Advanced Double Shot Injection Molding Process: The Ultimate Guide

By:Admin

{} is known for their commitment to pushing the boundaries of what is possible in the world of manufacturing. Their dedication to innovation and quality has allowed them to stay ahead of the competition and consistently deliver exceptional products to their clients. By investing in Double Shot Injection Molding, they have further solidified their position as a top-tier manufacturing company.

The process of Double Shot Injection Molding involves injecting two different materials into a single mold, resulting in a finished product with two layers or components. This opens up a world of possibilities for designers and engineers, allowing them to create parts with varying properties and functionalities. {} has fully integrated this technology into their production process, allowing them to offer their clients a wider range of options for their products.

One of the key advantages of Double Shot Injection Molding is its ability to reduce the need for secondary operations. With traditional manufacturing methods, producing multi-material parts often requires additional assembly or bonding processes. This not only adds time and cost to the production process but also increases the risk of defects. By using Double Shot Injection Molding, {} is able to create complex parts with seamless integration of different materials, eliminating the need for secondary operations and ensuring a higher level of quality and consistency.

In addition to streamlining the production process, Double Shot Injection Molding also allows for greater design freedom. {}'s team of engineers can now explore new possibilities in product design, creating parts with intricate geometries and unique material combinations. This level of flexibility has been invaluable to their clients, particularly those in industries such as automotive, consumer electronics, and medical devices, where the demand for highly specialized and innovative products is ever-increasing.

Furthermore, Double Shot Injection Molding has environmental benefits as well. By reducing the need for secondary operations and minimizing material waste, {} is able to operate in a more sustainable and eco-friendly manner. This aligns with their commitment to responsible manufacturing practices and positions them as an industry leader in both innovation and environmental stewardship.

As the demand for high-quality, multi-material parts continues to grow, {}'s investment in Double Shot Injection Molding has proven to be a wise decision. Their ability to offer a wider range of options to their clients, combined with their dedication to excellence and sustainability, has set them apart as a truly forward-thinking manufacturing company. With their continued focus on innovation, there's no doubt that {} will remain at the forefront of the industry for years to come.

Company News & Blog

Top Quality Large Plastic Molds for Your Industrial Needs

Large Plastic Molds, a leading manufacturer in the plastic molding industry, has announced its latest line of cutting-edge plastic molds. With over 20 years of experience in the industry, Large Plastic Molds has established itself as a reputable and reliable supplier of high-quality plastic molds.The company's commitment to innovation and excellence is evident in its new line of molds, which are designed to meet the growing demand for durable and precision-molded plastic products. Large Plastic Molds has invested heavily in state-of-the-art technology and equipment to ensure that its molds are of the highest quality and precision.The new line of plastic molds includes a wide range of products, ranging from small, intricate molds for electronic components to larger, more complex molds for automotive and industrial applications. Large Plastic Molds has also expanded its capabilities to include custom mold design and manufacturing, allowing customers to have molds tailored to their specific requirements.One of the key features of Large Plastic Molds' new line of molds is the use of advanced materials and manufacturing processes. The company has adopted the latest techniques in plastic molding, such as injection molding and blow molding, to create molds that are not only durable and reliable but also cost-effective and efficient.In addition to its cutting-edge technology, Large Plastic Molds is also committed to sustainability and environmental responsibility. The company has implemented rigorous quality control and waste management processes to minimize its environmental impact and ensure that its products are manufactured in an eco-friendly manner.Large Plastic Molds has also expanded its global reach and now serves customers in a wide range of industries, including electronics, automotive, consumer goods, and medical devices. The company's dedication to customer satisfaction and product quality has earned it a strong reputation in the industry, and it continues to be a preferred partner for many leading companies.In a recent statement, the CEO of Large Plastic Molds expressed excitement about the new line of molds, stating, "We are thrilled to introduce our latest line of plastic molds, which represent the culmination of years of research, development, and investment. These molds are a testament to our commitment to innovation and excellence, and we are confident that they will meet the needs of our customers in a variety of industries."The new line of plastic molds is now available for purchase, and Large Plastic Molds is actively seeking partnerships with companies looking for high-quality, reliable plastic molds. The company is also offering custom mold design and manufacturing services to meet the specific needs of its customers.With its dedication to innovation, excellence, and sustainability, Large Plastic Molds is well-positioned to continue its leadership in the plastic molding industry. As the demand for precision-molded plastic products continues to grow, Large Plastic Molds stands ready to meet the needs of its customers with its latest line of cutting-edge molds.

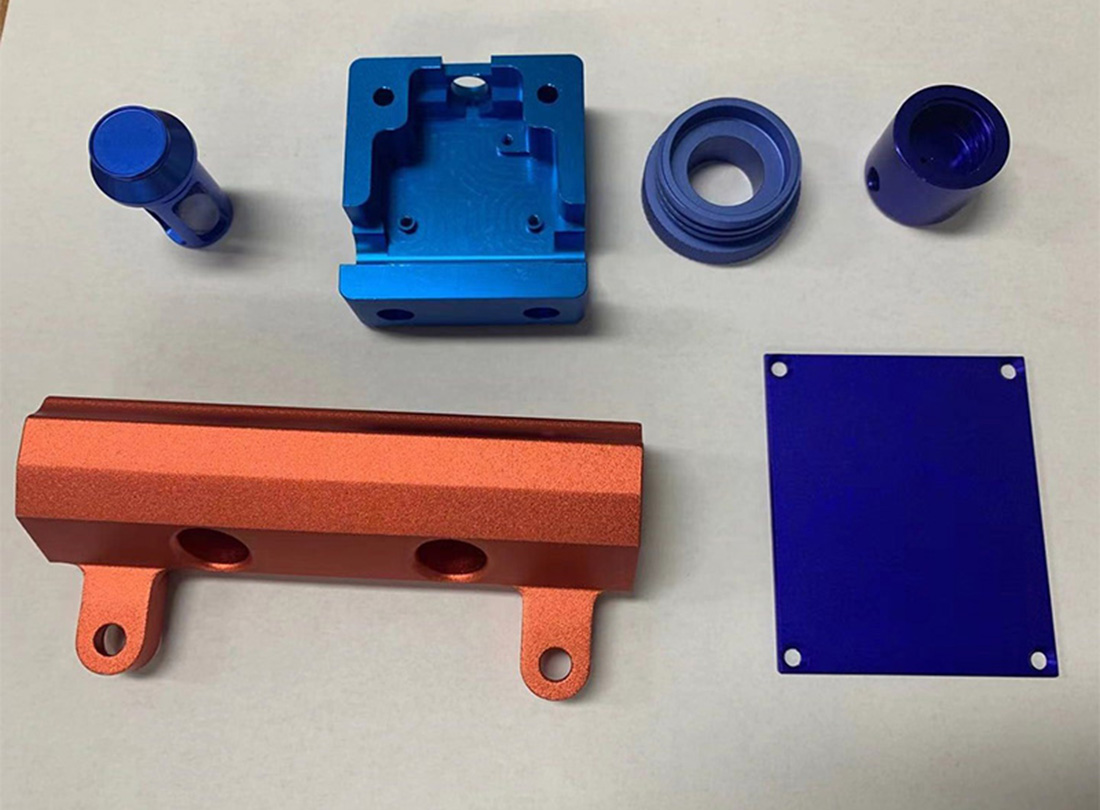

High-Quality Precision CNC Turning Milling Parts for Manufacturing Needs

CNC Turning Milling Parts: A High-Quality Addition to Our Product LineIn an exciting development for our company, we are proud to announce the addition of CNC turning milling parts to our extensive range of products. This new addition reflects our commitment to providing high-quality, precision-engineered components to our customers across a wide range of industries.Our company has a strong reputation for delivering excellence in manufacturing, and the introduction of CNC turning milling parts further enhances our capabilities. With state-of-the-art equipment and a team of skilled technicians, we are well positioned to meet the growing demand for these advanced manufacturing solutions.CNC turning milling parts offer numerous advantages, including enhanced precision, faster production times, and the ability to create complex geometries with ease. These parts are widely used in the automotive, aerospace, and medical industries, where tight tolerances and uncompromising quality are essential.By adding CNC turning milling parts to our product line, we are able to offer our customers a comprehensive solution for their manufacturing needs. Whether they require custom components for a specific application or high-volume production of a standardized part, we have the capabilities to deliver results that meet their exact specifications.Our investment in CNC turning milling parts is part of our ongoing commitment to staying at the forefront of manufacturing technology. We recognize the importance of continuously evolving our capabilities to meet the changing needs of our customers. With this latest addition, we are confident that we can offer even greater value to our clients and contribute to their continued success.In addition to the technical advantages of CNC turning milling parts, our company is also dedicated to upholding the highest standards of quality and reliability. Every part that we produce undergoes rigorous testing and inspection to ensure that it meets our stringent criteria for performance and durability.Furthermore, our team of engineers and manufacturing experts are always available to provide support and guidance to our customers. Whether they need assistance with design optimization, material selection, or production planning, we offer a wealth of knowledge and expertise to help them achieve the best possible results.The introduction of CNC turning milling parts is a significant milestone for our company, and we are excited about the opportunities it presents. As we continue to expand our capabilities, we remain focused on our core values of innovation, quality, and customer satisfaction.We are confident that the addition of CNC turning milling parts will further enhance our position as a leading provider of precision-engineered components. With a strong foundation built on expertise, technology, and a commitment to excellence, we look forward to serving our customers with the very best in manufacturing solutions.

High-Quality Aluminum Fabrication Sheet Metal Parts for Various Applications

Aluminum Fabrication Sheet Metal Parts: Leading The Way in Precision EngineeringIn today's fast-paced manufacturing industry, the demand for high-quality, precision-engineered metal parts is at an all-time high. The need for reliable, durable components has led to a growing interest in aluminum fabrication sheet metal parts. This demand has been met by the industry-leading precision engineering company, {}, who have been at the forefront of the aluminum fabrication sheet metal parts market for over a decade.{} is a renowned manufacturer of precision-engineered metal parts, specializing in aluminum fabrication sheet metal parts that are used in a wide range of industries, including aerospace, automotive, and electronics. With a commitment to quality and precision, {} has established itself as a trusted name in the industry and has garnered a reputation for delivering superior aluminum fabrication sheet metal parts to its clients.The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing them to produce aluminum fabrication sheet metal parts with unparalleled precision and accuracy. Their team of highly skilled engineers and technicians are dedicated to ensuring that every part meets the highest standards of quality, making {} a preferred choice for manufacturers in need of reliable and durable metal components.{}’s aluminum fabrication sheet metal parts are engineered to withstand the harshest of environments and are designed to meet the specific requirements of each client. Whether it's a complex aerospace component or a custom automotive part, {}’s expertise in aluminum fabrication sheet metal parts allows them to deliver superior products that exceed industry standards.One of the key factors that sets {} apart from its competitors is their commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve in the rapidly evolving manufacturing industry. This dedication to innovation has led to the development of advanced manufacturing techniques and processes, allowing {} to produce aluminum fabrication sheet metal parts that are both high-performing and cost-effective.In addition to their commitment to quality and innovation, {} places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, ensuring that every aluminum fabrication sheet metal part meets their exact specifications. This customer-centric approach has earned {} a loyal customer base, with clients returning time and again for their aluminum fabrication sheet metal part needs.With an unwavering commitment to quality, precision, and customer satisfaction, {} continues to lead the way in the aluminum fabrication sheet metal parts market. Their dedication to excellence has solidified their position as a trusted partner for manufacturers seeking high-quality, reliable metal components.As the demand for aluminum fabrication sheet metal parts continues to grow, {} remains focused on meeting the needs of their clients with innovative solutions and cutting-edge technology. With a track record of delivering excellence, {} is well-positioned to remain a leader in the precision engineering industry for years to come.

High-Quality Rubber Parts for Various Applications

Rubber Parts: A Vital Component in Various IndustriesRubber parts are an essential component in various industries, serving a wide range of applications and providing crucial functionalities. From automotive to aerospace, from manufacturing to consumer goods, rubber parts play a pivotal role in ensuring the smooth operation and performance of different products and equipment.One company that has been at the forefront of producing high-quality rubber parts is {}. With a strong commitment to excellence and innovation, {} has established itself as a leading manufacturer of rubber parts, catering to the diverse needs of its customers across the globe.Established in [year], {} has built a reputation for producing top-notch rubber parts that meet the highest standards of quality and performance. The company's extensive product range includes rubber seals, gaskets, O-rings, bushings, grommets, and various custom-molded rubber components. These products are designed to withstand extreme temperatures, harsh environments, and demanding operational conditions, making them suitable for a wide array of industrial applications.One of the key advantages of {} is its state-of-the-art manufacturing facilities and cutting-edge technologies. The company utilizes advanced molding processes, precision engineering, and quality control measures to ensure that its rubber parts adhere to the strictest specifications and requirements. This commitment to technological advancement and process efficiency allows {} to deliver products that not only meet but exceed the expectations of its customers.Furthermore, {} places a strong emphasis on research and development, constantly seeking to enhance the performance and capabilities of its rubber parts. The company invests in innovation, material science, and product design to stay ahead of the curve and provide its customers with the latest advancements in rubber technology. This forward-thinking approach allows {} to offer solutions that are tailored to the evolving needs of different industries, ensuring that its products remain at the forefront of technological advancements.In addition to its technical prowess, {} is also dedicated to upholding the highest standards of quality and reliability. The company is committed to achieving and maintaining various industry certifications, demonstrating its adherence to best practices and compliance with international standards. By prioritizing quality assurance and product excellence, {} instills confidence in its customers, assuring them that they are receiving rubber parts of the utmost caliber.Moreover, {} places great emphasis on customer satisfaction and responsiveness. The company strives to understand the unique requirements and challenges of its clients and works closely with them to provide tailored solutions that meet their specific needs. Whether it's customizing a product design, optimizing production processes, or providing technical support, {} goes the extra mile to ensure that its customers are fully supported and equipped with the right rubber parts for their applications.The versatility of {}'s rubber parts is demonstrated through their widespread use in various industries. In the automotive sector, {}'s rubber seals and gaskets are utilized in engines, transmissions, and other critical systems, providing reliable sealing and fluid containment. In the aerospace industry, its custom-molded rubber components are employed in aircraft systems, offering vibration isolation and shock absorption. In manufacturing, its O-rings and grommets are integral to machinery and equipment, ensuring leak-proof connections and protection of sensitive components.As the demand for high-performance rubber parts continues to rise across different sectors, {} remains at the forefront of the industry, delivering cutting-edge solutions that empower its customers and drive technological advancements. With its unwavering dedication to quality, innovation, and customer-centric approach, {} is poised to maintain its position as a leading provider of rubber parts, serving the evolving needs of diverse industries around the world.In conclusion, rubber parts are an indispensable element in numerous industries, playing a critical role in ensuring the efficiency, reliability, and safety of various products and equipment. Through its steadfast commitment to excellence, {} has positioned itself as a trusted manufacturer of top-quality rubber parts, continuously pushing the boundaries of innovation and meeting the dynamic demands of its customers. As industries continue to evolve and embrace new challenges, {} stands ready to provide the advanced rubber solutions needed to fuel progress and success.

Rubber Plugs Designed for Customized Hole Filling

In today's rapidly changing world, the need for customized solutions is more important than ever. When it comes to filling holes and gaps, one company has taken the initiative to create a tailored solution for a wide range of applications. With a dedication to innovation and quality, this company has developed a line of customized rubber plugs that are revolutionizing the way holes are filled.The company, headquartered in the heart of [location], has been a leading provider of industrial solutions for over [number] years. With a team of experienced engineers and technicians, they have gained a reputation for producing high-quality products that meet the specific needs of their customers. Their commitment to innovation and customer satisfaction has led them to develop a range of customized rubber plugs that are suitable for a variety of applications.These rubber plugs are made from high-quality materials that are durable, flexible, and resistant to environmental conditions. Whether it's filling small holes or sealing large gaps, the company's customized rubber plugs are designed to provide a tight and secure fit. This makes them ideal for use in industries such as automotive, construction, and manufacturing, where precision and reliability are of utmost importance.What sets these rubber plugs apart is their customizability. The company offers a range of options for customers to choose from, including different sizes, shapes, and materials. This means that no matter what the specific requirements are, the company can create a rubber plug that perfectly fits the bill. Whether it's a specific diameter, a non-standard shape, or a unique material, the company's engineers can work closely with customers to develop a plug that meets their exact specifications.In addition to their customizability, the company's rubber plugs are also designed for ease of use. They can be easily installed and removed, making them ideal for applications where frequent access to the filled holes is necessary. This not only saves time and effort but also improves overall efficiency and productivity.Furthermore, the company's commitment to sustainability is reflected in their rubber plugs. The materials used are eco-friendly and recyclable, making them an environmentally responsible choice for businesses looking to reduce their carbon footprint. This commitment to sustainability is just one example of the company's dedication to ethical business practices and corporate social responsibility.The company's rubber plugs have already made a significant impact in various industries. For example, in the automotive industry, they are being used to fill and seal holes in vehicles, ensuring that the interiors are protected from dust, moisture, and other contaminants. In the construction industry, they are being used to seal gaps in buildings, providing a secure and weatherproof barrier. And in the manufacturing industry, they are being used to plug holes in machinery, preventing leaks and ensuring smooth operation.Overall, the company's custom rubber plugs are proving to be a game-changer for businesses seeking tailored solutions for filling holes and gaps. With their focus on innovation, quality, and sustainability, they are setting a new standard for customized industrial products. As they continue to develop and refine their line of rubber plugs, it is clear that they are committed to meeting the evolving needs of their customers and the industries they serve.

Unlocking the Potential of Insert Moulding: Explore its Benefits and Applications

[News Headline]Innovative Insert Moulding Technology Enhances Efficiency and Durability in Manufacturing Processes[Subheading]Leading Manufacturing Company Unveils Remarkable Insert Moulding Technique That Revolutionizes the Industry[City, Date] - In a bid to revolutionize manufacturing processes, a renowned manufacturing company introduces an innovative insert moulding technology that enhances efficiency, durability, and cost-effectiveness. This groundbreaking technique aims to address long-standing challenges faced by various industries and is set to provide a significant boost to the manufacturing sector.[City, Date] - With the rapid advancement of technology, manufacturers strive to stay ahead of the curve by implementing cutting-edge techniques and technologies. With the rise in customer demand for improved efficiency, increased durability, and cost-effectiveness, companies such as [Company Name] have answered the call with their groundbreaking insert moulding technology.Insert moulding, also known as overmoulding, is a highly specialized manufacturing process that involves injecting a pre-formed component, such as metal, plastic, or electronic parts, into a plastic mould. This innovative technique provides multiple advantages over traditional manufacturing methods, making it an attractive option for a wide range of industries.One significant advantage of insert moulding is the enhanced durability it offers. The process ensures that the inserted component is securely encased within the plastic material, providing added protection from external forces, reducing the risk of damage and increasing the lifespan of the final product. This durability is particularly beneficial in industries that require high-performance components, such as the automotive, aerospace, and electronics sectors.Moreover, insert moulding significantly streamlines the manufacturing process. By combining multiple manufacturing steps into one, companies can save time and resources, ultimately reducing production costs. This streamlined approach also reduces the potential for errors and inconsistencies commonly associated with manual assembly, ensuring a more precise and uniform final product.With the advent of insert moulding, manufacturers can also explore more intricate and complex designs. This technique allows for the creation of parts with intricate geometries and multiple materials, expanding the possibilities for innovative product design. Additionally, insert moulding enables designers to incorporate multiple functionalities into a single component, further enhancing efficiency and overall product performance.Speaking at a recent press conference, [Company Name]'s spokesperson highlighted the benefits of their insert moulding technology. "As a leader in the manufacturing industry, we continually strive to push the boundaries of innovation. Our insert moulding technique offers unparalleled advantages, ranging from increased durability and efficiency to expanded design possibilities. We are excited to provide our clients with this cutting-edge solution that can unlock significant improvements in their manufacturing processes."The introduction of insert moulding into the manufacturing industry marks a pivotal stage in the evolution of production techniques. With the increasing demand for efficient, durable, and cost-effective products, companies must adapt and embrace innovative technologies such as insert moulding to remain competitive.As various industries adopt this remarkable technology, it is expected to revolutionize production processes across the board. From automotive and aerospace to electronics and medical sectors, insert moulding will undoubtedly drive efficiency and durability to new heights, benefiting manufacturers and end-users alike.In a rapidly changing world, the introduction of insert moulding technology demonstrates the ability of companies like [Company Name] to continually innovate and provide solutions that meet the evolving needs of the manufacturing industry. As the demand for enhanced efficiency and durability continues to grow, insert moulding proves to be a game-changer for businesses aiming to stay ahead in a highly competitive market.

Top Quality Spinning Spare Parts Manufacturers in China

China Spinning Spare Parts Manufacturers, a leading manufacturer of high-quality spare parts for the spinning industry, has been making waves in the global market with its innovative and reliable products. With a strong focus on research and development, the company has established itself as a trusted supplier of premium spinning spare parts to textile companies around the world.Established in [], China Spinning Spare Parts Manufacturers has quickly risen to prominence due to its commitment to delivering top-notch products that meet the highest industry standards. The company prides itself on its state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery to ensure the production of superior-quality spare parts.One of the key factors behind the company's success is its unwavering dedication to research and development. China Spinning Spare Parts Manufacturers has a team of highly skilled engineers and technicians who are constantly working on developing new and improved products. This focus on innovation has allowed the company to stay ahead of the competition and meet the evolving needs of the spinning industry.In addition to its commitment to innovation, China Spinning Spare Parts Manufacturers places a strong emphasis on quality control. The company follows stringent quality control measures at every stage of the production process to ensure that each spare part meets the highest quality standards. This dedication to quality has earned the company a stellar reputation for delivering products that are reliable, durable, and long-lasting.Furthermore, China Spinning Spare Parts Manufacturers is known for its excellent customer service. The company has a team of dedicated professionals who are committed to providing exceptional service to their clients. Whether it's providing technical support or fulfilling custom orders, the company goes above and beyond to ensure that its customers are completely satisfied with their experience.With its strong focus on innovation, quality, and customer service, China Spinning Spare Parts Manufacturers has become a preferred supplier for textile companies worldwide. The company's extensive product range includes a variety of spare parts for spinning machinery, such as spinning frames, roving frames, and ring spinning frames. Each product is designed to optimize the performance of spinning machines and improve overall productivity.The company's commitment to excellence has earned it numerous accolades and certifications, further validating its position as a leading manufacturer of spinning spare parts. China Spinning Spare Parts Manufacturers has received ISO 9001 certification, which underscores its dedication to maintaining the highest quality standards. Additionally, the company has been recognized for its contributions to the spinning industry through various awards and accolades.Looking ahead, China Spinning Spare Parts Manufacturers is poised for continued growth and success in the global market. The company remains steadfast in its commitment to innovation, quality, and customer satisfaction, and is constantly exploring new opportunities to expand its product range and reach new markets. With a strong focus on meeting the evolving needs of the spinning industry, China Spinning Spare Parts Manufacturers is well-positioned to maintain its status as a trusted and valued supplier of premium spinning spare parts.As the demand for high-quality spinning spare parts continues to rise, China Spinning Spare Parts Manufacturers is ready to meet the needs of textile companies around the world. With its unwavering dedication to excellence and a proven track record of delivering superior products, the company is set to remain at the forefront of the spinning industry for years to come.

Achieve Precision Results with Complex CNC Machining Parts

Introducing the New CNC Machining Complex PartsIn the ever-evolving world of manufacturing, precision and complexity are key factors that drive innovation and advancement. The demand for complex parts that meet the highest standards of quality and accuracy continues to grow, pushing manufacturers to seek advanced solutions to meet these requirements. With this in mind, {Company Name}, a leading provider of manufacturing solutions, is proud to introduce its new CNC Machining Complex Parts, poised to revolutionize the industry.The new CNC Machining Complex Parts from {Company Name} are designed to meet the complex needs of modern manufacturing. These parts are manufactured using state-of-the-art CNC machining technology, which allows for unparalleled accuracy, precision, and repeatability. This advanced machining process enables the production of complex parts with intricate geometries and tight tolerances, making them suitable for a wide range of industries, including aerospace, automotive, medical, and more.The CNC Machining Complex Parts offered by {Company Name} are the result of years of research, development, and innovation. The company's team of expert engineers and technicians have worked tirelessly to develop a manufacturing process that ensures the highest quality standards while also meeting the demands of today's complex manufacturing requirements. By leveraging advanced CNC machining technology, they have been able to achieve a level of precision and accuracy that was once thought to be unattainable.One of the key features of the new CNC Machining Complex Parts is their ability to produce parts with complex geometries and intricate designs. This opens up a world of possibilities for manufacturers, allowing them to create components and products that were previously deemed too complex or challenging to produce. The CNC Machining Complex Parts can also be manufactured in a wide range of materials, including aluminum, steel, titanium, and various other alloys, making them suitable for a diverse array of applications.Furthermore, the CNC Machining Complex Parts from {Company Name} are produced with efficiency and cost-effectiveness in mind. The advanced CNC machining technology allows for faster production times and lower manufacturing costs, without compromising on quality or accuracy. This makes these parts not only suitable for high-end, specialized applications, but also for large-scale production, where efficiency and cost-effectiveness are crucial considerations.{Company Name} prides itself on its commitment to quality, innovation, and customer satisfaction. The introduction of the new CNC Machining Complex Parts is a testament to this commitment, as it represents a significant leap forward in the company's capabilities and offerings. With these new parts, {Company Name} aims to provide its customers with the tools they need to stay ahead in today's competitive manufacturing landscape, offering unmatched quality, precision, and reliability.In conclusion, the new CNC Machining Complex Parts from {Company Name} are set to redefine the standards of manufacturing. By leveraging advanced CNC machining technology, the company has created a solution that meets the complex needs of modern manufacturing, offering unparalleled precision, complexity, and efficiency. With these new parts, {Company Name} continues to solidify its position as a leader in the industry, delivering innovative solutions that empower manufacturers to push the boundaries of what is possible.

Custom Molded Plastic Parts: A Key Component in Manufacturing

Pla Molded Parts Company, a leading provider of sustainable packaging solutions, has recently announced the launch of a new line of eco-friendly molded parts. The company, which has been in the business for over two decades, has established itself as a pioneer in the development and production of biodegradable packaging materials. With the increasing global concern for environmental sustainability, Pla Molded Parts Company has been at the forefront of introducing innovative and green solutions to the market.The new line of Pla molded parts is made from polylactic acid, a biodegradable and compostable thermoplastic derived from renewable resources such as corn starch or sugarcane. This material offers the same strength and durability as traditional plastics, making it an ideal choice for a wide range of applications, including packaging for food, beverages, electronics, and consumer goods.In addition to being environmentally friendly, Pla molded parts offer several benefits over conventional plastics. They are heat-resistant, making them suitable for hot-fill applications, and they have excellent barrier properties, which help to preserve the freshness and quality of packaged products. Furthermore, the biodegradable nature of Pla molded parts ensures that they do not contribute to the accumulation of plastic waste in landfills and oceans.The launch of the new line of Pla molded parts represents a significant milestone for Pla Molded Parts Company in its commitment to sustainable packaging solutions. The company has invested heavily in research and development to create a range of products that meet the growing demand for environmentally friendly packaging options. By offering a viable alternative to traditional plastics, Pla Molded Parts Company is helping its customers reduce their environmental footprint and meet their sustainability goals."We are excited to introduce our new line of Pla molded parts, which represents a major advancement in sustainable packaging technology," said the CEO of Pla Molded Parts Company. "Our team has worked tirelessly to develop a product that not only meets the performance requirements of our customers but also aligns with our mission of environmental responsibility. We believe that the market is ripe for eco-friendly packaging solutions, and our Pla molded parts offer a compelling option for businesses looking to make a positive impact on the planet."The launch of the new line of Pla molded parts also underscores Pla Molded Parts Company's ongoing commitment to innovation and quality. The company has a state-of-the-art manufacturing facility equipped with the latest technology and production processes, enabling it to deliver high-quality products that meet the needs of its customers. Furthermore, Pla Molded Parts Company has a team of experienced engineers and designers who work closely with clients to develop customized solutions that address specific packaging challenges."We take great pride in our ability to deliver innovative and sustainable packaging solutions to our customers," said the CEO. "Our new line of Pla molded parts is a testament to our dedication to pushing the boundaries of what is possible in the packaging industry. We are confident that this product will not only meet the needs of our clients but also make a positive impact on the environment."As the demand for environmentally friendly packaging continues to grow, Pla Molded Parts Company is well-positioned to capitalize on this trend with its new line of Pla molded parts. The company's unwavering commitment to sustainability and innovation has cemented its reputation as a leader in the industry, and its latest product launch is further evidence of its dedication to providing cutting-edge solutions to its customers.In conclusion, the launch of the new line of Pla molded parts by Pla Molded Parts Company represents a significant step forward in the quest for sustainable packaging solutions. With its eco-friendly and high-performance properties, these molded parts offer a compelling alternative to traditional plastics, and they are poised to make a positive impact on the environment. As businesses and consumers increasingly prioritize sustainability, Pla Molded Parts Company's latest offering is well-positioned to meet the growing demand for environmentally friendly packaging solutions.

Advanced Laser Prototyping for Rapid Product Development

Laser Prototyping Technology Revolutionizes Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, staying ahead of the curve and embracing cutting-edge technologies is essential for success. One such technology that is making waves in the industry is laser prototyping.Laser prototyping, also known as laser sintering or 3D printing, is a revolutionary manufacturing technique that uses a high-powered laser to selectively sinter powdered material into a three-dimensional object. This process enables the creation of complex and intricate parts with a high level of precision and accuracy, making it ideal for a wide range of industries including aerospace, automotive, medical, and consumer goods.One company that is at the forefront of laser prototyping technology is {}, a leading provider of advanced manufacturing solutions. With a strong focus on innovation and a commitment to pushing the boundaries of what is possible in manufacturing, {} has established itself as a key player in the industry.The company's state-of-the-art laser prototyping machines are capable of producing high-quality parts with exceptional mechanical properties and surface finish. By leveraging the power of laser technology, {} is able to deliver parts that meet the rigorous demands of modern manufacturing, helping its clients stay ahead of the competition.One of the key advantages of laser prototyping is its ability to rapidly iterate and iterate on designs, allowing for faster product development cycles. Traditional manufacturing methods often require lengthy lead times and costly tooling, but laser prototyping enables companies to quickly test and refine their designs, leading to faster time-to-market and reduced development costs.In addition to its speed and flexibility, laser prototyping also offers environmental benefits. By using only the exact amount of material needed to create a part, this technology minimizes waste and reduces the environmental impact of manufacturing processes. As sustainability becomes an increasingly important factor for businesses, laser prototyping offers a compelling solution for reducing carbon footprint and resource consumption.One of the most promising applications for laser prototyping is in the aerospace industry, where the demand for lightweight, high-performance parts is constantly growing. By utilizing advanced materials and intricate geometries, laser prototyping is enabling companies to push the boundaries of what is possible in aerospace design, resulting in more efficient and cost-effective aircraft.In the medical field, laser prototyping is being used to create custom implants and devices that are tailored to individual patient needs. With the ability to produce complex and patient-specific parts, this technology is revolutionizing the way medical devices are designed and manufactured, leading to improved patient outcomes and a higher standard of care.The automotive industry is also benefiting from laser prototyping, as companies seek to reduce weight and improve fuel efficiency in vehicles. By using advanced materials and design techniques made possible by laser prototyping, manufacturers are able to create lightweight and durable components that contribute to more sustainable and efficient transportation solutions.As the demand for laser prototyping technology continues to grow, {} is committed to staying at the forefront of this rapidly evolving field. By investing in research and development and collaborating with industry leaders, the company is poised to continue driving innovation and pushing the boundaries of what is possible in manufacturing.In conclusion, laser prototyping technology is revolutionizing the manufacturing industry by offering a faster, more efficient, and sustainable approach to producing high-quality parts. As companies like {} continue to push the boundaries of what is possible with this technology, it is clear that laser prototyping will play a vital role in shaping the future of manufacturing. With its ability to create complex and intricate parts with exceptional precision, laser prototyping is truly changing the game for the industry.