Benefits of Using Flexible Plastic Molding for Your Business

By:Admin

Founded in 2005, Flexible Plastic Molding has quickly risen to prominence in the industry, thanks to their state-of-the-art facilities, cutting-edge technology, and team of experienced professionals. The company's headquarters, located in the heart of the manufacturing district, houses a large inventory of injection molding machines, robotic assembly systems, and quality control equipment, allowing them to meet the diverse needs of their clients.

The company offers a wide range of manufacturing services, including design assistance, mold building, injection molding, assembly, and packaging. This comprehensive approach to manufacturing allows Flexible Plastic Molding to support their clients through every stage of the production process, from initial concept to final product.

One of the key differentiators for Flexible Plastic Molding is their ability to work with a variety of materials, including high-temperature thermoplastics, engineering-grade resins, and elastomers. This flexibility allows them to accommodate a wide range of project requirements, from simple consumer goods to complex industrial components.

In addition to their injection molding capabilities, Flexible Plastic Molding also provides value-added services such as insert molding, overmolding, and secondary operations. This holistic approach to manufacturing sets them apart from their competitors, as it allows them to deliver fully finished products that are ready for immediate use.

The company's commitment to quality is evident in their ISO 9001:2015 certification, which ensures that they adhere to the highest standards of operation and production. This certification, combined with their advanced quality control processes, allows Flexible Plastic Molding to consistently deliver products that meet or exceed their clients' expectations.

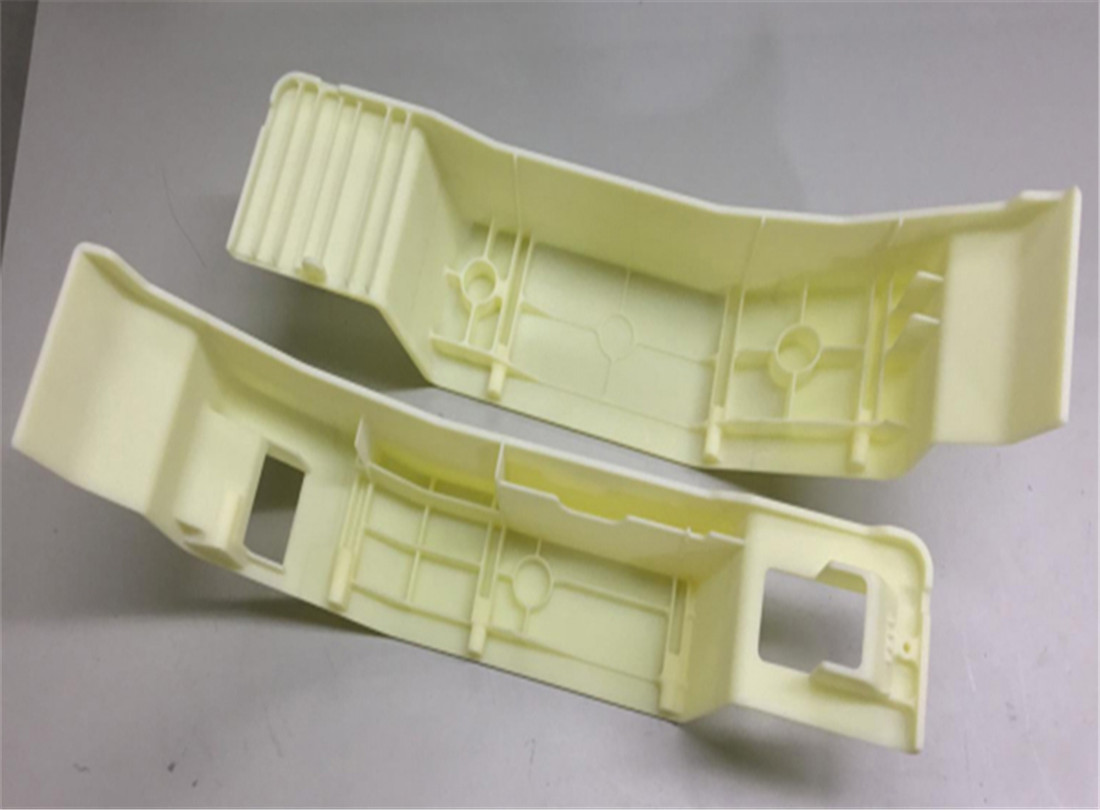

One of the company's recent success stories involves a partnership with a leading automotive manufacturer. The client approached Flexible Plastic Molding with a complex project that required the production of a series of precision-engineered components for their latest vehicle model. Thanks to their expertise in high-precision molding and their dedication to meeting tight tolerances, Flexible Plastic Molding was able to deliver the components on time and within budget, earning praise from the client for their exceptional quality and service.

Looking towards the future, Flexible Plastic Molding is poised for continued growth and success, as they continue to invest in new technologies and expand their capabilities. With a focus on innovation and continuous improvement, the company is well-positioned to meet the evolving needs of their clients and the industry as a whole.

In conclusion, Flexible Plastic Molding has established themselves as a go-to partner for businesses in need of custom plastic injection molding solutions. With a strong commitment to quality, service, and reliability, as well as a comprehensive range of manufacturing services and capabilities, the company is well-equipped to take on projects of any size and complexity. As they continue to push the boundaries of what is possible in plastic molding, Flexible Plastic Molding is set to remain a leader in the industry for years to come.

Company News & Blog

Ultimate Guide to Fast Prototyping: Everything You Need to Know

The 3D printing revolution has arrived, and with it comes the opportunity for companies to revolutionize their prototyping processes. [Company] is at the forefront of this movement, using cutting-edge technology to provide fast prototyping solutions that are changing the game for businesses around the world.Fast prototyping has become essential in the product development process, allowing companies to quickly iterate and test their ideas before going to market. Traditional prototyping methods are often time-consuming and costly, but [Company] has streamlined the process with their innovative 3D printing technology.[Company] was founded on the principle of making prototyping more accessible and efficient for businesses of all sizes. Their state-of-the-art facilities are equipped with the latest 3D printing technology, allowing them to create high-quality prototypes in a fraction of the time it would take with traditional methods. This has enabled companies to bring their ideas to life faster than ever before, giving them a competitive edge in their respective industries.The benefits of fast prototyping are clear. By being able to quickly produce and test prototypes, businesses can significantly reduce their time to market. This gives them the agility to respond to market trends and consumer demands in real-time, ultimately leading to greater success. In addition, fast prototyping allows for more iterations and improvements to be made in a shorter amount of time, resulting in better final products.One of the key advantages of partnering with [Company] for fast prototyping is their ability to produce prototypes with a high level of accuracy and detail. Their 3D printing technology allows for precise reproduction of even the most intricate designs, ensuring that the final product will meet the exact specifications of the original concept. This level of precision is invaluable in the product development process, as it allows for thorough testing and refinement of the prototype.Furthermore, [Company] offers a wide range of materials for fast prototyping, catering to the diverse needs of their clients. Whether it's plastic, metal, or even composite materials, [Company] has the capabilities to produce prototypes that meet the specific requirements of any project. This flexibility has made them a go-to partner for businesses in various industries, from automotive and aerospace to consumer electronics and healthcare.In addition to their technical capabilities, [Company] is committed to providing exceptional customer service and support throughout the fast prototyping process. Their team of experienced engineers and designers work closely with clients to understand their needs and provide tailored solutions that exceed expectations. From concept development to final prototype delivery, [Company] is dedicated to ensuring a seamless and successful experience for their clients.The future of fast prototyping with [Company] looks promising, as they continue to push the boundaries of what is possible with 3D printing technology. They are constantly investing in research and development to improve their processes and offer even more advanced solutions to their clients. This commitment to innovation has positioned [Company] as a leader in the fast prototyping industry, and they are poised to continue making a significant impact in the years to come.For businesses looking to accelerate their product development process and stay ahead of the competition, fast prototyping with [Company] is the answer. With their unparalleled expertise, state-of-the-art technology, and dedication to customer satisfaction, [Company] is the partner of choice for companies seeking to revolutionize their prototyping processes.

Discover the Benefits of CNC Rapid Prototyping for Your Business

CNC Rapid Prototyping: Revolutionizing the Manufacturing ProcessIn today's fast-paced world, the demand for innovative and efficient manufacturing processes is at an all-time high. With the rise of technology and consumer expectations, companies are constantly seeking new ways to improve their production methods. One such innovation that is making waves in the manufacturing industry is CNC Rapid Prototyping.CNC Rapid Prototyping, or Computer Numerical Control Rapid Prototyping, is a cutting-edge manufacturing process that utilizes computer-controlled machines to create high-quality prototypes and production parts. This revolutionary technology allows for quick and precise production of parts and products, significantly reducing lead times and costs associated with traditional manufacturing methods.One company that has been at the forefront of this technological revolution is {}. With over 20 years of experience in the manufacturing industry, {} has established itself as a leader in CNC Rapid Prototyping and has been instrumental in driving the adoption of this innovative technology in various industries.{}'s state-of-the-art facility is equipped with the latest CNC machines and advanced software, allowing them to produce complex parts with unmatched precision and speed. Their team of highly skilled engineers and technicians work closely with clients to understand their specific requirements and provide customized solutions that meet their exact needs.The benefits of CNC Rapid Prototyping are numerous. Not only does it allow for faster production and shorter lead times, but it also enables rapid iteration and refinement of designs, leading to greater innovation and product development. Additionally, the technology can be utilized to produce one-off prototypes or large production runs, providing flexibility to manufacturers and businesses of all sizes.The versatility of CNC Rapid Prototyping makes it suitable for a wide range of industries, including automotive, aerospace, medical, consumer goods, and more. It has the potential to revolutionize the way products are designed, developed, and manufactured across various sectors, ultimately driving efficiency and competitiveness in the global market.As the demand for CNC Rapid Prototyping continues to grow, {} remains committed to staying ahead of the curve and delivering cutting-edge solutions to its clients. With a focus on continuous innovation and investment in technology, the company is well-positioned to capitalize on the opportunities presented by this game-changing manufacturing process.In addition to their expertise in CNC Rapid Prototyping, {} also offers a range of complementary services, including design and engineering support, material selection, finishing options, and quality control measures. This comprehensive approach ensures that clients receive a seamless experience from concept to delivery, with the highest level of quality and reliability.With their dedication to excellence and a track record of success, {} is poised to lead the way in driving the widespread adoption of CNC Rapid Prototyping and shaping the future of manufacturing. As industries continue to evolve and embrace advanced technologies, companies like {} will play a pivotal role in fueling growth and innovation.In conclusion, CNC Rapid Prototyping is a game-changer in the manufacturing industry, and {} is at the forefront of this technological revolution. Their commitment to excellence, innovation, and customer satisfaction positions them as a trusted partner for businesses seeking to leverage the benefits of rapid prototyping and take their products to the next level. As the industry continues to evolve, the potential for CNC Rapid Prototyping to redefine manufacturing processes and drive unprecedented efficiency and innovation is limitless.

Unlocking Innovation: A Comprehensive Guide to Prototype Molds for Effective Product Development

Prototype Molds: Pioneering the Future of 3D Printing[City Name], [Date] - Prototype Molds, a leading player in the field of additive manufacturing and 3D printing, is revolutionizing the way products are designed and manufactured. With cutting-edge technology, a dedication to innovation, and a commitment to customer satisfaction, Prototype Molds is leading the way towards a future where 3D printing is the norm.Introduction:Prototype Molds, founded in [Year], has been at the forefront of additive manufacturing for over a decade. The company offers a wide range of services including rapid prototyping, 3D printing, and injection molding. With a team of skilled engineers, designers, and technicians, Prototype Molds has established itself as a go-to partner for companies looking to bring their ideas to life.Innovation in Additive Manufacturing:As one of the pioneers in the field of 3D printing, Prototype Molds has consistently pushed the boundaries of what is possible in manufacturing. Their state-of-the-art facility is equipped with the latest 3D printing technologies, allowing them to produce complex parts and prototypes with unparalleled precision. They have invested heavily in research and development, constantly striving to enhance the capabilities of their machines and processes.One major breakthrough by Prototype Molds is the development of high-performance materials for 3D printing. Through in-house research and partnerships with material suppliers, they have created a diverse range of materials that can meet the requirements of various industries, including aerospace, automotive, medical, and consumer electronics. These materials are not only durable and lightweight but also possess excellent mechanical properties, making them ideal for functional prototypes and end-use parts.Customer-Centric Approach:Prototype Molds understands the importance of customer satisfaction and collaboration. They work closely with clients from the initial design phase all the way through to the production of the final product. By involving clients at every step of the process, Prototype Molds ensures that their expectations are met, and the end result is a high-quality product that aligns with their vision.The company provides efficient and cost-effective solutions, allowing clients to bring their designs to market in a fraction of the time compared to traditional manufacturing methods. This significantly reduces development costs and gives companies a competitive edge in the fast-paced world of product innovation. Prototype Molds also offers expertise in design optimization, helping clients streamline their products for better performance and manufacturability.Continuous Growth and Expansion:Prototype Molds has experienced rapid growth and success in recent years, expanding its operations to serve a global clientele. The company's reputation for delivering exceptional quality and its commitment to innovation have attracted clients from a wide range of industries, including Fortune 500 companies and startups alike.To meet the increasing demand for its services, Prototype Molds has recently invested in expanding its production capabilities and adding new machines. This expansion allows them to handle larger projects, cater to more clients simultaneously, and maintain quick turnaround times without compromising on quality.Community Engagement and Environmental Responsibility:Prototype Molds recognizes the importance of giving back to the community and being environmentally responsible. The company actively engages in various initiatives to support local schools and educational institutions, fostering an interest in STEM education and empowering the next generation of innovators. Additionally, they have implemented sustainable practices in their manufacturing processes, reducing waste and minimizing their carbon footprint.Conclusion:Prototype Molds continues to push the boundaries of what is achievable in additive manufacturing, revolutionizing the way products are designed and manufactured. With their commitment to innovation, customer satisfaction, and environmental responsibility, they are well-positioned to lead the way towards a future where 3D printing is the norm. As the industry evolves, Prototype Molds will undoubtedly remain at the forefront, driving innovation and shaping the future of additive manufacturing.

Rapid Prototype CNC Machining: Everything You Need to Know

CNC Machining Rapid Prototype service has become an essential part of modern production processes as companies strive to bring their products to market at an accelerated pace. With the increasing demand for high-quality prototypes in a short amount of time, manufacturing companies are turning to advanced CNC machining techniques to achieve their goals.The use of CNC (Computer Numerical Control) machining has revolutionized the way prototypes are developed, allowing for precise and efficient production of complex parts and components. By utilizing advanced CAD/CAM software, CNC machines can produce high-quality prototypes with unmatched accuracy and consistency.One company at the forefront of this rapid prototyping revolution is {}. They have developed a reputation as a leading provider of CNC machining services, offering a wide range of capabilities to meet the diverse needs of their clients. With state-of-the-art equipment and a team of skilled technicians, they are able to deliver rapid prototypes with exceptional precision and speed.From concept to completion, {} works closely with their clients to understand their unique requirements and provide customized solutions. With a focus on quality and efficiency, they have established themselves as a trusted partner for companies in various industries, including aerospace, automotive, medical, and consumer electronics.By leveraging the latest CNC machining technologies, {} is able to produce prototypes that closely mimic the final production parts, allowing their clients to conduct thorough testing and validation before moving into full-scale production. This level of accuracy and attention to detail has helped their clients reduce development time and costs, ultimately giving them a competitive edge in their respective markets.In addition to their rapid prototyping services, {} offers a range of complementary capabilities, including CNC milling, turning, and EDM (Electrical Discharge Machining). This comprehensive suite of services enables them to handle a wide variety of projects, from simple components to complex assemblies, all while maintaining the highest quality standards.With a commitment to continuous improvement, {} regularly invests in the latest CNC machining equipment and technology to stay ahead of the curve. Their dedication to staying at the forefront of innovation has cemented their position as a leader in the rapid prototyping industry, earning the trust and loyalty of their clients.As the demand for rapid prototyping continues to grow, {} remains committed to meeting the evolving needs of their clients. By staying true to their core values of quality, precision, and customer satisfaction, they are poised to remain a key player in the CNC machining industry for years to come.In conclusion, rapid prototyping has become an indispensable tool for companies looking to bring their products to market quickly and efficiently. With the advanced capabilities of CNC machining, companies like {} are able to provide high-quality prototypes with unmatched speed and precision, helping their clients stay ahead of the competition. As technology continues to advance, the future of rapid prototyping looks brighter than ever, with endless possibilities for innovation and efficiency.

Effective Ways to Cut Styrofoam for Your DIY Projects

Innovative Styrofoam Cutting Technology Revolutionizes Packaging IndustryIn today's rapidly evolving world, the need for sustainable and efficient packaging solutions has never been more critical. Thankfully, companies like {} are stepping up to the plate with innovative technologies that are revolutionizing the packaging industry. One such technology that is making waves is their state-of-the-art Styrofoam cutting technology, which is not only environmentally friendly but also provides superior performance compared to traditional packaging materials.The traditional method of cutting Styrofoam involves using hot wires or knives, which can be slow, imprecise, and generate a significant amount of waste. However, {} has developed a cutting-edge solution that addresses these issues and sets a new standard for Styrofoam processing. Their cutting technology utilizes advanced machinery and software to precisely cut and shape Styrofoam with speed and efficiency, while minimizing waste and energy consumption.One of the key advantages of {}'s Styrofoam cutting technology is its versatility. The machinery can be programmed to cut Styrofoam into a wide range of shapes and sizes, making it ideal for custom packaging applications. This level of flexibility allows companies to create packaging solutions that perfectly fit their products, reducing the need for excess materials and minimizing the overall environmental impact.In addition to its versatility, {}'s cutting technology also boasts impressive precision and speed. With the ability to cut complex designs with pinpoint accuracy, companies can achieve a level of consistency and quality that is simply unattainable with traditional cutting methods. Furthermore, the efficiency of the machinery ensures that production times are significantly reduced, allowing businesses to meet tight deadlines without compromising on quality.Perhaps the most significant benefit of {}'s Styrofoam cutting technology is its environmental impact. Traditional Styrofoam cutting methods are notorious for generating a substantial amount of waste, as well as consuming large amounts of energy. In contrast, {}'s cutting technology is designed to minimize waste and energy consumption, making it a much more sustainable option for companies looking to reduce their environmental footprint. By utilizing this cutting-edge technology, businesses can align themselves with the growing demand for eco-friendly packaging solutions and demonstrate their commitment to environmental stewardship.{}'s commitment to sustainability doesn't stop at their cutting technology. The company as a whole is dedicated to reducing its environmental impact and continuously seeks out innovative solutions to achieve this goal. From sourcing eco-friendly materials to implementing energy-efficient practices in their manufacturing processes, {} is leading the charge toward a more sustainable future for the packaging industry.Furthermore, {}'s dedication to innovation extends beyond their cutting technology. They are continually investing in research and development to explore new ways to enhance their products and processes, ensuring that they remain at the forefront of technological advancements in the industry. By staying ahead of the curve, {} is able to provide its customers with cutting-edge solutions that not only meet but exceed their needs and expectations.In conclusion, {}'s Styrofoam cutting technology represents a significant milestone in the packaging industry. By offering a versatile, precise, and sustainable solution for cutting Styrofoam, the company is empowering businesses to elevate their packaging capabilities and reduce their environmental impact. With a steadfast commitment to innovation and sustainability, {} is poised to lead the way in shaping a greener and more efficient future for the packaging industry.

Custom Silicone Rubber Molding Services for Your Products

Silicone rubber molding is a popular manufacturing process that involves the use of silicone rubber to shape and create various products and components. This versatile and durable material is used in a wide range of industries, including automotive, medical, and consumer goods. The process of silicone rubber molding allows for the production of complex and intricate parts that are difficult or impossible to create using other manufacturing methods.One company that has been at the forefront of silicone rubber molding technology is {}. With over 20 years of experience in the industry, {} has established itself as a leader in the production of silicone rubber molded products. The company prides itself on its commitment to quality, innovation, and customer satisfaction, and has a proven track record of delivering high-quality silicone rubber molded components to its clients.{} offers a comprehensive range of silicone rubber molding services, including custom mold design and fabrication, silicone material selection and formulation, precision molding and finishing, as well as testing and validation. The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and technology to ensure the highest level of precision and efficiency in the production process.In addition to its technical capabilities, {} also emphasizes the importance of collaboration and partnership with its clients. The company works closely with customers to understand their specific needs and requirements, and provides tailored solutions to meet their unique challenges. Whether it's a small-scale prototype or a large-scale production run, {} has the expertise and resources to deliver reliable and cost-effective silicone rubber molded products.One of the key advantages of silicone rubber molding is its ability to create parts with exceptional precision and consistency. The process allows for the production of intricate and complex geometries, making it ideal for applications that require high levels of accuracy and detail. With its expertise in mold design and fabrication, {} is able to produce molds that capture even the most intricate features of a part, ensuring a high level of precision and repeatability in the molding process.Another benefit of silicone rubber molding is the material's durability and performance. Silicone rubber is known for its resilience and resistance to extreme temperatures, chemicals, and environmental factors, making it an ideal choice for a wide range of applications. Whether it's for automotive gaskets, medical devices, or consumer electronics, silicone rubber molded components from {} are designed to withstand the harshest conditions and deliver reliable performance over an extended period of time.Furthermore, silicone rubber molding offers high levels of customization and flexibility, allowing for the production of unique and specialized parts. {} works closely with its clients to understand their specific requirements and to develop customized solutions that meet their exact needs. With its extensive knowledge of silicone materials and molding processes, the company is able to offer a wide range of options in terms of material properties, colors, and finishes, allowing for the creation of truly bespoke products.In conclusion, silicone rubber molding is a versatile and reliable manufacturing process that has numerous benefits for a wide range of industries. {} has positioned itself as a leading provider of silicone rubber molded components, offering a comprehensive range of services and a commitment to quality and customer satisfaction. With its extensive expertise, advanced technology, and dedication to collaboration, {} is well-equipped to meet the growing demand for high-quality silicone rubber molded products in the global market.

Advanced Aluminum Injection Molding: The Future of Manufacturing

Aluminum injection molding is revolutionizing the manufacturing industry, and {} is at the forefront of this innovative technology. With years of experience and a commitment to delivering high-quality products, the company is leading the way in the aluminum injection molding industry.{} has been a key player in the manufacturing industry for over a decade, specializing in the production of a wide range of precision components for various industries, including automotive, aerospace, electronics, and more. With a state-of-the-art facility and a team of experienced engineers and technicians, the company has earned a reputation for excellence and reliability.The introduction of aluminum injection molding has allowed {} to take their production capabilities to the next level. This advanced manufacturing process offers numerous advantages over traditional methods, including faster cycle times, enhanced design flexibility, and improved part quality and consistency. As a result, {} is able to produce complex aluminum components with tight tolerances and intricate geometries that were once thought impossible to achieve.One of the key benefits of aluminum injection molding is its ability to produce lightweight yet durable components. This is particularly important in industries such as automotive and aerospace, where weight reduction is a critical factor in improving fuel efficiency and overall performance. With aluminum injection molding, {} is able to manufacture components that are not only lighter in weight but also highly resistant to corrosion, making them ideal for a wide range of applications.In addition to its lightweight properties, aluminum injection molding also offers significant cost savings compared to traditional manufacturing methods. By reducing material waste and minimizing the need for secondary operations, {} is able to produce high-quality aluminum components at a lower cost, helping their customers improve their bottom line and stay competitive in the market.Furthermore, {} is committed to sustainability and environmental responsibility. Aluminum is highly recyclable, and the company ensures that any scrap generated during the injection molding process is properly recycled and reused, minimizing its impact on the environment.As a leader in the aluminum injection molding industry, {} is dedicated to staying at the forefront of technology and innovation. The company continues to invest in the latest equipment and training for its staff, ensuring that they are always able to meet the diverse needs of their customers and deliver the highest quality products.With a proven track record of excellence and a commitment to continuous improvement, {} has positioned itself as a trusted partner for businesses looking for superior aluminum injection molding solutions. Whether it's for prototyping, low-volume production, or high-volume manufacturing, {} has the expertise and capabilities to deliver exceptional results.In conclusion, aluminum injection molding is ushering in a new era of manufacturing, and {} is at the forefront of this exciting technology. With a dedication to quality, innovation, and customer satisfaction, the company continues to lead the industry, offering superior aluminum injection molding solutions for a wide range of applications. As the demand for lightweight, durable, and cost-effective components continues to grow, {} is well-equipped to meet the needs of its customers and drive the industry forward.

Top Tips for Plastic Injection Moulding

Plastic Injection Mould Technology Revolutionizes Manufacturing: A Look into the Innovative Solutions by [Company Name]In today's fast-paced world, manufacturing industries are constantly evolving and adapting to meet the demands of consumers. One company at the forefront of this revolution is [Company Name]. With their cutting-edge plastic injection mould technology, they have been able to provide innovative solutions for various industries.[Company Name] has been in the business for over two decades, and their expertise in plastic injection mould technology has made them a formidable force in the manufacturing industry. The company has consistently delivered high-quality products, and their commitment to innovation has allowed them to stay ahead of the competition.The plastic injection mould technology used by [Company Name] allows for the production of complex and intricate parts with high precision and efficiency. This technology has enabled the company to cater to a wide range of industries, from automotive to consumer electronics and medical devices.One of the key advantages of plastic injection mould technology is its versatility. It can be used to create a wide variety of products ranging from small, intricate parts to large components. This flexibility has allowed [Company Name] to serve a diverse clientele and meet the unique needs of each industry.Furthermore, the company's dedication to sustainability is evident in their manufacturing processes. By utilizing plastic injection mould technology, they are able to minimize material waste and energy consumption, thus reducing their environmental impact. This commitment to sustainability has not only benefited the environment but has also allowed the company to offer cost-effective solutions to their clients.In addition to their advanced technology, [Company Name] also prides itself on its team of highly skilled and experienced professionals. The company's engineers and technicians are well-versed in the latest developments in plastic injection mould technology, and they are able to deliver innovative solutions to even the most challenging manufacturing projects.One of the most notable achievements of [Company Name] is their recent collaboration with a leading automotive manufacturer. The company was able to design and manufacture a complex plastic component for the automotive industry using their state-of-the-art plastic injection mould technology. This collaboration not only showcased the company's technical expertise but also solidified their position as a trusted partner for the automotive industry.Looking ahead, [Company Name] is committed to staying at the forefront of plastic injection mould technology. The company is constantly investing in research and development to further enhance their manufacturing capabilities and provide even more innovative solutions for their clients.In conclusion, [Company Name] has proven to be a trailblazer in the manufacturing industry with their advanced plastic injection mould technology. Their dedication to innovation, sustainability, and quality has set them apart as a leader in the field. With their continued commitment to excellence, [Company Name] is poised to revolutionize the manufacturing industry for years to come.

The Importance of Rapid Prototyping and Rapid Tooling in the Manufacturing Industry

Rapid Prototyping And Rapid Tooling, also known as 3D printing, have revolutionized the manufacturing industry in recent years. This cutting-edge technology allows businesses to create prototypes and tools quickly and cost-effectively, leading to streamlined production processes and faster time-to-market for new products. With the increasing demand for rapid prototyping and rapid tooling solutions, companies are turning to innovative industry leaders like {} to meet their manufacturing needs.{} is a leading provider of rapid prototyping and rapid tooling solutions, offering a wide range of services to help businesses bring their ideas to life. With state-of-the-art equipment and a team of highly skilled engineers and designers, {} has the capabilities to turn concepts into fully functional prototypes in a matter of days. Their innovative approach to manufacturing has helped countless businesses save time and money while bringing their products to market faster than ever before.One of the key advantages of rapid prototyping and rapid tooling is the ability to quickly iterate and refine designs. Traditional manufacturing methods can be time-consuming and costly, making it difficult for businesses to make changes to their products once they are in the production phase. However, with rapid prototyping, businesses can easily make modifications to their designs and test them out in real-world scenarios, allowing for greater innovation and improved product quality.In addition to rapid prototyping, {} also specializes in rapid tooling, which involves creating molds and other production tools using 3D printing technology. This allows businesses to quickly and cost-effectively produce tools that are customized to their specific manufacturing needs, further streamlining the production process and reducing lead times. By leveraging the power of rapid tooling, businesses can bring new products to market faster and more efficiently than ever before.The team at {} understands the complexities of the manufacturing industry and works closely with their clients to ensure that their unique needs are met. They offer a range of materials and finishing options to accommodate various product requirements, and their expertise in rapid prototyping and rapid tooling allows them to tackle even the most challenging projects with ease.With the increasing demand for rapid prototyping and rapid tooling solutions, {} has positioned themselves as a go-to source for businesses looking to streamline their manufacturing processes and bring new products to market quickly. Their commitment to innovation and quality has earned them a reputation as an industry leader, and their dedication to customer satisfaction has resulted in numerous successful partnerships with businesses across a wide range of industries.As technology continues to advance, the demand for rapid prototyping and rapid tooling solutions will only continue to grow. Businesses are constantly looking for ways to improve their production processes and bring new products to market faster, and companies like {} are at the forefront of this exciting industry. With their expertise and state-of-the-art facilities, {} is well-equipped to meet the evolving needs of businesses in an increasingly complex and competitive global marketplace.

Durable and Flexible Rubber Chain Cover for Improved Protection

The rubber industry is ever-evolving, with companies continually striving to provide innovative solutions for their customers. One such company that has been making waves in the industry is [Company Name], a leading manufacturer of rubber products. Recently, they have announced the launch of their latest product, Chain Cover Rubber, which is set to revolutionize the market.[Company Name] has been in the rubber manufacturing industry for over three decades, specializing in producing high-quality rubber products that cater to a wide range of applications. With a strong focus on research and development, the company has consistently introduced innovative products that have set new benchmarks in the industry.The Chain Cover Rubber is the latest addition to their extensive product portfolio, and it promises to deliver exceptional performance in various industrial applications. This product has been specifically designed to provide superior protection for chains, ensuring smooth operation and longevity. The rubber material used in the Chain Cover Rubber is known for its durability and resistance to wear and tear, making it an ideal choice for demanding environments.One of the key features of the Chain Cover Rubber is its ability to withstand harsh conditions, including extreme temperatures and corrosive chemicals. This makes it suitable for use in a wide range of industries, including manufacturing, mining, agriculture, and construction. The product is also designed to be highly flexible, allowing for easy installation and maintenance, further enhancing its appeal to customers.In addition to its impressive performance capabilities, the Chain Cover Rubber also meets the highest quality standards, ensuring reliability and consistency. [Company Name] is committed to maintaining stringent quality control measures throughout the manufacturing process, ensuring that their products meet or exceed industry standards. As a result, customers can have peace of mind knowing that they are investing in a product that is built to last.Furthermore, [Company Name] takes pride in its commitment to sustainability and environmental responsibility. The materials used in the production of the Chain Cover Rubber are sourced ethically, and the manufacturing process adheres to strict environmental guidelines. This reflects the company's dedication to minimizing its impact on the environment while delivering top-notch products to its customers.The launch of the Chain Cover Rubber is a significant milestone for [Company Name], demonstrating its continued dedication to innovation and customer satisfaction. As the demand for high-quality rubber products continues to grow, [Company Name] is well-positioned to meet the needs of its customers with this latest offering.The reception to the Chain Cover Rubber has been overwhelmingly positive, with early adopters praising its performance and reliability. Customers have lauded its ability to prolong the lifespan of their chains and reduce maintenance costs, ultimately leading to improved efficiency and cost savings.In light of the success of the Chain Cover Rubber, [Company Name] is already looking ahead to future innovations and product developments. The company remains committed to pushing the boundaries of rubber technology, with a focus on meeting the evolving needs of its customers across various industries.In conclusion, the launch of the Chain Cover Rubber marks an exciting new chapter for [Company Name] and the rubber industry as a whole. With its advanced features, exceptional performance, and dedication to quality and sustainability, the product is poised to become a game-changer in the market. As [Company Name] continues to set new standards for excellence, customers can expect to see more groundbreaking products that redefine the possibilities of rubber technology.