A Guide to Custom Metal Brackets: Uses and Applications

By:Admin

Custom Metal Brackets specializes in providing custom solutions for a wide range of industries, including automotive, construction, aerospace, and more. Their team of skilled engineers and designers work closely with clients to understand their requirements and provide them with tailored solutions that meet their exact specifications.

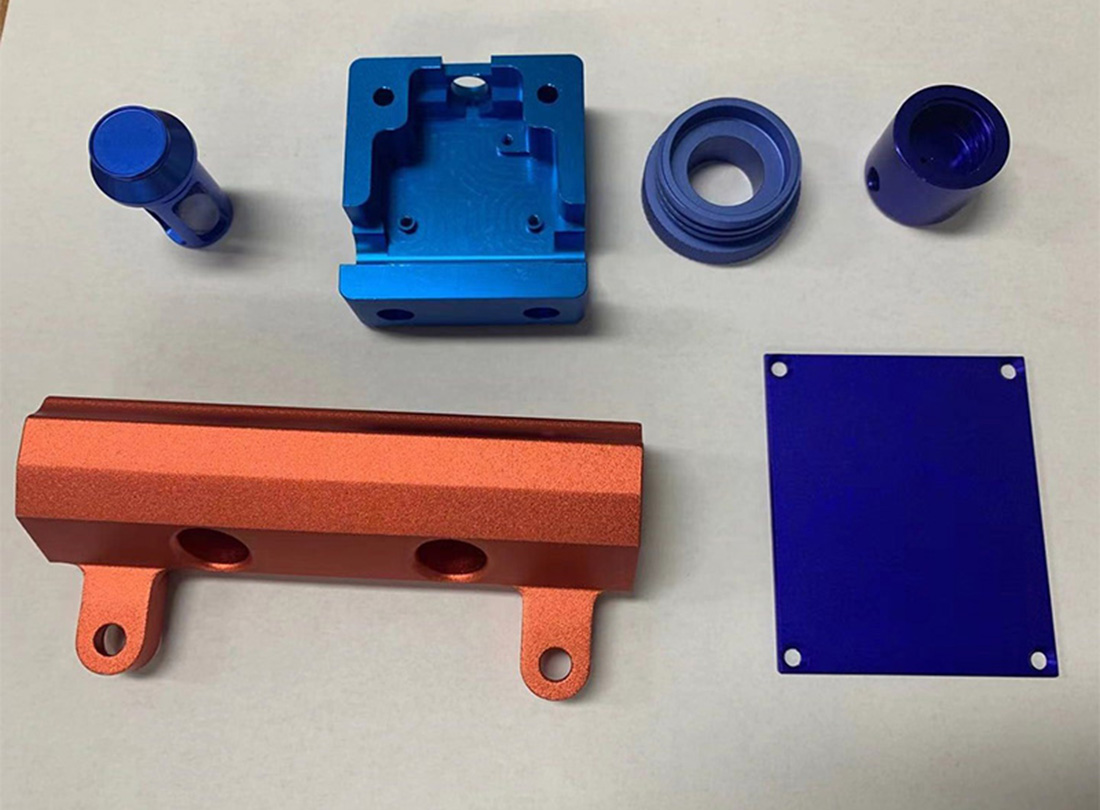

The new line of metal brackets features a range of customization options, including different sizes, shapes, materials, and finishes. This allows customers to create brackets that are perfectly suited to their specific applications, whether they are used for supporting heavy machinery, securing components in aerospace applications, or any other purpose.

One of the key features of Custom Metal Brackets' new line is the ability to provide quick turnaround times without compromising on quality. With their advanced manufacturing capabilities and state-of-the-art equipment, the company is able to deliver custom metal brackets with short lead times, helping their clients meet tight deadlines and stay ahead of the competition.

In addition to their customizable solutions, Custom Metal Brackets also places a strong emphasis on quality control and precision. Their team is committed to ensuring that every bracket they produce meets the highest standards of quality and accuracy, with thorough inspections and testing procedures in place to guarantee the reliability and performance of their products.

"We are excited to introduce our new line of customizable metal brackets to the market," said [Founder/CEO Name] of Custom Metal Brackets. "We understand the unique needs of our customers and are dedicated to providing them with the best possible solutions to help them succeed. With our new line, we aim to offer even greater flexibility and customization options to meet the diverse requirements of various industries."

Custom Metal Brackets' commitment to excellence extends beyond their products to their customer service and support. The company prides itself on maintaining strong relationships with their clients, offering personalized assistance, expert guidance, and ongoing technical support to ensure that their customers have a seamless experience from design to production.

With their new line of customizable metal brackets, Custom Metal Brackets aims to further solidify their position as a trusted and reliable partner for businesses in need of high-quality metal components. The company's dedication to innovation, precision, and customer satisfaction continues to set them apart in the industry and make them a go-to choice for custom metal brackets.

For more information about Custom Metal Brackets, their new line of customizable metal brackets, and how they can help businesses with their metal component needs, visit their website at [website URL].

Company News & Blog

Advanced Rapid Prototyping services for precision CNC Machining

Rapid Prototyping CNC Machining, a cutting-edge manufacturing process that is revolutionizing the industry, is now being offered by {} – a leading provider of precision machining solutions.With the increasing demand for customized and high-quality products, manufacturers are constantly seeking faster and more efficient ways to bring their designs from concept to reality. Rapid Prototyping CNC machining offers a solution to this challenge by allowing for the quick and accurate production of complex prototypes and parts.{} has been at the forefront of this technology, offering its clients access to state-of-the-art CNC machines that are capable of producing intricate and precise parts in a fraction of the time of traditional manufacturing methods. Leveraging the latest in CAD/CAM software, {} is able to rapidly design and manufacture prototypes and produce end-use parts that meet the highest standards of quality and precision.With its extensive experience and expertise in CNC machining, {} is able to offer a wide range of materials for rapid prototyping, including plastics, metals, and composites. This versatility allows customers to prototype and test their designs in a variety of materials, ensuring that the final product meets their requirements for performance and durability.In addition to rapid prototyping, {} also provides CNC machining services for larger production runs. Its advanced CNC machines are capable of producing high volumes of parts with consistent quality, making {} a one-stop shop for all of its clients' manufacturing needs.Furthermore, {}'s team of experienced engineers and technicians work closely with its clients throughout the entire manufacturing process, providing the expertise and support needed to bring their designs to life. Whether it's a complex prototype or a large production run, {} is committed to delivering superior quality and precision in every project it undertakes.The introduction of rapid prototyping CNC machining at {} demonstrates the company's commitment to staying at the forefront of technological advancements in the manufacturing industry. By investing in the latest equipment and software, {} is able to offer its clients an unmatched level of speed, precision, and flexibility in their manufacturing processes.With rapid prototyping CNC machining, {} is able to help its clients bring their products to market faster, reduce development costs, and ultimately gain a competitive edge in their respective industries. Whether it's for a new product development or an improvement on an existing design, {}'s rapid prototyping capabilities enable its clients to quickly iterate on their ideas and bring them to market with confidence.In conclusion, the introduction of rapid prototyping CNC machining at {} represents a significant advancement in the company's capabilities and a major benefit to its clients. By leveraging the latest in CNC technology and software, {} is able to offer its clients a level of speed, precision, and flexibility that is unmatched in the industry. With its commitment to delivering superior quality and precision in every project, {} is well-positioned to meet the evolving needs of its clients and drive innovation in the manufacturing industry.

Custom High Precision Machining Part for Precision Engineering Solutions

[Company Name], a leading provider of high precision machining parts, has recently announced the launch of its latest product, the [Product Name]. This new addition to their product line is expected to enhance the company's position as a key player in the high precision machining industry.The [Product Name] is a breakthrough in the field of high precision machining, offering unprecedented levels of accuracy and reliability. The product has been designed to meet the growing demand for high precision components in industries such as aerospace, automotive, medical devices, and defense.[Company Name] has always been at the forefront of innovation in the machining industry, and the development of the [Product Name] is a testament to their commitment to delivering the highest quality products to their customers. With state-of-the-art technology and a team of highly skilled engineers, the company has been able to achieve a level of precision that is unmatched in the industry.In addition to the [Product Name], [Company Name] offers a wide range of high precision machining parts, including components for CNC machines, lathes, milling machines, and more. Their products are known for their exceptional quality and durability, making them the top choice for companies looking for reliable and high-performance machining parts.With a strong focus on customer satisfaction, [Company Name] has built a reputation for providing exceptional service and support to their clients. Their team of experts is always available to answer any questions and provide technical assistance, ensuring that their customers have everything they need to achieve their machining goals.In addition to their commitment to quality and innovation, [Company Name] is also dedicated to sustainability and environmental responsibility. They have implemented rigorous measures to minimize their environmental impact, from recycling and waste reduction to energy-efficient manufacturing processes.As a result of their dedication to excellence, [Company Name] has gained a loyal customer base and has established strong partnerships with leading companies in various industries. Their products are trusted by some of the biggest names in aerospace, automotive, and medical device manufacturing, further solidifying their position as a key player in the high precision machining industry.The launch of the [Product Name] is a significant milestone for [Company Name], and it is expected to further strengthen their position in the market. With its unparalleled precision and reliability, the [Product Name] is set to become the go-to choice for companies looking for high quality machining parts.The [Product Name] is now available for purchase, and [Company Name] is offering special introductory deals for their customers. With its cutting-edge technology and exceptional performance, the [Product Name] is poised to revolutionize the high precision machining industry and set new standards for accuracy and reliability.For more information about the [Product Name] and other high precision machining parts offered by [Company Name], please visit their website or contact their customer service team.

High-Quality CNC Machined Components for Precision Engineering Needs

Precision CNC Machined Components: {Company Name} Leads the Industry with Superior Quality and InnovationIn the world of manufacturing, precision and accuracy are essential. The demand for high-quality CNC machined components is at an all-time high, and companies are continually striving to push the boundaries of what is possible. At the forefront of this industry is {Company Name}, a leading manufacturer of precision CNC machined components. With a proven track record of delivering superior quality and innovative solutions, {Company Name} has firmly established itself as a trailblazer in the field of CNC machining.With state-of-the-art facilities and a team of highly skilled engineers and technicians, {Company Name} is able to produce complex and intricate CNC machined components with unparalleled precision. The company's dedication to investing in the latest machining technology and equipment has allowed it to stay ahead of the curve, consistently delivering products that meet the highest standards of quality and reliability.One of the key factors that sets {Company Name} apart from its competitors is its unwavering commitment to innovation. The company's team of experts is constantly exploring new techniques and methodologies to improve the efficiency and performance of their CNC machining processes. This relentless pursuit of innovation has enabled {Company Name} to develop cutting-edge solutions that meet the evolving needs of the industry, ensuring that its customers receive the best possible products.In addition to its focus on innovation, {Company Name} places a strong emphasis on quality control. The company's rigorous quality assurance processes and procedures are designed to ensure that every CNC machined component that leaves its facility meets the strictest standards of excellence. By adhering to these high-quality standards, {Company Name} has earned a reputation for producing components that are both reliable and precise, making it the supplier of choice for many leading companies across various industries.{Company Name} serves a diverse range of industries, including aerospace, automotive, medical, and many others. Its ability to tailor its manufacturing processes to meet the specific requirements of each industry has made it a trusted partner for numerous companies looking for precision CNC machined components. Whether it's producing complex aerospace parts or critical components for medical devices, {Company Name} has the expertise and capabilities to deliver solutions that meet the highest industry standards.As the demand for precision CNC machined components continues to grow, {Company Name} is positioned to capitalize on this trend. With its unwavering dedication to quality, innovation, and customer satisfaction, the company is well-positioned to maintain its leadership in the industry. Moreover, its commitment to investing in the latest technology and equipment ensures that {Company Name} will continue to push the boundaries of what is possible in the world of CNC machining.Looking to the future, {Company Name} is poised for even greater success as it continues to expand its capabilities and explore new opportunities for growth. With a strong focus on customer collaboration and an ongoing commitment to excellence, the company is well-equipped to meet the evolving needs of the industry and provide its customers with the superior quality and innovative solutions they have come to expect.In conclusion, {Company Name} has firmly established itself as a leader in the field of precision CNC machined components. Its relentless pursuit of innovation, unwavering commitment to quality, and ability to tailor its solutions to meet the specific needs of each industry have set it apart as a trailblazer in the industry. As the demand for high-quality CNC machined components continues to rise, {Company Name} is well-positioned to meet this demand and maintain its position as a trusted partner for companies across various industries.

Unlocking the Potential of Rapid Tooling Injection Molding for Advanced Manufacturing

Title: Advancements in Rapid Tooling Injection Molding Streamline Manufacturing ProcessesIntroduction:In recent years, the manufacturing industry has witnessed remarkable advancements in technology, with rapid tooling injection molding emerging as a cutting-edge technique. This process allows for the production of high-quality prototype parts, reducing lead times and costs significantly. One prominent player in this field, [Company Name], has taken a leap forward with their innovative solutions and expertise in this domain. This article aims to delve into the world of rapid tooling injection molding and shed light on how [Company Name] is revolutionizing manufacturing processes.Rapid Tooling Injection Molding:Rapid tooling injection molding, also known as RTIM, is a manufacturing technique that combines traditional injection molding methods with rapid prototyping technologies. This process involves the production of tooling inserts using additive manufacturing techniques or subtractive processes like CNC machining. These inserts are then integrated into injection molds, enabling the mass production of high-quality plastic parts in a short period.By significantly reducing lead times, RTIM allows manufacturers to bring products to market faster, giving them a competitive edge. Additionally, this technique eliminates the need for expensive and time-consuming metal tooling, making it an attractive option for small-scale production runs, prototypes, and low-volume manufacturing.[Company Name]'s Innovative Solutions:[Company Name] is a leading player in the field of rapid tooling injection molding. With their expertise and dedication to innovation, they have developed a range of solutions that have wide-ranging applications across industries.1. Advanced Material Selection:[Company Name] understands the importance of selecting the right materials for each project. They offer a wide variety of thermoplastics and specialty materials, ensuring the utmost precision, durability, and functional performance in the final product. By leveraging their materials expertise, they can cater to diverse customer requirements, from medical-grade parts to aerospace components.2. Design Optimization:One of the significant advantages of rapid tooling injection molding is the ability to optimize designs quickly. [Company Name] employs design engineers who work closely with clients to enhance the manufacturability of their products. By utilizing advanced simulation techniques, they identify potential design flaws early in the process, reducing iterations and achieving higher quality end products efficiently.3. Automation and Robotics:To further enhance efficiency, [Company Name] leverages automation and robotics in their manufacturing processes. This integration streamlines operations, reducing human error and enhancing overall production output. The company's investment in cutting-edge automation technology ensures consistent, high-quality parts while maintaining cost-effectiveness.4. Quality Control and Testing:[Company Name] places utmost importance on quality control and testing throughout the manufacturing process. By employing stringent quality assurance protocols, including dimensional analysis, functionality testing, and surface finish inspections, they ensure that the final products meet or exceed industry standards. This commitment to quality has earned them a solid reputation among their clientele.Conclusion:Rapid tooling injection molding has revolutionized the manufacturing industry by enabling fast, cost-effective production of high-quality plastic parts. [Company Name], with its expertise and innovative solutions, has emerged as a key player in this field. Their commitment to material selection, design optimization, strategic automation, and rigorous quality control makes them an industry leader capable of meeting diverse customer requirements. As technology continues to evolve, it is exciting to witness the transformative impact rapid tooling injection molding, along with companies like [Company Name], is having on the manufacturing industry.

High Quality CNC Turned Components for Precision Machining

CNC Turned Components: The Backbone of Precision EngineeringIn the world of precision engineering, CNC turned components play a crucial role in the manufacturing process. These components are essential for a wide range of industries, including aerospace, automotive, medical, and consumer electronics. Their precision and reliability make them indispensable for the production of high-quality products.One of the leading manufacturers of CNC turned components is {}. With decades of experience in the industry, {} has established itself as a trusted supplier of high-precision components for various applications. The company's state-of-the-art facilities and advanced machinery enable it to produce components with exceptional accuracy and consistency.CNC turned components are produced using computer numerical control (CNC) machines, which are capable of performing intricate and complex machining operations with a high degree of precision. These machines are programmed to follow precise instructions to create the desired shape and dimensions of the components. This level of precision and repeatability is essential for meeting the stringent quality standards of modern manufacturing.{} offers a wide range of CNC turned components, including shafts, pins, connectors, and custom-designed parts. These components are manufactured using a variety of materials, such as aluminum, stainless steel, brass, and plastics, to meet the specific requirements of different industries. With a focus on quality and reliability, {} ensures that its components meet the highest standards and specifications, making them suitable for critical applications.The aerospace industry, in particular, relies heavily on CNC turned components for the production of aircraft engines, landing gear, and avionics systems. The demanding nature of aerospace applications necessitates the use of components that can withstand extreme conditions and operate with precision and efficiency. {} has a proven track record of supplying CNC turned components that meet the stringent requirements of the aerospace industry, earning the trust of major aerospace companies.In the automotive industry, CNC turned components are used in a wide range of applications, including engine components, transmission systems, and steering mechanisms. These components must meet strict tolerances and performance requirements to ensure the reliability and safety of automotive vehicles. {} has a strong presence in the automotive sector, providing high-quality CNC turned components that contribute to the performance and durability of vehicles.The medical industry also relies on CNC turned components for various applications, such as surgical instruments, medical devices, and diagnostic equipment. The precision and consistency of these components are critical for ensuring the accuracy and reliability of medical products. {} supplies CNC turned components that meet the stringent regulatory requirements of the medical industry, making them suitable for use in critical healthcare applications.In the consumer electronics sector, CNC turned components are used in the production of electronic devices, including smartphones, tablets, and laptops. These components play a vital role in the functionality and performance of electronic products, requiring high-precision manufacturing to meet the exacting standards of the consumer electronics industry. {} specializes in providing CNC turned components that meet the demanding requirements of consumer electronics manufacturers, contributing to the production of cutting-edge electronic devices.As a leading manufacturer of CNC turned components, {} is committed to upholding the highest standards of quality, precision, and reliability. The company's dedication to excellence and continuous improvement has earned it a reputation as a trusted supplier of high-precision components for a wide range of industries. With its advanced capabilities and uncompromising commitment to customer satisfaction, {} continues to be a driving force in the world of precision engineering.

High-Quality Custom EPDM Rubber Products for Various Applications

Custom EPDM Rubber Products Rubber Parts, a leading manufacturer of rubber products, has announced the launch of a new line of EPDM rubber parts designed to meet the diverse needs of their customers. This new line of products aims to provide superior quality, durability, and performance, making them ideal for a wide range of applications in various industries.EPDM (Ethylene Propylene Diene Monomer) rubber is a synthetic rubber that is known for its excellent resistance to heat, weathering, and ozone. It also has excellent electrical insulating properties, making it suitable for a wide range of applications, including automotive, construction, industrial, and HVAC industries.Custom EPDM Rubber Products Rubber Parts has been a pioneer in the rubber industry for over 20 years, and their expertise in manufacturing high-quality rubber products is well recognized in the market. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, the company is able to develop and produce custom EPDM rubber parts that meet the exact specifications and requirements of their customers.The new line of EPDM rubber parts includes a wide range of products such as EPDM rubber gaskets, seals, O-rings, and custom-molded parts. These products are designed to withstand extreme temperatures, chemicals, and environmental factors, making them ideal for use in demanding applications. Whether it's sealing HVAC systems, protecting electrical components, or providing insulation in automotive applications, Custom EPDM Rubber Products Rubber Parts has the right solution for any need.In addition to their superior performance, the EPDM rubber parts from Custom EPDM Rubber Products Rubber Parts also offer excellent longevity and resistance to degradation, ensuring a longer service life and reduced maintenance costs for their customers. The company's commitment to quality and customer satisfaction is reflected in the rigorous testing and quality control measures that are implemented at every stage of the manufacturing process to ensure that the products meet the highest standards.With the launch of this new line of EPDM rubber parts, Custom EPDM Rubber Products Rubber Parts aims to further strengthen its position as a leading provider of high-quality rubber products. The company is confident that their new line of products will provide significant value to their customers by meeting their specific requirements and delivering exceptional performance in diverse applications."We are excited to introduce our new line of EPDM rubber parts, which is the result of our continued commitment to innovation and excellence in the rubber industry," said a spokesperson for Custom EPDM Rubber Products Rubber Parts. "These products are a testament to our dedication to meeting the evolving needs of our customers and providing them with reliable solutions that deliver superior performance and durability."Custom EPDM Rubber Products Rubber Parts is dedicated to providing comprehensive support to their customers, offering expert guidance and assistance in selecting the right EPDM rubber parts for their specific applications. With a focus on customer satisfaction and a track record of delivering high-quality products, the company has earned the trust and loyalty of their customers across various industries.As the demand for high-quality EPDM rubber parts continues to grow, Custom EPDM Rubber Products Rubber Parts remains committed to staying ahead of the curve by investing in research and development and continuously improving their manufacturing processes to deliver innovative and reliable solutions that exceed customer expectations.With the launch of their new line of EPDM rubber parts, Custom EPDM Rubber Products Rubber Parts is poised to set new benchmarks for excellence in the rubber industry and solidify their position as a preferred supplier of custom rubber parts for a wide range of applications.

Essential Components for Efficient Bending Machines Revealed in Latest News Content

[Company Name] Introduces Innovative Bending Machine Parts for Enhanced Efficiency and Durability[City, Date] - [Company Name], a leading manufacturer and provider of industrial machinery, is pleased to announce its latest range of cutting-edge bending machine parts. Designed to meet the evolving needs of the manufacturing industry, these parts offer enhanced efficiency, durability, and precision, revolutionizing the process of bending metal components.With an unwavering commitment to quality and innovation, [Company Name] has continuously strived to deliver industry-leading solutions to its clients. Recognizing the importance of efficient and reliable bending machines in modern manufacturing processes, the company has invested significant resources into research and development to produce parts that meet the highest standards of performance.[Company Name] takes pride in its team of experienced engineers and technicians who have worked tirelessly to develop these state-of-the-art bending machine parts. By leveraging their expertise and utilizing the latest manufacturing technologies, the company ensures that each part delivers exceptional performance and longevity.One of the standout features of [Company Name]'s bending machine parts is their unparalleled efficiency. The parts are meticulously crafted to minimize friction and maximize energy transfer, resulting in faster and more precise bending processes. This not only saves time but also increases overall productivity, allowing manufacturers to meet tight deadlines while maintaining the highest quality standards.Durability is another key focus of [Company Name]'s new range of bending machine parts. Built with high-quality materials and subjected to rigorous testing, these parts are designed to withstand heavy usage and maintain their performance even in demanding industrial environments. By investing in these parts, manufacturers can significantly reduce maintenance costs and minimize production downtime, ensuring uninterrupted operations and maximizing their return on investment.Furthermore, [Company Name]'s bending machine parts offer exceptional precision, enabling manufacturers to achieve intricate bends and complex shapes with ease. This level of accuracy is crucial in industries like automotive, aerospace, and construction where even the slightest deviation can lead to costly rework or compromised structural integrity. With these parts, manufacturers can confidently produce components that meet the most stringent specifications and deliver superior end products.To further assist its customers, [Company Name] also provides comprehensive support services including installation guidance, maintenance tips, and troubleshooting assistance. The company understands that its clients' success depends not only on the quality of the parts but also on the reliability of its after-sales support. By offering a holistic approach, [Company Name] aims to foster long-term partnerships and ensure the continued satisfaction of its customers.[Company Name]'s dedication to innovation and customer satisfaction has earned it a formidable reputation in the manufacturing industry. Numerous companies have already experienced significant improvements in their bending processes and overall operational efficiency after incorporating these cutting-edge parts. With this latest release, [Company Name] reaffirms its commitment to providing the industry with top-of-the-line solutions that drive progress and pave the way for a more productive tomorrow.About [Company Name]:[Company Name] is a renowned manufacturer and provider of industrial machinery. With a strong emphasis on innovation and customer satisfaction, the company has continuously delivered cutting-edge solutions to various industries worldwide. From bending machines to CNC systems, [Company Name] is dedicated to revolutionizing manufacturing processes and helping businesses thrive in an ever-evolving market.For more information, please visit [Company Name]'s website at [website address] or contact [email/phone number].###Note: The text in {} indicates the need to remove the brand name and insert specific information about the company, such as its introduction and contact details.

High-Quality CNC Precision Turned Parts: An Essential Guide for Machining Success

Title: Advancements in CNC Precision Turned Parts Revolutionize Manufacturing ProcessesIntroduction:In today's rapidly changing technological landscape, precision engineering plays a critical role in driving innovation and efficiency across various industries. CNC Precision Turned Parts, offered by leading companies in the sector, have emerged as a game-changing solution in manufacturing processes. By leveraging the power of computer numerical control (CNC) technology, these parts offer unparalleled accuracy, reliability, and versatility, revolutionizing the way components are produced.Body: 1. Understanding CNC Precision Turned Parts:CNC Precision Turned Parts refer to intricately designed components manufactured using CNC turning machines. These machines utilize computer-controlled movements to produce parts with exceptionally high accuracy and repeatability. By utilizing a combination of rotating cutting tools and computer-controlled movements, CNC machining ensures precise dimensions, tolerances, and surface finishes, resulting in superior quality components.2. Advantages of CNC Precision Turned Parts:a) Enhanced Precision and Accuracy: The integration of CNC technology eliminates human error and enables the production of parts with microscopic tolerances, ensuring the highest level of precision possible.b) Efficiency and Speed: CNC machining processes significantly reduce production time, allowing for faster turnaround and increased productivity.c) Versatility: CNC turning machines are capable of manufacturing complex and intricate components from a wide range of materials, including metal alloys, plastics, and composites.d) Cost-effective Manufacturing: CNC Precision Turned Parts streamline production workflows, reducing labor costs and material waste while improving overall operational efficiency.e) Consistency and Reproducibility: CNC machining guarantees consistent quality and uniformity across multiple batches or order quantities, meeting stringent industry standards.3. Applications across Industries:CNC Precision Turned Parts have found applications across a wide array of industries, including:- Aerospace: CNC turned parts are crucial for manufacturing aircraft components, such as hydraulic fittings, fuel pumps, valves, and landing gear.- Automotive: Precision turned parts are extensively used in vehicle manufacturing processes, including engine components, transmission systems, and suspension parts.- Electronics: The electronics industry relies on CNC precision turned parts to produce connectors, enclosures, switches, and other intricate components used in various electronic devices.- Medical: CNC machining plays a pivotal role in healthcare, enabling the production of precise medical instruments, implants, prosthetics, and surgical components.- Defense: The defense sector benefits from CNC precision turned parts for creating specialized components used in military equipment, firearms, and armored vehicles.4. Cutting-Edge Technology and Innovation:Leading companies in the CNC Precision Turned Parts space, including (brand name), are continuously investing in cutting-edge technology and innovation to stay at the forefront of the industry:a) Advanced CNC Machinery: Investing in state-of-the-art CNC turning machines that offer multi-axis capabilities, high-speed machining, and advanced tooling options ensures superior product quality and greater manufacturing flexibility.b) Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): Utilizing sophisticated CAD/CAM software enables companies to optimize production processes, reduce errors, and enhance productivity.c) Quality Control and Inspection Systems: Implementing stringent quality control measures, such as advanced metrology equipment and comprehensive inspection protocols, ensure that each CNC precision turned part meets the highest international quality standards.d) Materials Research and Development: Collaborations with material scientists and researchers aid in the development of advanced materials that enhance the performance, durability, and efficiency of CNC precision turned parts.Conclusion:CNC Precision Turned Parts have revolutionized the manufacturing industry, offering unparalleled precision, productivity, and versatility. With advancements in CNC technology and a commitment to innovation, (brand name) and other prominent companies in the sector continue to push the boundaries of what is possible in precision engineering. As these parts become more widely adopted, industries across the board will benefit from increased efficiency, reduced costs, and improved product quality, paving the way for a more advanced and interconnected future.

Top Tips for Choosing a Plastic Box Mould

Plastic Box Mould has been making waves in the manufacturing industry, providing high-quality molds for plastic boxes that meet the needs of various industries. The company has a strong reputation for delivering innovative and reliable products, making it a go-to choice for businesses looking for top-notch molds.With years of experience in the industry, Plastic Box Mould has emerged as a leader in the field, offering a wide range of mold options to suit the specific requirements of its clients. From food and beverage packaging to industrial storage solutions, the company has the expertise to deliver custom molds that meet the highest standards of quality and precision.The key to the company's success lies in its commitment to technological advancement and continuous improvement. Plastic Box Mould has invested heavily in state-of-the-art manufacturing equipment and processes, allowing it to stay ahead of the curve and provide its clients with the most cutting-edge mold solutions available.In addition to its technical prowess, the company also prides itself on its customer-centric approach. Plastic Box Mould works closely with its clients to understand their unique needs and specifications, ensuring that the final product not only meets but exceeds expectations. This dedication to customer satisfaction has earned the company a loyal client base, with many businesses choosing to partner with Plastic Box Mould for all their mold needs.One of the company's flagship offerings is its line of plastic box molds, which are used in a wide range of applications across various industries. These molds are designed to be durable, versatile, and cost-effective, making them an ideal choice for businesses looking to streamline their manufacturing processes and reduce production costs. Whether it's for food packaging, storage containers, or other industrial uses, Plastic Box Mould has the expertise and capabilities to deliver molds that are tailored to each client's unique requirements.Furthermore, Plastic Box Mould is committed to sustainability and environmental responsibility. The company places a strong emphasis on using eco-friendly materials and processes in its manufacturing operations, ensuring that its products have minimal impact on the environment. This approach not only benefits the planet but also resonates with businesses looking to align with sustainable practices and reduce their carbon footprint.Looking ahead, Plastic Box Mould is poised for even greater success as it continues to innovate and expand its product offerings. The company is constantly exploring new technologies and materials to push the boundaries of mold manufacturing, all while maintaining its unwavering commitment to quality and customer satisfaction.In conclusion, Plastic Box Mould is a trusted name in the mold manufacturing industry, known for its innovative products and customer-centric approach. With a focus on technological advancement, sustainability, and exceeding client expectations, the company is well-positioned to lead the way in providing high-quality molds for plastic boxes and other applications. Businesses in need of reliable and cost-effective mold solutions can trust Plastic Box Mould to deliver the best in the industry.

CNC Turning Milling Parts: The Latest News on High-Quality Manufacturing

[Company name], a leading manufacturer in the field of CNC turning milling parts, continues to thrive in the competitive industry by delivering high-quality products and services. With an unyielding commitment to innovation and customer satisfaction, the company has established itself as a reliable partner for businesses in need of precision machined parts.CNC turning milling is a versatile machining process that involves the removal of material to create complex components. This manufacturing method utilizes computer-controlled machines to accurately and efficiently shape various materials, such as metals, plastics, and wood. It is widely used in industries such as automotive, aerospace, electronics, and telecommunications, where precision and quality are of utmost importance.With a strong focus on technological advancement, [Company name] has invested heavily in state-of-the-art CNC machines and cutting-edge software to provide its customers with products that meet and exceed their expectations. The company's cutting-edge equipment, coupled with a team of highly skilled engineers and technicians, ensures the delivery of reliable and precise CNC turning milling parts.What sets [Company name] apart from its competitors is its ability to provide customized solutions tailored to the specific needs of its clients. The company's experienced engineers work closely with customers to understand their requirements and design parts that meet their exact specifications. The flexibility offered by [Company name] allows businesses to optimize their manufacturing processes and save both time and money.Moreover, [Company name] has established a comprehensive quality control system to guarantee the reliability and accuracy of its products. Each CNC turning milling part undergoes stringent inspections and tests at every stage of the production process to ensure it meets the highest industry standards. This commitment to quality has earned [Company name] a reputation for excellence and has made it a trusted partner for businesses worldwide.In addition to its dedication to delivering top-notch products, [Company name] also prides itself on providing exceptional customer service. The company's team of professionals is readily available to assist clients from the early stages of design to the final delivery of the machined parts. The prompt and efficient communication offered by [Company name] ensures that customers' needs are met in a timely manner, fostering long-term relationships based on trust and satisfaction.Furthermore, [Company name] recognizes the importance of sustainable manufacturing practices and is committed to minimizing its environmental impact. The company adheres to strict environmental standards and continuously invests in eco-friendly technologies to reduce energy consumption and waste generation. By prioritizing sustainability, [Company name] aims to contribute to a greener and more sustainable future.As [Company name] continues to grow and expand its operations, it remains dedicated to its core values of innovation, quality, customer service, and sustainability. With a proven track record of delivering superior CNC turning milling parts, the company is well-positioned to meet the evolving needs of a diverse range of industries.In conclusion, [Company name] is a leading manufacturer of CNC turning milling parts, offering customized solutions, exceptional quality, and outstanding customer service. As the company embraces technological advancements and emphasizes sustainability, it remains a reliable partner for businesses worldwide, providing them with the precision machined parts they need to thrive in their respective industries.