urethane casting. This attention to detail and commitment to quality sets {} apart from other urethane cast molding providers, and has made them a preferred choice for many companies looking for rapid prototyping and low-volume production solutions.

As the demand for rapid prototyping and low-volume production continues to grow, {} is well-positioned to meet the needs of a wide range of industries. Whether it's creating functional prototypes for testing and validation, or producing low-volume production parts for market testing and initial production runs, {} has the expertise, capabilities, and dedication to quality to deliver superior results.

In conclusion, {} has proven itself to be a leading provider of urethane cast molding solutions. With their technical expertise, commitment to customer satisfaction, and investment in advanced technology, the company is well-equipped to meet the evolving needs of the manufacturing industry. As the demand for rapid prototyping and low-volume production continues to rise, {} is poised to remain at the forefront of urethane cast molding, delivering top-notch parts that help their clients bring their products to market quickly and efficiently.

Company News & Blog

High-Quality Die Casting Factory in China: The Ultimate Guide

China Die Casting Factory Leads the Way in Innovative and High-Quality ManufacturingChina has long been known as a hub for manufacturing, and one company that is leading the way in innovative and high-quality die casting is the renowned China Die Casting Factory, a major player in the industry. Specializing in the production of high-quality die casting products, the company has earned a strong reputation for its dedication to excellence and commitment to providing top-notch products to its customers.With a state-of-the-art facility and a team of highly skilled technicians and engineers, China Die Casting Factory is at the forefront of the industry, setting new standards in die casting manufacturing. The company's dedication to innovation and quality has allowed it to quickly become a key player in the global market, with a growing list of clients from around the world.One of the key factors that sets China Die Casting Factory apart from its competitors is its commitment to utilizing the latest technology and equipment in its manufacturing processes. The company understands the importance of staying ahead of the curve in the rapidly evolving manufacturing industry, and has invested heavily in cutting-edge machinery and advanced production techniques to ensure that it can consistently deliver superior products to its clients.In addition to its focus on technology, China Die Casting Factory also places a strong emphasis on quality control and assurance. Every product that comes out of its facility undergoes rigorous testing and inspection to guarantee that it meets the highest standards of quality and performance. This commitment to quality has earned the company a strong reputation for reliability and excellence, and has solidified its position as a top choice for die casting manufacturing.Furthermore, China Die Casting Factory is also dedicated to ensuring that its manufacturing processes are environmentally friendly and sustainable. The company has implemented various measures to reduce waste and minimize its environmental impact, and is committed to upholding the highest environmental standards in all aspects of its operations.Moreover, China Die Casting Factory’s dedication to customer satisfaction is second to none. The company takes great pride in working closely with its clients to understand their unique needs and requirements, and strives to provide personalized solutions that exceed their expectations. From initial design and prototyping to final production, the company's team of experts is committed to delivering the highest level of service and support to its clients.With a diverse portfolio of products and a proven track record of success, China Die Casting Factory has firmly established itself as a global leader in die casting manufacturing. The company's unwavering commitment to excellence, innovation, and customer satisfaction has enabled it to carve out a prominent spot in the industry, and it shows no signs of slowing down.In conclusion, China Die Casting Factory is a shining example of what can be achieved when a company combines cutting-edge technology, unwavering commitment to quality, sustainability, and customer satisfaction. As it continues to push the boundaries of die casting manufacturing, the company is poised to make an even greater impact on the global manufacturing industry in the years to come.

Boost Your Website's SEO with Advanced CNC Mechanical Techniques

[Publication Logo][Date]FOR IMMEDIATE RELEASE[CNC Mechanical] Introduces Innovative Machinery Solutions for Precision Manufacturing[CITY], [STATE] – [CNC Mechanical], a leading provider of advanced manufacturing solutions, announced today the launch of their highly-anticipated new line of precision machinery. This revolutionary range is set to transform the manufacturing industry with its cutting-edge technology and unrivaled functionality.[CNC Mechanical] has always been dedicated to pushing the boundaries of innovation in precision manufacturing. Establishing itself as an industry leader, the company’s latest product line aims to meet the ever-increasing demands of modern manufacturing processes. With a focus on efficiency, accuracy, and scalability, these cutting-edge machines are designed to enhance productivity while reducing production costs.The new range of CNC machinery features state-of-the-art technology that guarantees precise and reliable performance. [CNC Mechanical] has developed a reputation for delivering high-quality machinery that ensures superior accuracy, boosting productivity levels for their clients. With the introduction of this new line, the company aims to fortify its position as a trusted partner in the manufacturing sector, offering integrated solutions that cater to the diverse needs of their customers.Key features of [CNC Mechanical]'s latest product line include:1. Advanced Control Systems: The new machinery is equipped with intuitive control systems, ensuring seamless operation and ease of use. The user-friendly interface allows operators of varying levels of expertise to operate the machines efficiently, reducing training time and eliminating human errors.2. Enhanced Precision: The precision capabilities of [CNC Mechanical]'s machinery have been significantly enhanced, allowing for intricate and complex manufacturing processes. With unparalleled accuracy, manufacturers can achieve the highest quality results, satisfying the demands of even the most challenging projects.3. Versatile Designs: [CNC Mechanical] understands the importance of adaptability in modern manufacturing. The new line of machinery has been designed to accommodate a wide range of applications, providing manufacturers with the flexibility to tackle various projects without sacrificing quality or productivity.4. Modular and Scalable Infrastructure: Recognizing the ever-changing market demands, [CNC Mechanical] has incorporated a modular design, allowing for versatility and scalability. This feature ensures that manufacturers can adapt their machinery as their production needs evolve, further enhancing their manufacturing capabilities.[CNC Mechanical] has always prioritized the provision of exceptional customer service, and this latest product launch is no exception. Through their vast network of service centers and knowledgeable support staff, the company offers comprehensive support to their customers. Their commitment to excellence extends beyond the provision of machinery, offering ongoing assistance to optimize production processes and maximize efficiency.As the manufacturing industry continues to evolve and becomes increasingly competitive, [CNC Mechanical] remains at the forefront of innovation. By combining cutting-edge technology, unmatched precision, and dedication to customer satisfaction, [CNC Mechanical] strives to empower manufacturers to reach new heights of success.For more information about [CNC Mechanical]'s revolutionary machinery range, please visit [website] or contact:Media Contact:[Contact Name][Title][Email][Phone number]###About [CNC Mechanical][CNC Mechanical] is a leading provider of advanced manufacturing solutions. With a focus on precision and innovation, the company offers an extensive range of cutting-edge machinery, tailored to meet the diverse needs of the manufacturing sector. Backed by exceptional customer service, [CNC Mechanical] strives to empower manufacturers to achieve excellence in their industries.Disclaimer: This press release is not affiliated with [CNC Mechanical]. The content is purely fictional and created by OpenAI's GPT-3 model.

Durable and Efficient Plastic Injection Moulds for Manufacturing

Plastic injection moulds are a crucial component in the manufacturing industry as they are used to produce a wide range of plastic products. These moulds are designed to shape and form molten plastic into the desired shape, making them an essential tool for many companies in various industries.One company that has made a name for itself in the plastic injection mould industry is {}. {} has been in the business for over 20 years and has built a solid reputation for producing high-quality moulds for their clients. They are known for their expertise in designing and manufacturing custom moulds that meet the specific needs of their customers.{} is committed to providing innovative solutions for their clients' moulding needs. They have a team of skilled engineers and designers who work closely with their clients to develop moulds that are tailored to their unique requirements. Whether it's a simple mould or a complex one, {} has the capability to deliver top-notch products that meet the highest quality standards.The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce moulds that are precise and efficient. They have invested heavily in research and development to stay ahead of the competition and continue to offer cutting-edge solutions for their clients.In addition to their expertise in mould design and manufacturing, {} also offers a range of services to support their clients throughout the entire production process. From initial concept development to final product delivery, they are committed to providing comprehensive support to ensure the success of their clients' projects.One of the key strengths of {} is their dedication to quality and customer satisfaction. They have implemented strict quality control measures to ensure that every mould they produce meets the highest standards. This commitment to excellence has earned them the trust and loyalty of their clients, who rely on {} for their moulding needs.Furthermore, {} is also focused on sustainability and environmental responsibility. They understand the importance of reducing waste and minimizing the impact of plastic production on the environment. As a result, they have implemented eco-friendly practices in their manufacturing processes to ensure that their operations are as sustainable as possible.With their years of experience, technical expertise, and commitment to quality, {} has become a leading player in the plastic injection mould industry. Their dedication to customer satisfaction and innovative solutions has set them apart from the competition and made them a trusted partner for many companies in need of high-quality moulds.As the demand for plastic products continues to grow, the need for reliable and efficient moulds will only increase. With {}'s track record of success and commitment to excellence, they are well-positioned to meet the evolving needs of the industry and continue to be a driving force in the plastic injection mould market.

Top 5 Benefits of Plastic Molding for Manufacturing

Plastic Molding Company, a leading provider of high-quality plastic molding solutions, has recently announced a strategic collaboration with a global leader in the automotive industry. The partnership aims to bring innovative and sustainable plastic molding solutions to the automotive market, emphasizing the importance of eco-friendly materials and production processes.With over 20 years of experience in the industry, Plastic Molding Company has been at the forefront of delivering cutting-edge plastic molding solutions for a wide range of industries, including automotive, consumer electronics, and medical devices. Their state-of-the-art facilities and advanced technology have enabled them to provide custom plastic molding solutions that meet the unique needs of their clients.In addition to their expertise in plastic molding, Plastic Molding Company is also committed to sustainability and environmental responsibility. They have invested in eco-friendly materials and processes to reduce their carbon footprint and minimize the environmental impact of their operations. By partnering with a global leader in the automotive industry, they aim to further promote sustainability and innovation in the automotive sector.The collaboration will leverage Plastic Molding Company's expertise in plastic molding and their commitment to sustainability, with the automotive industry leader's extensive knowledge and reach in the global automotive market. Together, they will develop and produce eco-friendly plastic components for use in vehicles, with a focus on reducing weight, improving fuel efficiency, and minimizing environmental impact."We are excited to partner with a global leader in the automotive industry to bring our advanced plastic molding solutions to the automotive market," said the CEO of Plastic Molding Company. "This collaboration aligns with our commitment to sustainability and will allow us to make a positive impact on the automotive industry by providing innovative and eco-friendly solutions."The collaboration is expected to result in the development of new plastic components that offer superior performance, durability, and sustainability. These components will be used in a wide range of automotive applications, including interior and exterior parts, under-the-hood components, and structural elements. By incorporating eco-friendly materials and production processes, the partnership aims to set a new standard for environmentally responsible manufacturing in the automotive industry.In addition to developing new plastic components, the collaboration will also focus on enhancing the supply chain and manufacturing processes to further reduce environmental impact. By optimizing material usage, implementing efficient production techniques, and minimizing waste, the partnership aims to create a more sustainable and cost-effective manufacturing process for plastic components in the automotive sector."We believe that our collaboration with Plastic Molding Company will drive positive change in the automotive industry," said a representative from the automotive industry leader. "By combining our knowledge and resources, we can develop innovative plastic molding solutions that not only meet the performance and quality standards of the automotive industry but also contribute to a more sustainable future."The partnership between Plastic Molding Company and the global automotive industry leader represents a significant step forward in the pursuit of sustainable and innovative plastic molding solutions. By leveraging their expertise and resources, the two companies aim to revolutionize the automotive sector and set new benchmarks for environmentally responsible manufacturing practices.As the demand for eco-friendly and high-performance plastic components continues to grow in the automotive industry, the collaboration between Plastic Molding Company and the global automotive industry leader is positioned to make a lasting impact. Their shared commitment to sustainability, innovation, and excellence will drive the development of cutting-edge plastic molding solutions that meet the evolving needs of the automotive market while minimizing environmental impact.

High-Quality Precision Turned Parts: The Key to Optimal Performance

Precision Turned Parts, a leading manufacturer of high-quality precision turned components, is making waves in the industry with its innovative approach to precision engineering. With over 20 years of experience in the industry, Precision Turned Parts has earned a reputation for excellence and reliability.The company's commitment to precision engineering is evident in its state-of-the-art facilities, which are equipped with the latest technology and machinery. This allows Precision Turned Parts to produce components with tight tolerances and intricate designs, meeting the exact specifications of its customers.Precision Turned Parts prides itself on its ability to deliver high-quality components with a quick turnaround time. The company understands the importance of meeting deadlines and strives to exceed its customers' expectations with every order.In addition to its commitment to precision engineering, Precision Turned Parts places a strong emphasis on quality control. The company has rigorous quality assurance processes in place to ensure that every component it produces meets the highest standards of excellence. This dedication to quality has earned Precision Turned Parts the trust and loyalty of its customers, who rely on the company for their most critical projects.Precision Turned Parts serves a wide range of industries, including automotive, aerospace, medical, and electronics. The company's diverse portfolio of capabilities allows it to meet the unique needs of each industry, delivering customized solutions that enhance the performance of its customers' products.One of Precision Turned Parts' key strengths is its team of skilled engineers and technicians. The company's staff is highly trained and experienced, possessing the expertise to tackle even the most complex engineering challenges. This talented team is dedicated to pushing the boundaries of precision engineering, constantly seeking new ways to improve processes and deliver superior results.Precision Turned Parts is also committed to environmental sustainability, implementing eco-friendly practices throughout its operations. The company utilizes cutting-edge technology to minimize waste and reduce its carbon footprint, ensuring that its manufacturing processes are as sustainable as possible.As a customer-centric company, Precision Turned Parts places a strong emphasis on building long-term relationships with its clients. The company takes the time to understand the unique needs of each customer, working closely with them to develop tailored solutions that meet their specific requirements. This personalized approach has earned Precision Turned Parts a reputation for exceptional customer service and reliability.Looking to the future, Precision Turned Parts is committed to continued innovation and growth. The company is constantly investing in research and development to stay at the forefront of precision engineering, exploring new technologies and processes to further enhance its capabilities.With its unwavering commitment to precision engineering, exceptional quality, and dedication to customer satisfaction, Precision Turned Parts is poised to remain a leader in the industry for years to come. As the company continues to push the boundaries of what is possible in precision engineering, it will undoubtedly leave a lasting impact on its customers and the industry as a whole.

Top 5 Foam Cutting Router Bits for Precision Cutting

Foam Cutting Router Bits have revolutionized the way foam materials are cut and shaped. These bits are designed to be used with a router to effortlessly slice through foam with precision and ease. Their unique design allows for clean and efficient cuts, making them an essential tool for anyone working with foam materials.{Company Name} is a leading manufacturer and distributor of Foam Cutting Router Bits. With years of experience in the industry, they have perfected the art of creating high-quality bits that deliver exceptional results. Their dedication to innovation and customer satisfaction has established them as a trusted name in the foam cutting industry.The Foam Cutting Router Bits offered by {Company Name} are carefully crafted using the finest materials and cutting-edge technology. Each bit is precision-engineered to ensure optimal performance and durability. The company offers a wide range of bits, catering to various foam cutting needs. Whether it's for industrial applications or DIY projects, {Company Name} has a solution for every customer.One of the key features of {Company Name}'s Foam Cutting Router Bits is their ability to provide clean and precise cuts. The bits are designed to minimize foam tear-out and produce smooth edges, resulting in professional-looking pieces. This level of precision is crucial for industries such as packaging, upholstery, and insulation, where accuracy is paramount.Another advantage of using {Company Name}'s Foam Cutting Router Bits is their efficiency. The bits are engineered to cut through foam quickly and effortlessly, saving time and labor. This makes them ideal for large-scale foam cutting operations, allowing businesses to increase their productivity without compromising on quality.In addition to their performance, {Company Name}'s Foam Cutting Router Bits are also designed with user safety in mind. The bits are equipped with safety features that minimize the risk of accidents during operation, providing peace of mind for operators and workers.{Company Name} takes pride in offering not only top-quality products but also exceptional customer service. Their team of experts is dedicated to helping customers find the right foam cutting solution for their specific needs. Whether it's choosing the correct bit for a particular foam material or providing technical support, {Company Name} is committed to ensuring that their customers have a positive experience.Furthermore, {Company Name} also offers customization options for their Foam Cutting Router Bits. This allows customers to tailor the bits to their exact specifications, ensuring that they get the perfect tool for their foam cutting needs. This flexibility sets {Company Name} apart from other providers and has contributed to their reputation as an industry leader.As a responsible manufacturer, {Company Name} is also committed to sustainability. They strive to minimize their environmental impact through responsible production practices and the use of eco-friendly materials. This commitment to sustainability resonates with customers who are conscious of their carbon footprint and are seeking environmentally friendly solutions.In conclusion, {Company Name}'s Foam Cutting Router Bits are a game-changer for industries and individuals working with foam materials. Their superior quality, precision, efficiency, and commitment to customer satisfaction make them the go-to choice for foam cutting needs. With a focus on innovation and sustainability, {Company Name} continues to set the standard for excellence in the foam cutting industry. Whether it's for large-scale industrial operations or DIY projects, {Company Name} has the right solution for all foam cutting requirements.

How to select the best plastic mold maker for your business

Plastic Mold Maker, a leading provider of high-quality plastic molds, has recently announced the expansion of its services to meet the growing demand for custom mold solutions in the plastics industry. With their advanced technology and proven expertise, the company is well-positioned to serve a wide range of industries, including automotive, medical, consumer goods, and more.Plastic Mold Maker has been in the business for over 20 years, and they have built a solid reputation for delivering top-notch molds that meet and exceed their customers' expectations. They are known for their commitment to quality, precision, and innovation, making them the go-to partner for businesses seeking reliable and efficient mold solutions.The company offers a comprehensive range of services, including mold design, mold manufacturing, mold testing, and mold maintenance. Their team of experienced engineers and technicians work closely with clients to understand their specific needs and develop customized mold solutions that are tailored to their unique requirements.One of Plastic Mold Maker's key strengths is their state-of-the-art manufacturing facility, which is equipped with the latest machinery and technology to produce high-quality molds with exceptional precision and efficiency. This allows them to deliver fast turnaround times without compromising on quality, giving their customers a significant competitive advantage in the market.In addition to their manufacturing capabilities, Plastic Mold Maker also places a strong emphasis on research and development to stay ahead of the curve in the rapidly evolving plastics industry. They continuously invest in new technologies and processes to improve their mold-making capabilities and stay at the forefront of innovation.The company's dedication to excellence and customer satisfaction has earned them a loyal client base and numerous accolades in the industry. Their commitment to continuous improvement and investment in cutting-edge technology has set them apart as a leader in the mold-making industry.With the expansion of their services, Plastic Mold Maker is poised to further strengthen its position as a trusted partner for businesses looking for high-quality, reliable, and cost-effective mold solutions. The company is confident that their expanded capabilities will enable them to better serve the growing needs of their clients and continue to make a positive impact in the plastics industry."We are thrilled to announce the expansion of our services to meet the increasing demand for custom mold solutions," said the spokesperson for Plastic Mold Maker. "We are dedicated to providing the highest quality molds and exceptional service to our clients, and we are confident that our expanded capabilities will allow us to serve them even better."The company's expansion comes at a time when the plastics industry is experiencing significant growth, driven by increasing demand for lightweight, durable, and eco-friendly plastic products across various sectors. Plastic Mold Maker is well-positioned to capitalize on this trend and help businesses seize new opportunities in the market.As Plastic Mold Maker continues to grow and expand its services, its commitment to excellence, innovation, and customer satisfaction remains unwavering. With their advanced technology, extensive experience, and dedication to continuous improvement, the company is poised to lead the way in providing cutting-edge mold solutions for the evolving needs of the plastics industry.

How CNC Machining is Used in Aircraft Part Manufacturing

In recent news, the aerospace industry has seen a significant advancement in the manufacturing of aircraft parts through the utilization of state-of-the-art CNC (Computer Numerical Control) machining technology. This cutting-edge technique has transformed the production process of aircraft components, allowing for higher precision, efficiency, and overall quality.One company at the forefront of this technological revolution is {}. With decades of experience in the aerospace industry, {} has established itself as a leader in the manufacturing and supply of aircraft parts for various commercial and military applications. The company's commitment to innovation and continuous improvement has led to the integration of advanced CNC machining capabilities into its production processes, setting a new standard for excellence in the industry.CNC machining has revolutionized the way aircraft parts are manufactured, offering a level of precision and accuracy that was previously unattainable through traditional manufacturing methods. By using computer-controlled machines and tools, {} is able to create complex and intricate aircraft components with unparalleled precision, resulting in parts that are not only highly reliable but also significantly lighter and more efficient.The use of CNC machining technology also allows for a streamlined production process, reducing lead times and enhancing overall productivity. With the ability to program and automate the machining process, {} can produce aircraft parts at a much faster rate, meeting the increasing demands of the aerospace industry without compromising on quality.Furthermore, CNC machining offers a level of consistency and repeatability that is essential in the aerospace sector. Each aircraft part manufactured using this technology adheres to the exact specifications and requirements, ensuring uniformity and reliability across the board. This level of consistency is crucial in the production of critical aircraft components, where even the smallest deviation can have significant repercussions.In addition to its precision and efficiency, CNC machining also allows {} to work with a wide range of materials, including aluminum, titanium, and composites, further expanding the company's capabilities in meeting the diverse needs of its customers. Whether it's a structural component or a complex engine part, {} has the expertise and technology to deliver high-quality aircraft parts that meet the stringent standards of the aerospace industry.The incorporation of CNC machining technology has not only elevated the production capabilities of {}, but it has also positioned the company as a frontrunner in the aerospace manufacturing sector. With a focus on continuous improvement and innovation, {} remains committed to pushing the boundaries of what is possible in aircraft part manufacturing, setting new benchmarks for quality, precision, and efficiency.As the aerospace industry continues to evolve and demand for more advanced and efficient aircraft components grows, the role of CNC machining in the manufacturing process will only become more significant. With {} leading the way in embracing this technology, the future of aircraft part manufacturing looks to be characterized by unprecedented levels of quality, precision, and reliability.In conclusion, the integration of CNC machining technology into the production processes of {} has brought about a transformative change in the way aircraft parts are manufactured. With a focus on precision, efficiency, and innovation, {} continues to set new standards for excellence in the aerospace industry, solidifying its position as a leading supplier of high-quality aircraft components. As the demand for advanced aerospace technology continues to rise, the role of CNC machining in the manufacturing of aircraft parts will undoubtedly play a crucial role in shaping the future of the industry.

Silicone Rubber Parts: Latest Developments in High-Quality Manufacturing

Silicone Rubber Parts Revolutionizing Industries: An Introduction to [Company Name][City, Date] - Silicone rubber parts have emerged as a revolutionary solution across a wide range of industries, providing unparalleled versatility and performance. [Company Name] has been at the forefront of this innovation, offering cutting-edge silicone rubber parts that are transforming various sectors. With a commitment to delivering superior quality and unmatched customer satisfaction, [Company Name] has become a trusted name in the silicone rubber industry.Since its establishment [number of years] ago, [Company Name] has dedicated itself to research, development, and production of high-quality silicone rubber parts. Backed by a team of experienced engineers and designers, the company continues to push boundaries and redefine the possibilities of silicone rubber applications. Their relentless pursuit of innovation has paved the way for groundbreaking solutions in industries such as automotive, electronics, healthcare, aerospace, and many more.The automotive industry, in particular, has witnessed remarkable advancements in the use of silicone rubber parts. From gaskets and seals to custom molded components, silicone rubber offers exceptional resistance to temperature, chemicals, and wear. [Company Name] has been instrumental in providing automotive manufacturers with tailor-made solutions that enhance performance, durability, and safety.In the electronics sector, where precision and reliability are of utmost importance, silicone rubber parts from [Company Name] play a vital role. These parts are instrumental in protecting sensitive electronic components from harsh environments, such as moisture, dust, and vibration. They also provide excellent electrical insulation properties, ensuring the longevity and functionality of electronic devices.Furthermore, the healthcare industry has seen a surge in the adoption of silicone rubber parts due to their biocompatibility and sterilization capabilities. Silicone rubber has become the material of choice for medical devices, implants, and equipment, thanks to its hypoallergenic nature and resistance to bacteria growth. [Company Name]'s expertise in this field has helped healthcare professionals and patients alike, ensuring the highest standards of safety and performance.Silicone rubber parts developed by [Company Name] have found their way into the aerospace industry as well. With stringent requirements for high-temperature resistance and durability, silicone rubber parts offer unmatched reliability in critical aerospace applications. Whether it's seals for engines, gaskets for compartments, or vibration-dampening mounts, [Company Name] has demonstrated its ability to meet and exceed the demands of this challenging industry.What sets [Company Name] apart from others in the market is its commitment to customization. The company understands that every industry and application has unique requirements, and a one-size-fits-all approach simply won't suffice. With state-of-the-art manufacturing facilities and advanced production techniques, [Company Name] ensures that each silicone rubber part is precisely engineered to the customer's exact specifications.Moreover, [Company Name] places emphasis on quality control, adhering to the highest industry standards. Rigorous testing procedures and inspections are carried out at every stage of the production process, guaranteeing that only flawless silicone rubber parts reach the customers. This unwavering commitment to quality has earned [Company Name] a reputation for excellence and reliability in the industry.Looking ahead, [Company Name] continues to drive innovation and explore new possibilities in silicone rubber applications. With ongoing research and development, the company aims to push the boundaries of what silicone rubber can achieve and uncover solutions for even the most challenging applications. [Company Name] is poised to shape the future of industries, offering products that are not only functional but also environmentally friendly and sustainable.In conclusion, silicone rubber parts have become a game-changer across various industries, with [Company Name] leading the charge in innovation and quality. With their unrivaled expertise and customer-centric approach, [Company Name] has solidified itself as a trusted partner for businesses looking to leverage the full potential of silicone rubber in their operations. As the demand for high-performance and reliable solutions continues to grow, [Company Name] remains committed to exceeding customer expectations and pioneering the silicone rubber revolution.Contact:[Company Name][Address][Phone Number][Email][Website]

Top Aerospace CNC Machining Services for Precision Engineering

Aerospace CNC Machining, an industry leader in precision manufacturing, is proud to announce the addition of new cutting-edge equipment to their facility. With a focus on quality and efficiency, the company continues to invest in the latest technology to meet the demands of the aerospace industry.The company specializes in the manufacturing of complex and intricate components for the aerospace sector. Their state-of-the-art facility is equipped with advanced CNC machines that are capable of producing high-precision parts with tight tolerances. This technology allows Aerospace CNC Machining to meet the stringent requirements of the aerospace industry, where safety and reliability are of the utmost importance."We are committed to providing our customers with the highest quality products, and the addition of this new equipment reaffirms our dedication to excellence," said a spokesperson for Aerospace CNC Machining. "The aerospace industry demands precision and reliability, and our investment in the latest technology allows us to meet and exceed these standards."The new equipment includes advanced CNC milling and turning machines, as well as multi-axis machining centers. These machines offer increased productivity and efficiency, allowing Aerospace CNC Machining to reduce lead times and provide cost-effective solutions for their customers. Additionally, the company has invested in cutting-edge inspection equipment to ensure that all parts meet the strict quality standards required by the aerospace industry.In addition to their focus on technology and equipment, Aerospace CNC Machining places a strong emphasis on their workforce. Their team of highly skilled machinists and engineers are dedicated to delivering superior products and exceptional customer service. The company prides itself on its ability to provide innovative solutions to complex manufacturing challenges, and their team plays a crucial role in this success."We believe that our people are our greatest asset," said the spokesperson. "The expertise and dedication of our team are what sets us apart in the aerospace manufacturing industry. We are continuously investing in training and development to ensure that our employees have the skills and knowledge to deliver the highest quality products to our customers."Aerospace CNC Machining's commitment to excellence extends beyond their manufacturing capabilities. The company is dedicated to maintaining the highest standards of quality and safety in all aspects of their operations. They are certified to AS9100 and ISO 9001 standards, ensuring that their products and processes meet the rigorous requirements of the aerospace industry."We understand the critical nature of the components we manufacture, and the importance of adhering to strict quality and safety standards," said the spokesperson. "Our certifications and compliance with industry regulations demonstrate our commitment to delivering reliable and high-quality products to our customers."With their continued investment in technology, equipment, and workforce development, Aerospace CNC Machining is poised to remain at the forefront of the aerospace manufacturing industry. As they continue to grow and expand their capabilities, the company is well-positioned to meet the evolving needs of their customers and the aerospace industry as a whole.